Table of Contents

Hans Turck GmbH & Co. KG | T +49 208 4952-0 |

[email protected] | www.turck.com

V01.00 | 2022/09 | 2Table of Contents

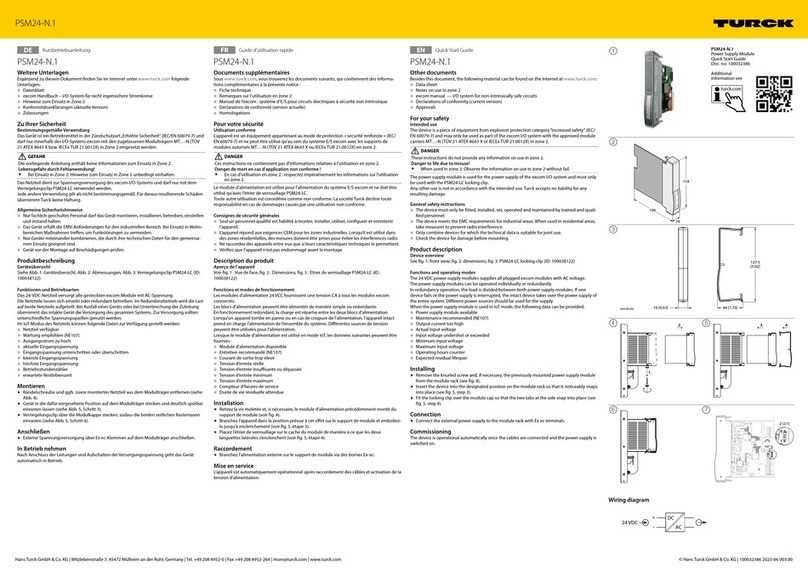

1 About these instructions ...................................................................................................................5

1.1 Target groups ...................................................................................................................5

1.2 Explanation of symbols used.........................................................................................5

1.3 Additional documents ....................................................................................................5

1.4 Feedback about these instructions ..............................................................................5

2 Notes on the product .........................................................................................................................6

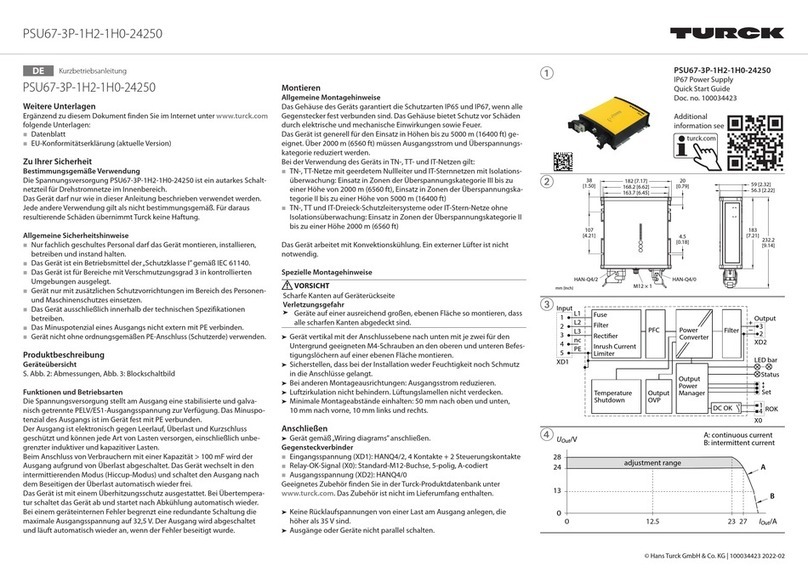

2.1 Product identification .....................................................................................................6

2.2 Scope of delivery..............................................................................................................6

2.3 Turck service .....................................................................................................................6

3 For your safety.....................................................................................................................................7

3.1 Intended use .....................................................................................................................7

3.1.1 Foreseeable misuse .........................................................................................................................7

3.2 General safety notes........................................................................................................7

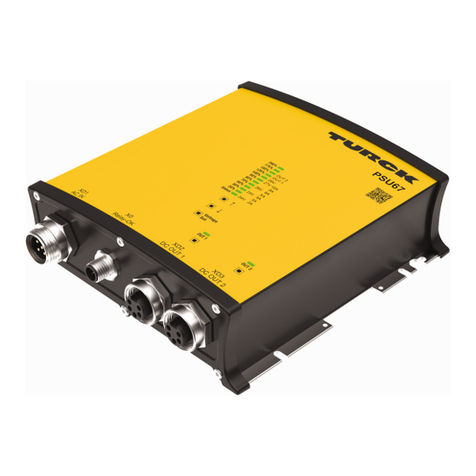

4 Product description ............................................................................................................................8

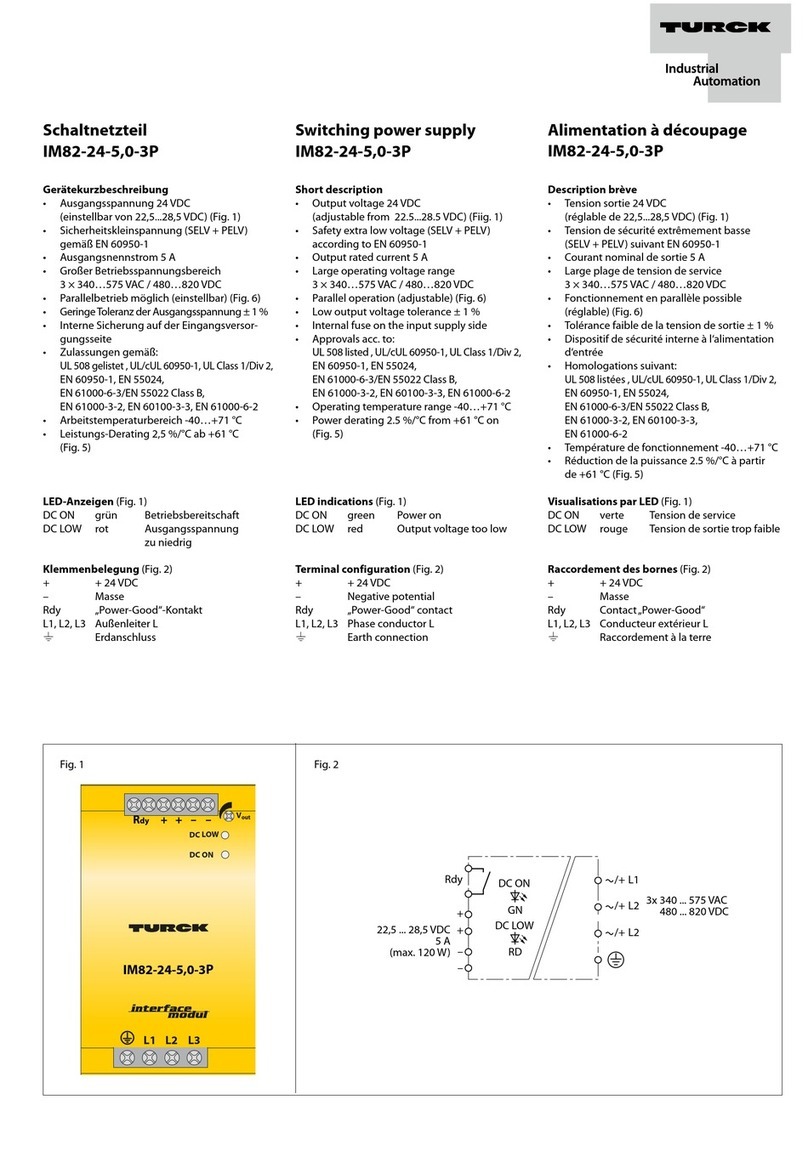

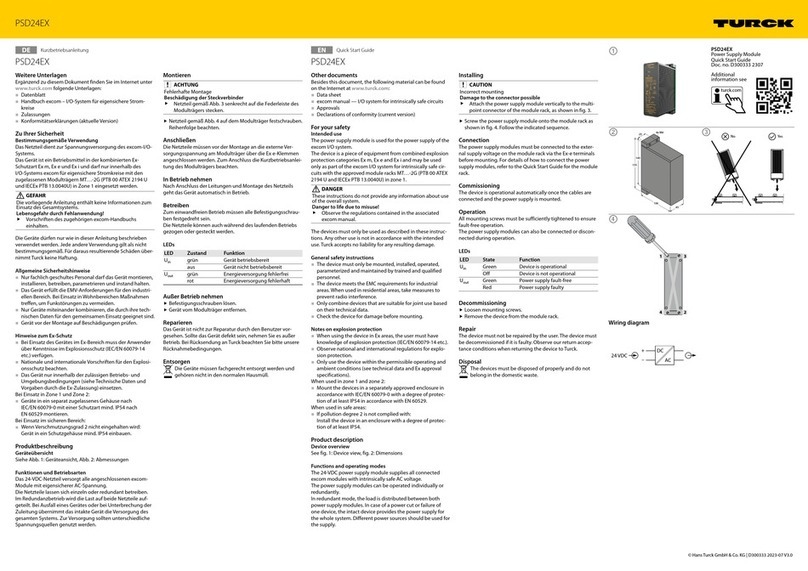

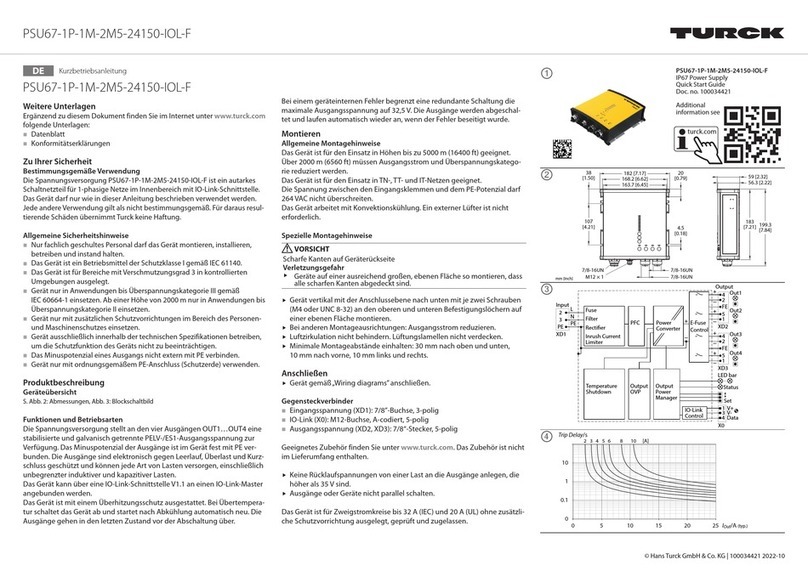

4.1 Device overview...............................................................................................................8

4.1.1 Block diagram....................................................................................................................................9

4.1.2 Operating elements.........................................................................................................................9

4.1.3 Display elements ..............................................................................................................................9

4.2 Properties and features ..................................................................................................9

4.3 Functional principle ........................................................................................................9

4.4 Functions and operating modes................................................................................ 10

4.4.1 User interface.................................................................................................................................. 10

4.4.2 AC voltage input............................................................................................................................ 10

4.4.3 DC voltage outputs....................................................................................................................... 11

4.4.4 IO-Link interface............................................................................................................................. 13

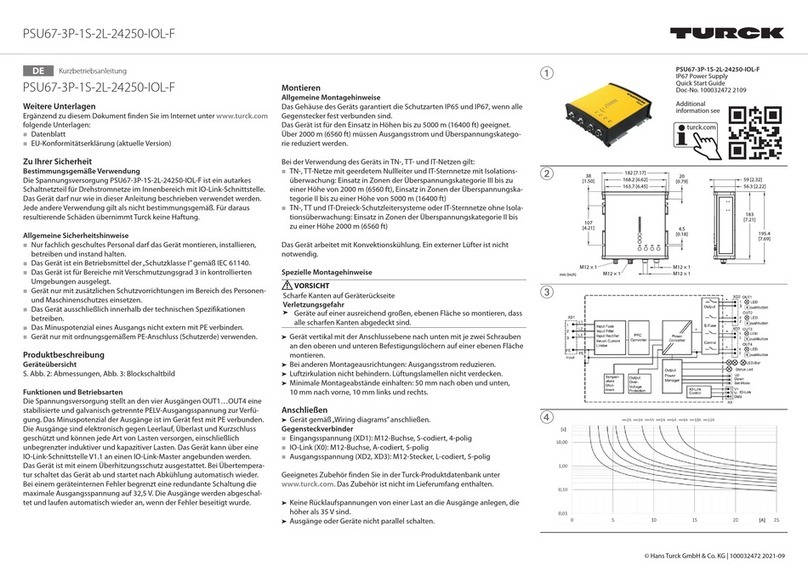

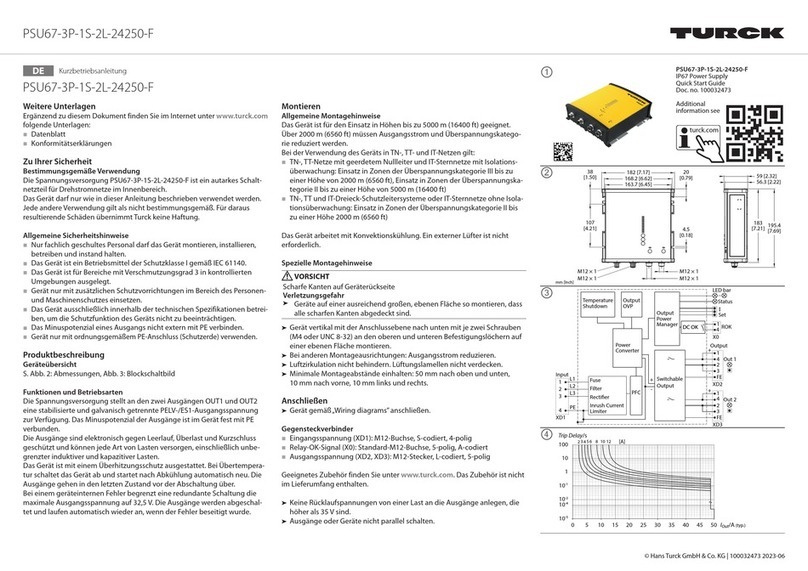

5 Installing ............................................................................................................................................ 14

5.1 Special installation instructions – mounting altitude ........................................... 14

6 Connecting ........................................................................................................................................ 15

6.1 Connecting the AC input voltage .............................................................................. 15

6.2 Connecting the DC output voltage side................................................................... 15

6.3 Connecting the device to IO-Link .............................................................................. 15

7 Commissioning................................................................................................................................. 16

8 Setting................................................................................................................................................ 17

8.1 Setting the device via LED bar and pushbuttons ................................................... 17

8.1.1 Switching outputs on or off....................................................................................................... 17

8.1.2 Resetting outputs.......................................................................................................................... 17

8.1.3 Activating and deactivating the button lock ...................................................................... 17

8.2 Setting the device via IO-Link..................................................................................... 18

8.2.1 Direct Parameter Page 1 ............................................................................................................. 18

8.2.2 Identification................................................................................................................................... 18

8.2.3 Index 0x02: System commands (according to IO-Link specification)......................... 19

8.2.4 Index 0x0C: Device Access Locks............................................................................................. 19

8.2.5 Parameters....................................................................................................................................... 20