2. Remove the Protective Cap.

3. With pipe thread sealant applied to

the pipe threads, and using the

Model 2111 Wrench positioned as

showninFigureD,install andtighten

the F692 Sprinkler/Mounting Cup

Assembly into the fitting. The 2111

will accept a 1-1/16 inch hex socket

or a 1/2 inch ratchet drive.

4. Refer to Figure E and replace the

Protective Cap by pushing it up-

wardsuntilitbottoms out against the

Mounting Cup. The Protective Cap

helps prevent damage to the Deflec-

tor and Arms during ceiling installa-

tion and/or during application of the

finish coating of the ceiling. It may

also be used to locate the center of

theclearance holebygentlypushing

the ceiling material up against the

center point of the Cap.

Open the Protective Cap as shown

in Figure E, if the fire protection sys-

tem is to be in service while the

ceiling installation is being com-

pleted.

5. After theceilinghasbeencompleted

withthe2-5/8inch (66,7mm)diame-

ter clearance hole, remove and dis-

card the Protective Cap, and verify

that the Deflector moves up and

down freely.

If the F692 Sprinkler has been dam-

aged and the Deflector does not

move up and down freely, replace

the entire F692 Sprinkler assembly.

Do not attempt to modify or repair a

damaged sprinkler.

6. Screw-on the Cover Plate Assembly

until its flange just comes in contact

with the ceiling.

Do not continue to screw-on the

Cover Plate Assembly such that it

lifts a ceiling panel out of its normal

position.

If the Cover Plate Assembly cannot

be engaged with the Mounting Cup

or the Cover Plate Assembly cannot

be engaged sufficiently to contact

the ceiling, the Sprinkler has been

positioned incorrectly and must be

repositionedaccording toStepNo.1.

CARE AND MAINTENANCE

Automatic sprinklers must never be

shippedorstoredwheretheirtempera-

ture will exceed 100°F/38°C and they

must never be painted, plated, coated

or otherwise altered after leaving the

factory.Modified sprinklers must be re-

placed. Sprinklers that have been ex-

posed to corrosive products of com-

bustion, but have not operated, should

be replaced if they cannot be com-

pletely cleaned by wiping the sprinkler

with a cloth or by brushing it with asoft

bristle brush.

Care must be exercised to avoid dam-

age to the sprinklers - both before and

after installation. Sprinklers damaged

by dropping, striking, wrench

twist/slippage, or the like, must be re-

placed.Also, replace any sprinkler that

has a cracked bulb or that has lost

liquid from its bulb. (Ref. Installation

Section).

If a sprinkler must be removed for

some reason, do not reinstall it or a

replacement without reinstalling the

Cover Plate Assembly.If a Cover Plate

Assembly becomes dislodged during

service, replace it immediately.

NOTES

1. Absence of the Cover Plate Assem-

bly may delay sprinkler operation

in a fire situation.

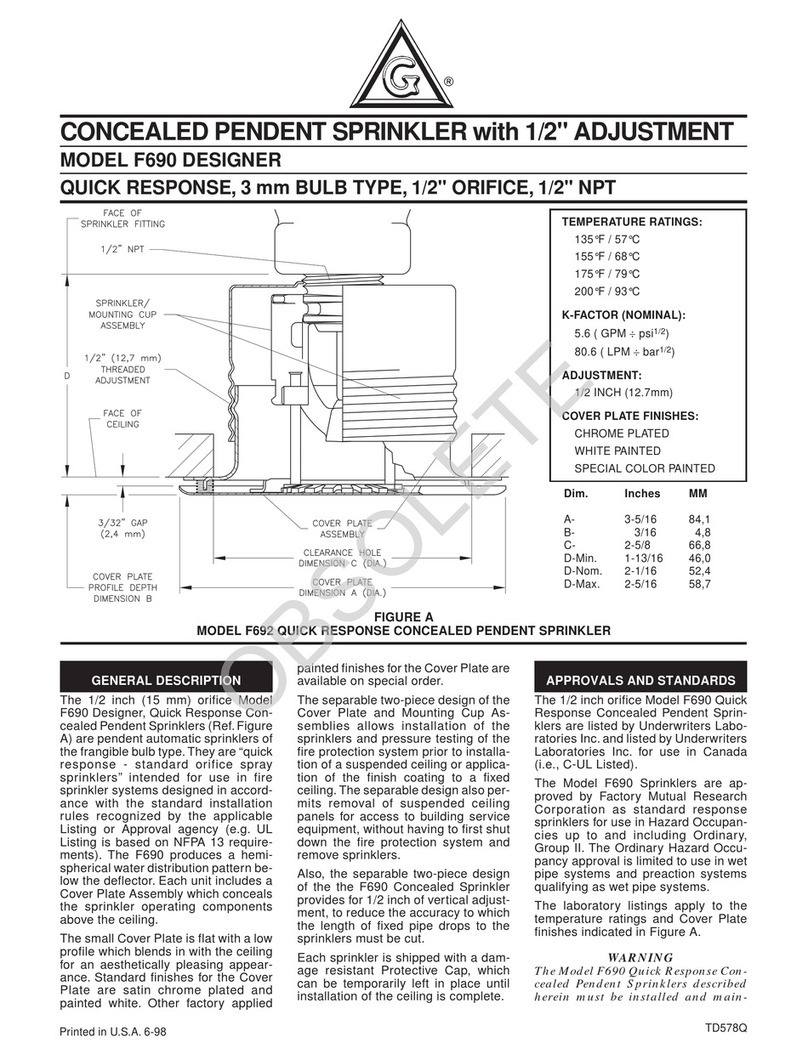

2. When properly installed, there is a

nominal 3/32 inch (2,4 mm) air

gap between the lip of the Cover

Plate and the ceiling, as shown in

Figure A. This air gap is necessary

for proper operation of the sprin-

kler. If the ceiling is to be repainted

after the installation of the F692,

care must be exercised to ensure

that the new paint does NOT seal

off any of the air gap

3. Factory painted Cover Plates

MUST NOT be repainted. They

should be replaced, if necessary, by

factory painted units.

4. Do not pull the Cover Plate relative

to the Enclosure. Separation may

result.

5. Before closing a fire protection sys-

tem main control valve for mainte-

nance work on the fire protection

system which it controls, permis-

sion to shut down the affected fire

protection system must be obtained

from the proper authorities and all

personnel who may be affected by

this action must be notified.

It is recommended that automatic

sprinkler systems be inspected quar-

terly by a qualified Inspection Service.

WARRANTY

Seller warrants for a period of one year

from the date of shipment (warranty

period) that the products furnished

hereunder will be free from defects in

material and workmanship.

For further details on Warranty, see

Price List.

ORDERING PROCEDURE

Sprinkler Assemblies:

Specify: 1/2 inch orifice, (specify tem-

perature rating), Model F692Standard

Response Concealed Pendent Sprin-

kler with (specify type finish) Cover

Plate, PSN (specify from Table 2).

Contact your local distributor for avail-

ability.

Product Symbol Numbers are not

specified when ordering F692 Sprin-

klers with a special painted finish for

the Cover Plate. It is suggested that a

color chip be provided when ordering

specialpaintedfinishes.Otherwise,re-

sponsibility for duplication of the de-

sired finish cannot be accepted.

Separately Ordered Parts:

Specify: Model 2111 Sprinkler

Wrench, PSN 56-000-2-111.

Replacement Parts:

Specify: (description) for use with

F692 Sprinklers, PSN (specify).

Sprinkler/Mounting Cup Assemblies

arenotavailableasreplacementparts.

Painted White

135°F/57C Cover Plate Assembly

for 135°F/57°C or 155°F/68°C Sprinklers

. . . . . . . . . . . . . . . . . . . . . . PSN 56-690-0-155

Painted White

165°F/74C Cover Plate Assembly

for 175°F/ 79°C or 200°F/93°C Sprinklers

. . . . . . . . . . . . . . . . . . . . . . PSN 56-690-0-200

Chrome Plated

135°F/57C Cover Plate Assembly

for 135°F/57°C or 155°F/68°C Sprinklers

. . . . . . . . . . . . . . . . . . . . . . PSN 56-690-9-155

Chrome Plated

165°F/74C Cover Plate Assembly

for 175°F/ 79°C or 200°F/93°C Sprinklers

. . . . . . . . . . . . . . . . . . . . . . PSN 56-690-9-200

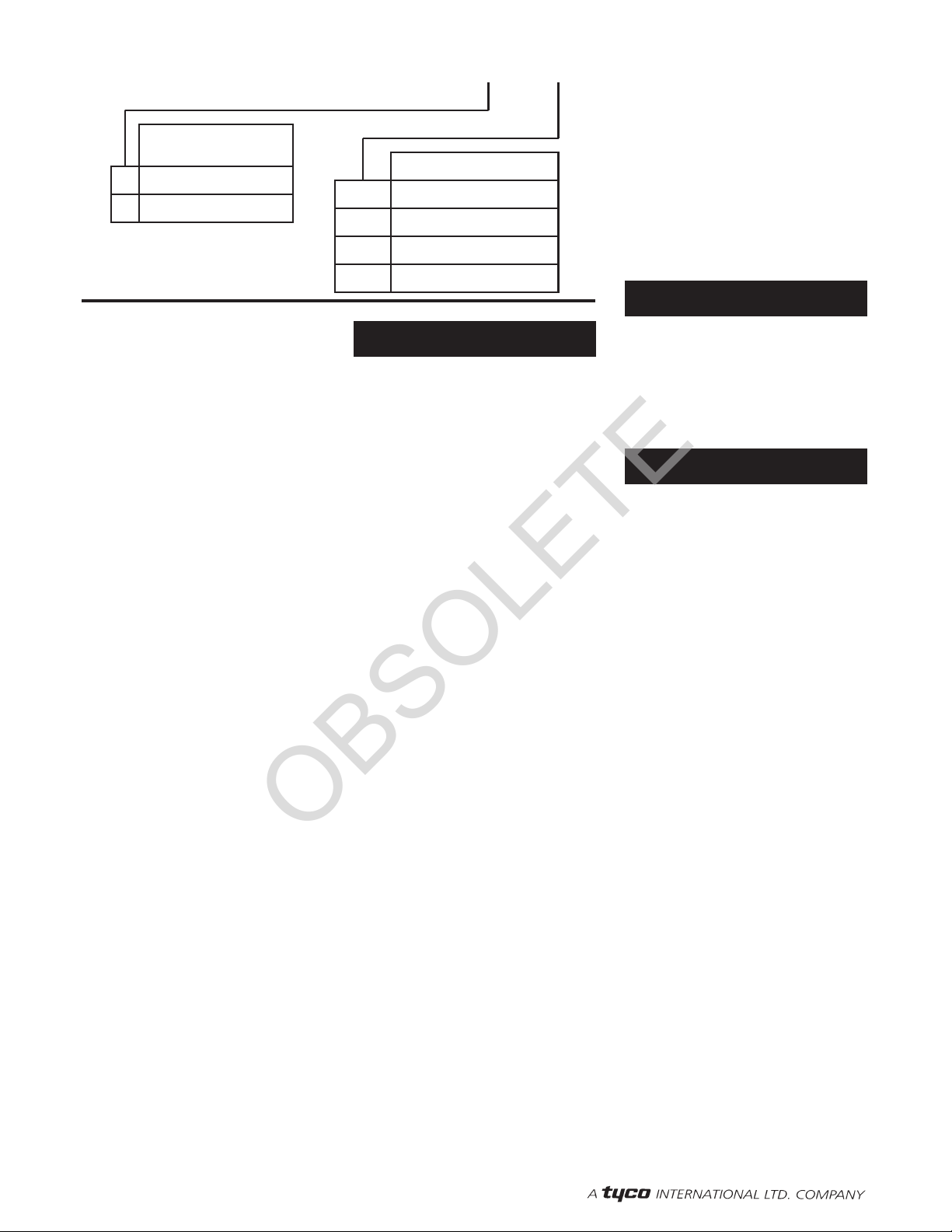

PSN51 -692-X- XXX

9

0

COVER PLATE

FINISH

Chrome Plated

Painted White 155

TEMPERATURE RATING

155°F/68°C

TABLE 2

PRODUCT SYMBOL NUMBER

SELECTION 200 200°F/93°C

135°F/57°C

175°F/79°C175

135

® Reg.trademark of GRINNELL CORPORATION, 3 TYCO PARK, EXETER, NH 03833