Design

Criteria

Obtain guidance for the design of a wa-

ter-mist system that utilizes the TYCO

Type ULF AM27 AQUAMIST Nozzles

from the Technical Services department.

Installation

The TYCO Type ULF AM27 AQUAMIST

Nozzles must be installed in accordance

with the following instructions.

NOTICE

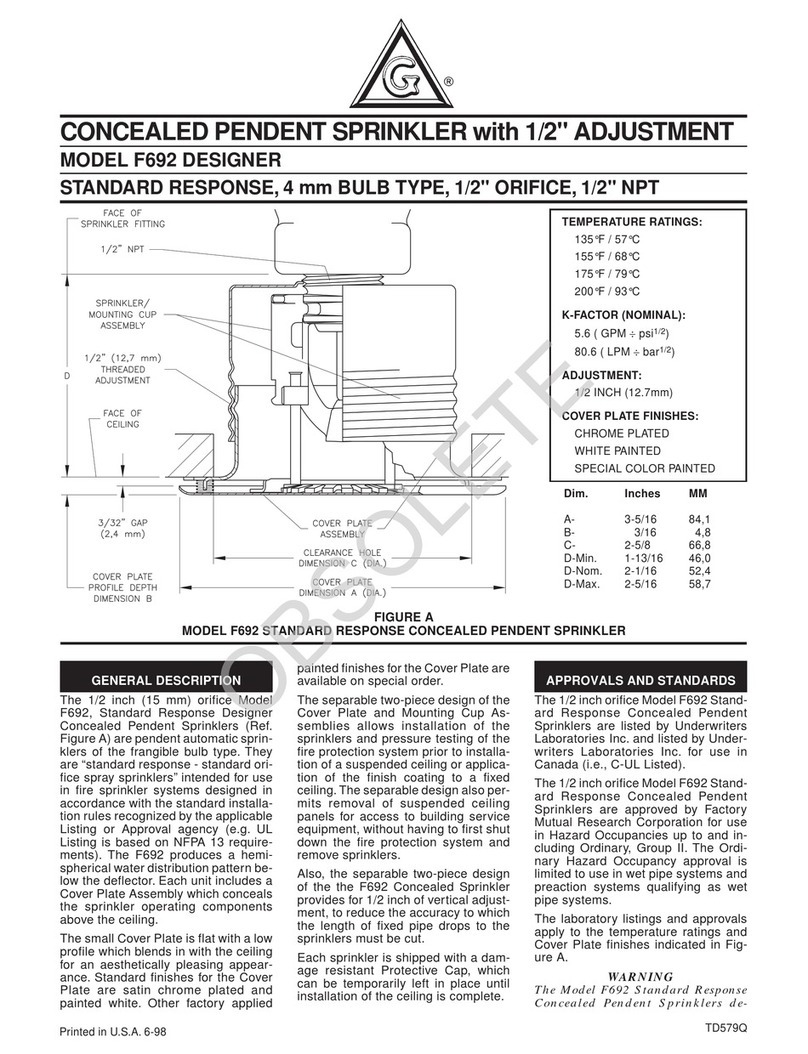

Do not install any bulb-type nozzle if the

bulb is cracked or there is a loss of liq-

uid from the bulb. With the nozzle held

horizontally, a small air bubble should be

present. The diameter of the air bubble

is approximately 1,6 mm (1/16 inch) for

the 57°C/135°F to 2,4 mm (3/32 inch)

for the 93°C/200°F temperature ratings.

Obtain a leak-tight 1/2 inch NPT nozzle

joint by applying a minimum-to-maxi-

mum torque of 9,5 to 19,0 Nm (7 to 14

ft.-lbs.). Higher levels of torque can dis-

tort the nozzle inlet and cause leakage

or impairment of the nozzle.

Do not attempt to compensate for insuffi-

cient adjustment in the escutcheon plate

by under or over-tightening the nozzle.

Re-adjust the position of the nozzle fit-

ting to suit.

Type ULF AM27

The Type ULF AM27 AQUAMIST Nozzles

must be installed in accordance with

the following instructions.

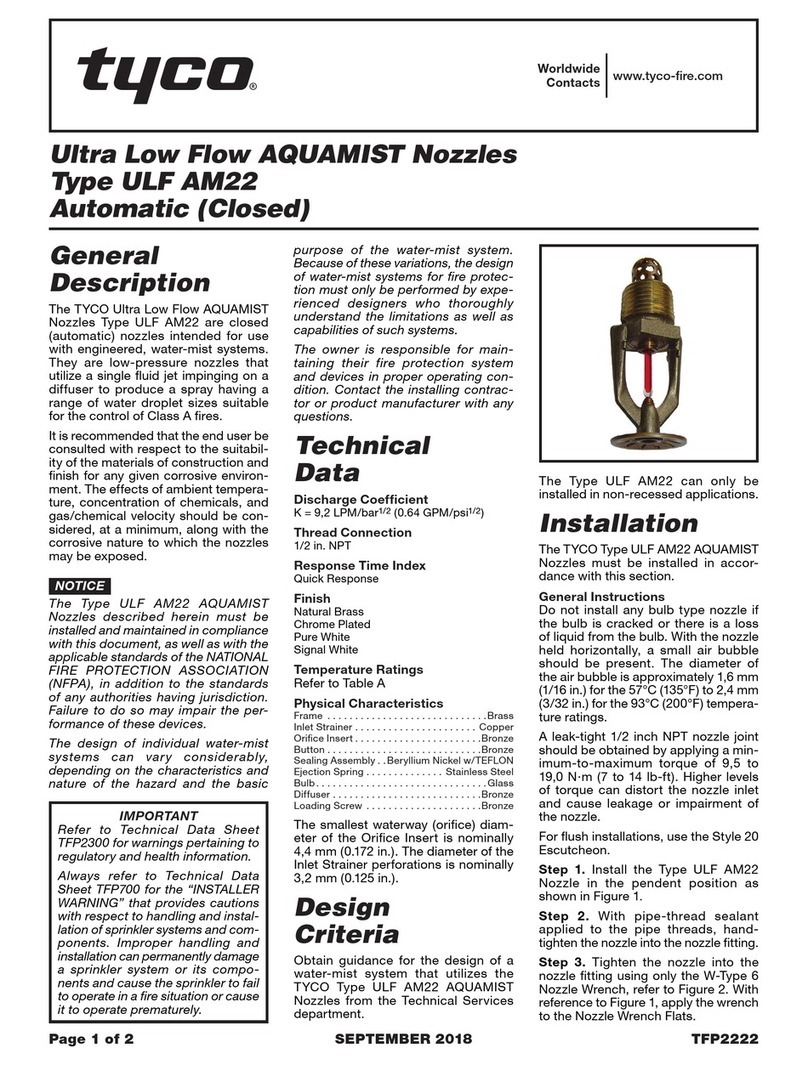

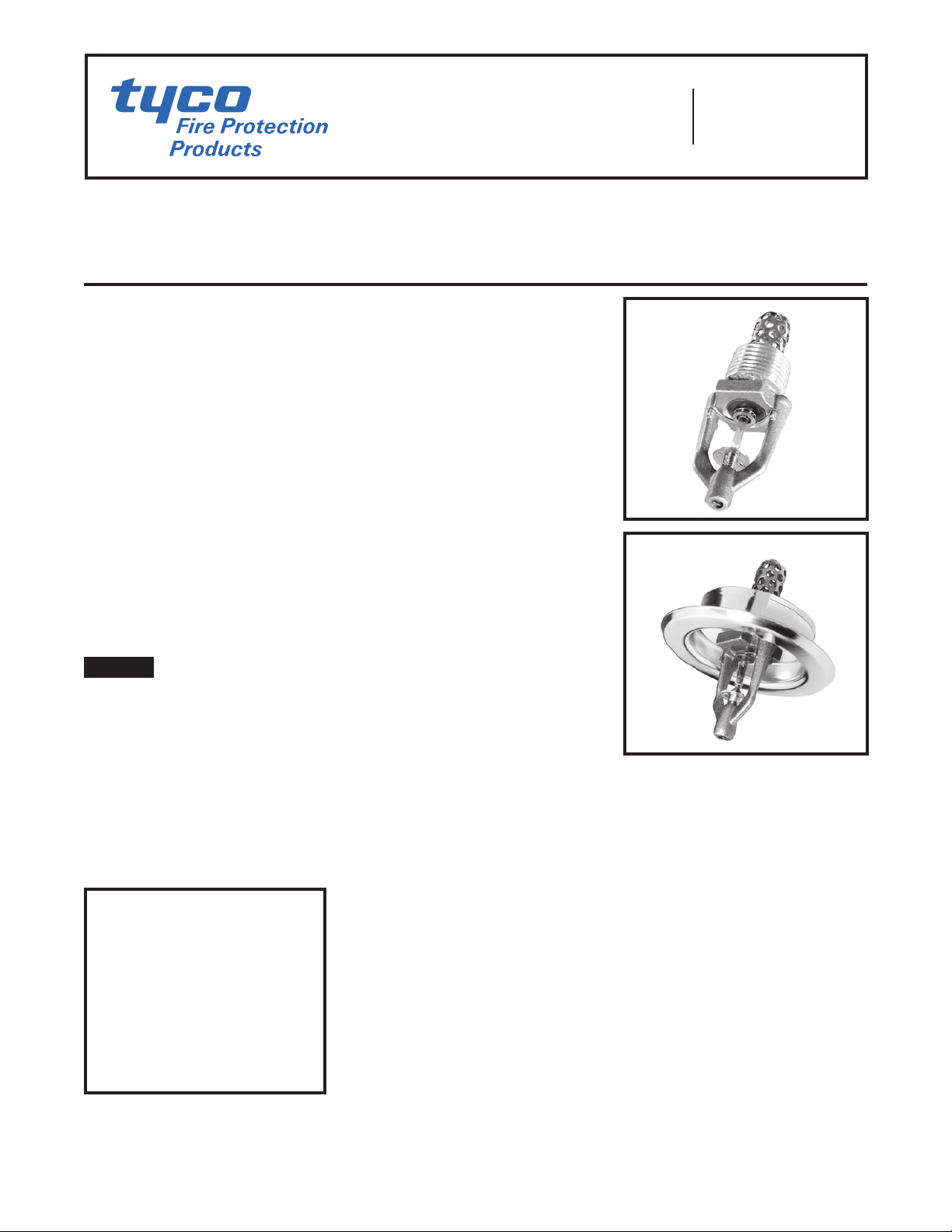

Step 1. Install the Type ULF AM27 in the

pendent position as shown in Figure 1.

Step 2. With pipe-thread sealant ap-

plied to the pipe threads, hand-tighten

the nozzle into the nozzle fitting.

Step 3. Tighten the nozzle into the

nozzle fitting using only the W-Type 6

Wrench (refer to Figure 3). With refer-

ence to Figure 1, apply the W-Type 6

Wrench to the Wrench Flats.

Type ULF AM27 Recessed

The Type ULF AM27 AQUAMIST Re-

cessed Nozzles must be installed in ac-

cordance with the following instructions.

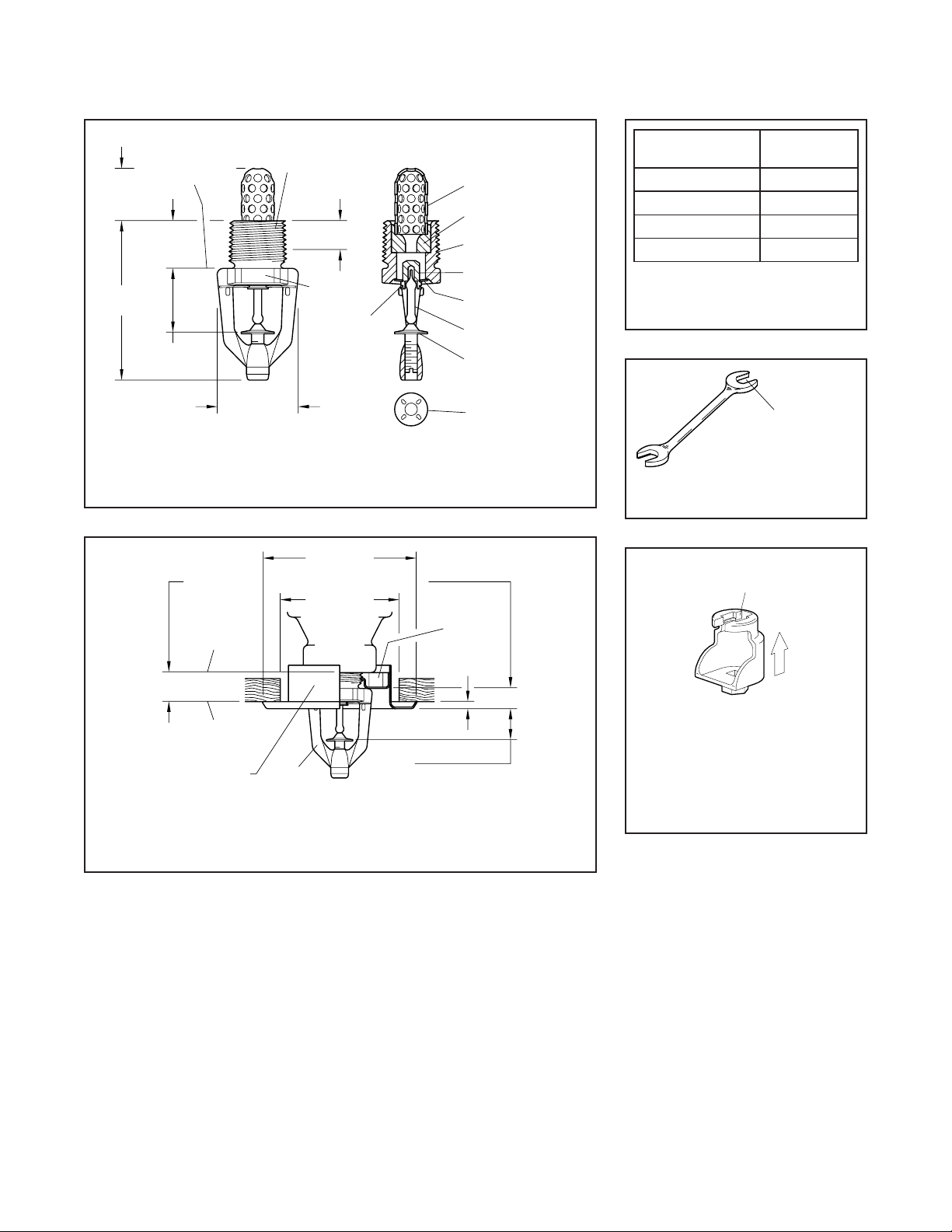

Step 1. Install the Recessed Type ULF

AM27 in the pendent position as shown

in Figure 2.

Step 2. After installing the Style 20

Mounting Plate, as applicable, over the

nozzle threads and with pipe-thread seal-

ant applied to the pipe threads, hand-

tighten the nozzle into the nozzle fitting.

Step 3. Tighten the nozzle into the nozzle

fitting using only the W-Type 7 Wrench

(refer to Figure 4). With reference to

Figure 1, apply the W-Type 7 Wrench

to the nozzle Wrench Flats.

Step 4. After the ceiling has been in-

stalled or the finish coat has been ap-

plied, slide on the Style 20 Closure over

the Type ULF AM27 Nozzle and push

the Closure over the Mounting Plate

until its flange comes in contact with

the ceiling.

Care and

Maintenance

The TYCO Type ULF AM27 AQUAMIST

Nozzles must be maintained and ser-

viced in accordance with the following

instructions.

NOTICE

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system that

it controls, obtain permission to shut

down the affected fire protection system

from the proper authorities and notify

all personnel who may be affected by

this action.

Absence of an escutcheon, which is

used to cover a clearance hole, can

delay the time to nozzle operation in a

fire situation.

Exercise care to avoid damage to Type

ULF AM27 Nozzles before, during and

after installation. Never paint, plate,

coat, or otherwise alter nozzles after

they leave the factory.

To prevent impaired performance, re-

place nozzles that:

• were modified or over-heated.

• were damaged by dropping, strik-

ing, wrench twisting, wrench slip-

page, or the like.

• are leaking or showing visible signs

of corrosion.

• were exposed to corrosive products

of combustion but not operated if

they cannot be completely cleaned

by wiping the nozzle with a cloth

or by brushing it with a soft bristle

brush.

• have a cracked bulb or have lost liq-

uid from the bulb. (Refer to the In-

stallation section.)

Frequent visual inspections are recom-

mended to be initially performed for

nozzles installed in potentially corro sive

atmospheres to verify the integrity of the

materials of construction and finish as

they may be affected by the corrosive

conditions present for a given instal-

lation. Thereafter, annual inspections

per NFPA 25 are required, in addition

to inspections required by the authority

having jurisdiction.

Responsibility lies with the owner for the

inspection, testing, and maintenance of

their fire protection system and devices

in compliance with this document, as

well as with the applicable standards of

the National Fire Protection Association

(for example, NFPA 20, 25, and 750), in

addition to the standards of any other

authorities having jurisdiction. Contact

the installing contractor or sprinkler

manufacturer regarding any questions.

Water-mist fixed systems should be in-

spected, tested, and maintained by a

qualified Inspection Service in accor-

dance with local requirements and/or

national codes.

TFP2227

Page 3 of 4