TFP151

Page 7 of 8

Do not attempt to make-up for insuf-

cient adjustment in the escutcheon

plate by under- or over-tightening the

sprinkler. Readjust the position of the

sprinkler tting to suit.

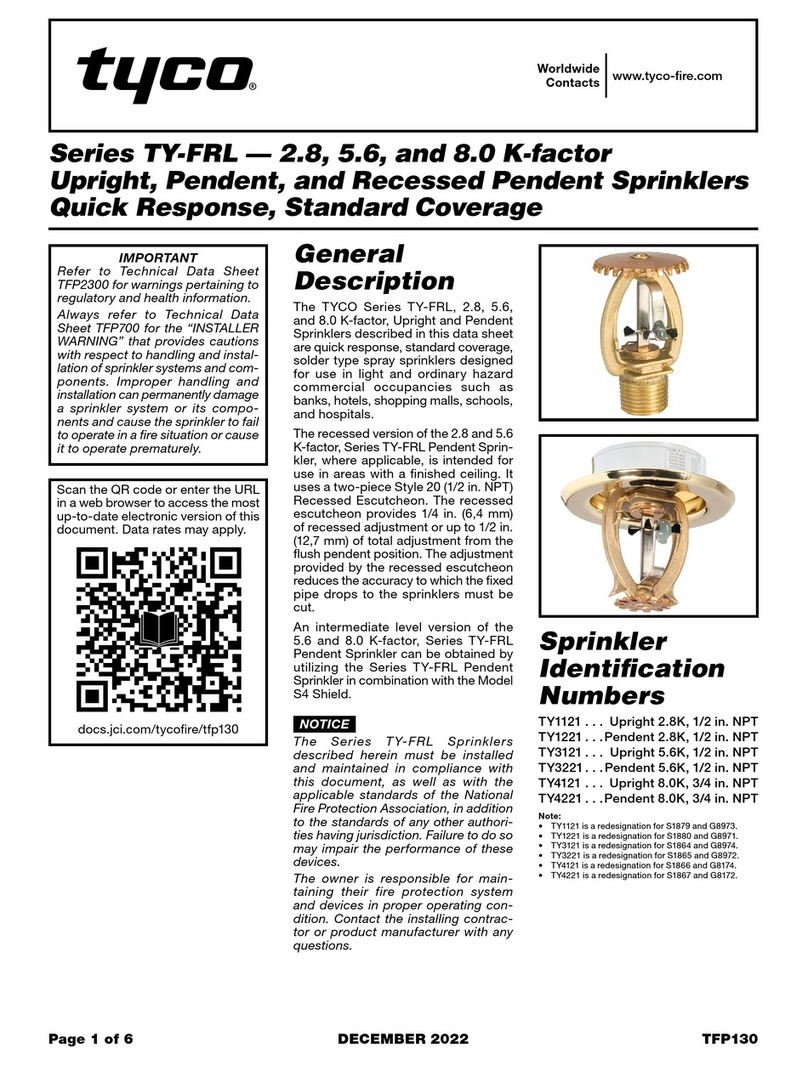

Upright and Pendent Sprinklers

The Series TY-B Upright and Pendent

Sprinklers must be installed in accor-

dance with the following instructions.

Step 1. Install pendent sprinklers in

the pendent position; install upright

sprinklers in the upright position.

Step 2. With pipe-thread sealant

applied to the pipe threads, hand-

tighten the sprinkler into the sprinkler

tting.

Step 3. Tighten the sprinkler into the

sprinkler tting using only the W-Type

6 Sprinkler Wrench (Figure 7). For

wax-coated sprinklers, use an 8 or

10 inch adjustable Crescent wrench.

With reference to Figures 1 through 4,

apply the W-Type 7 Sprinkler Wrench

or the adjustable Crescent wrench,

as applicable is to be applied to the

wrench ats.

When installing wax-coated sprinklers

with the adjustable Crescent wrench,

exercise care to prevent damage to the

wax coating on the sprinkler wrench

ats or frame arms and, consequently,

exposure of bare metal to the corrosive

environment. Open the jaws of the

wrench sufciently wide to pass over

the wrench ats without damaging the

wax coating. Before wrench tightening

the sprinkler, adjust the jaws of the

wrench to contact only the sprinkler

wrench ats. After wrench tightening

the sprinkler, loosen the wrench jaws

before removing the wrench.

After installation, inspect the sprinkler

wrench ats and frame arms and

retouch (repair) the wax coating when-

ever the coating has been damaged

and bare metal is exposed. Retouch

the wax coating on the wrench ats

by gently applying a heated 1/8 inch

diameter steel rod to the damaged

areas of wax, to smooth it back over

areas where bare metal is exposed.

NOTICE

Only retouching of the wax coating

applied to the wrench flats and frame

arms is permitted, and the retouching

is to be performed only at the time of

the initial sprinkler installation.

The steel rod should be heated only to

the point at which it can begin to melt

the wax, and appropriate precautions

need to be taken when handling the

heated rod in order to prevent the

installer from being burned.

Recessed Pendent Sprinklers

The Series TY-B Recessed Pendent

Sprinklers must be installed in accor-

dance with the following instructions.

Step A. After installing the Style 10

or 40 Mounting Plate, as applicable,

over the sprinkler threads and with

pipe-thread sealant applied to the pipe

threads, hand-tighten the sprinkler into

the sprinkler tting.

Step B. Tighten the sprinkler into the

sprinkler tting using only the W-Type

7 Recessed Sprinkler Wrench (Figure

8). With reference to Figure 3 or 4, the

W-Type 7 Recessed Sprinkler Wrench

to the sprinkler wrench ats.

Step C. After the ceiling is installed or

the nish coat is applied, slide on the

Style 10 or 40 Closure over the Series

TY-B Sprinkler and push the Closure

over the Mounting Plate until its ange

contacts the ceiling.

Care and

Maintenance

The TYCO Series TY-B, 2.8, 5.6, and

8.0 K-factor, Upright and Pendent

Sprinklers must be maintained and ser-

viced in accordance with this section.

Before closing a re protection system

main control valve for maintenance

work on the re protection system

that it controls, obtain permission to

shut down the affected re protection

system from the proper authorities

and notify all personnel who may be

affected by this action.

The owner must assure that the

sprinklers are not used for hanging

any objects and that the sprinklers are

only cleaned by means of gently dust-

ing with a feather duster; otherwise,

non-operation in the event of a re or

inadvertent operation may result.

Absence of an escutcheon, which is

used to cover a clearance, may delay

the time to sprinkler operation in a re

situation.

Sprinklers which are found to be leak-

ing or exhibiting visible signs of corro-

sion must be replaced.

Automatic sprinklers must never be

painted, plated, coated, or otherwise

altered after leaving the factory.

Modied sprinklers must be replaced.

Sprinklers that have been exposed to

corrosive products of combustion, but

have not operated, should be replaced

if they cannot be completely cleaned

by wiping the sprinkler with a cloth or

by brushing it with a soft bristle brush.

Care must be exercised to avoid dam-

age to the sprinklers before, during, and

after installation. Sprinklers damaged

by dropping, striking, wrench twist/

slippage, or the like, must be replaced.

Also, replace any sprinkler that has a

cracked bulb or that has lost liquid from

its bulb. (Ref. Installation Section.)

The owner is responsible for the

inspection, testing, and maintenance of

their re protection system and devices

in compliance with this document, as

well as with the applicable standards

of the National Fire Protection Associa

-

tion (e.g., NFPA 25), in addition to the

standards of any other authorities hav-

ing jurisdiction. Contact the installing

contractor or sprinkler manufacturer

regarding any questions.

Automatic sprinklers are recommended

to be inspected, tested, and maintained

by a qualied Inspection Service in

accordance with local requirements

and/or national codes.