moves upward. With the Poppet As-

sembly in the full up position, water

flow is diverted from the Domestic

Flow Passage to the Fire Sprinkler

Flow Passage. After the Poppet As-

sembly has moved to the full up posi-

tion, only a small amount of water is

permitted to trickle through the By-

Pass Restriction to the Domestic Port.

The trickle flow through the By-Pass

Restriction permits automatic resetting

of the F540 Valve, without draining of

the fire sprinkler system, after a sprink-

ler operation or test. When the Manual

Domestic Shutoff Valve is closed, the

By-Pass Restriction allows the Supply

and Domestic Port pressures to equal-

ize and the Poppet Assembly to move

back down to the standby position. The

maximum flow rate through the By-

Pass Restriction, when the F540 Valve

is in the operated position is less than

l/4 GPM (0,9 LPM) for a typical resid-

ual (flowing) pressure of 40 psi (2,8

bar) at the inlet. Consequently, it is not

necessary to take into account the

trickle flow through the F540 Valve By-

Pass Restriction, into the domestic

system, when performing hydraulic de-

sign calculations for the fire sprinkler

system.

The contours of the Poppet Assembly

have been specifically configured to

minimize its upward movement except

under the level of sustained fire sprink-

ler system flow resulting from opera-

tion of a fire sprinkler. However, be-

cause most fire sprinkler systems

contain air pockets, the Poppet As-

sembly will tend to move momentarily

upward if there is a surge in supply

pressure. The momentary opening

and reclosing of the Poppet Assembly

at the Fire Sprinkler Seat will trap a

portion of the pressure increase within

the fire sprinkler system. The trapping

of pressure increases within the fire

sprinkler system will help to reduce the

possibility of a subsequent surge in the

supply pressure from causing the

waterflow detector to signal a false

alarm.

As indicated above, domestic system

usage may reduce the pressure avail-

able to the fire sprinkler system. How-

ever, when utilizing the F540 Valve, it

is not necessary to take into account

the complex hydraulic modeling of the

domestic system, that would otherwise

be required to determine the minimum

possible residual (flowing) pressure

which would be available to the fire

sprinkler system.

For operation of the F540 Valve, it is

only necessary to design the fire

sprinkler system, from the water main

to the most hydraulicaly remote sprink-

ler, to provide a minimum single sprink-

ler flow of 12.5 GPM (47,3 LPM), when

the supply pressure at the main is at its

minimum expected value.

6.0

5.0

1.0

0.9

0.8

0.7

0.6

0.5

0.2

0.1 5 6 7 8910 20 30 40 50

FLOW RATE IN GALLONS PER MINUTE (GPM)

FIGURE C

NOMINAL PRESSURE LOSS VERSUS FLOW

NOTE NOTE

A fire sprinkler water supply connec-

tion to a public water supply is usu-

ally subject to local regulations con-

cerning metering and backflow

prevention requirements. Consult

with the local water authorities con-

cerning local requirements which

may apply to the arrangement of these

components in the fire sprinkler sys-

tem water supply.

A spring loaded check valve is not to

be installed between the F540 Valve

and the fire sprinklers.

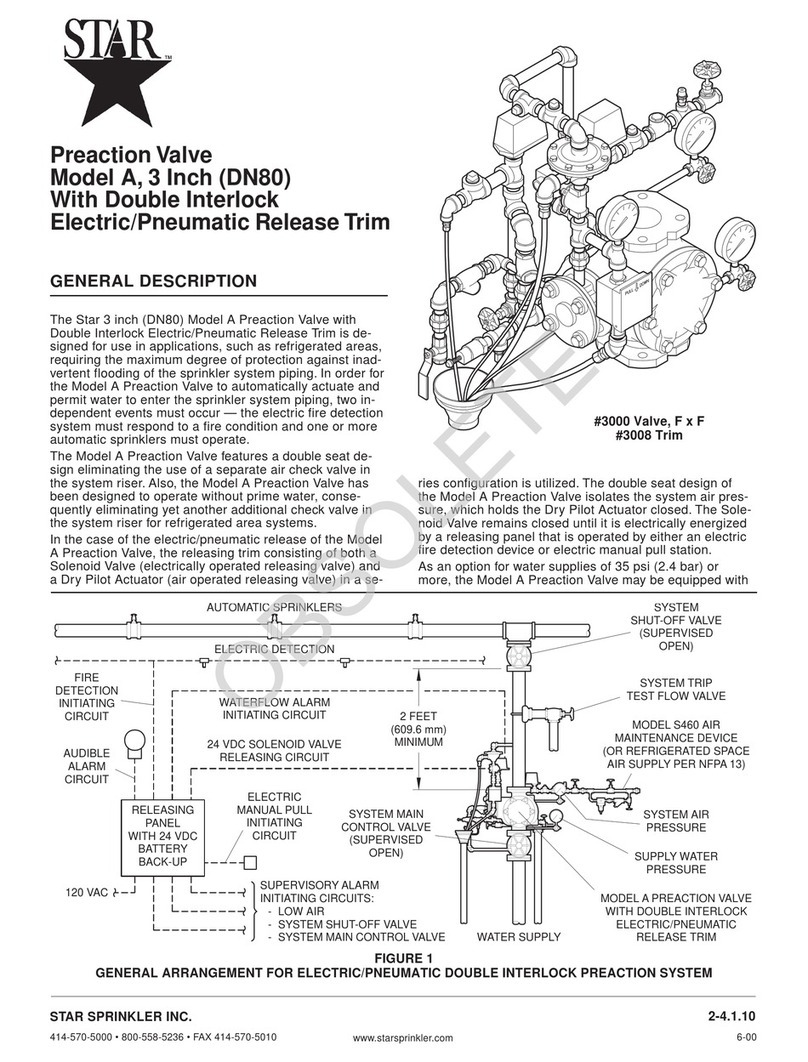

Figure A illustrates a typical arrange-

ment using the Model F540 Residen-

tial Domestic Shutoff Valve. The ar-

rangement may need to be modified to

meet the requirements of the authority

having jurisdiction; however, the

Model F540 Residential Domestic

1. The F540 Valve is to be installed

vertically with the Supply Port at the

bottom, the Fire Sprinkler Port at the

top, and the Domestic Port at the

side. It is recommended that a suit-

able clamp be installed along the

water supply riser piping, to provide

support for the weight of the F540

Valve.

2. The maximum water supply service

line is to be 1 inch (25mm).

3. The water supply to the F540 Valve

-3-

Shutoff Valve must be installed in ac-

cordance with the following criteria: