Installation

The Series DS-1 Dry Type Sprinklers

must be installed in accordance with

the following instructions:

NOTES

The Series DS-1 must only be installed

in fittings that meet the requirements

of the Design Criteria section.

Refer to the Design Criteria section for

other important requirements regard-

ing piping design and sealing of the

clearance space around the Sprinkler

Casing.

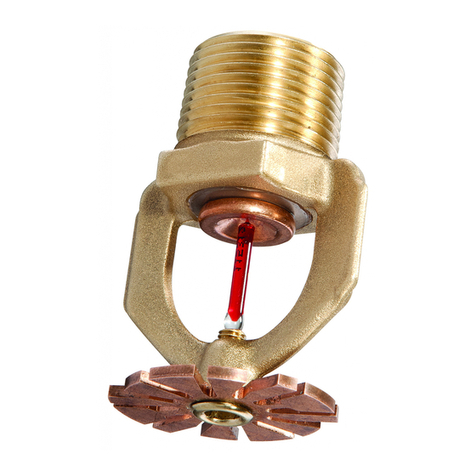

Do not install any bulb type sprinkler if

the bulb is cracked or there is a loss of

liquid from the bulb. With the sprinkler

held horizontally, a small air bubble

should be present. The diameter of the

air bubble is approximately 1/16 inch

(1,6 mm) for the 135°F/57°C rating to

1/8 inch (3,2 mm) for the 360°F/182°C

rating.

A 1 inch NPT sprinkler joint should be

obtained with a minimum to maximum

torque of 20 to 30 ft. lbs. (26,8 to 40,2

Nm). Higher levels of torque may dis-

tort the sprinkler inlet with consequent

leakage or impairment of the sprinkler.

Do not attempt to compensate for in-

sufficient adjustment in an Escutcheon

Plate by under- or over-tightening the

Sprinkler. Readjust the position of the

sprinkler fitting to suit.

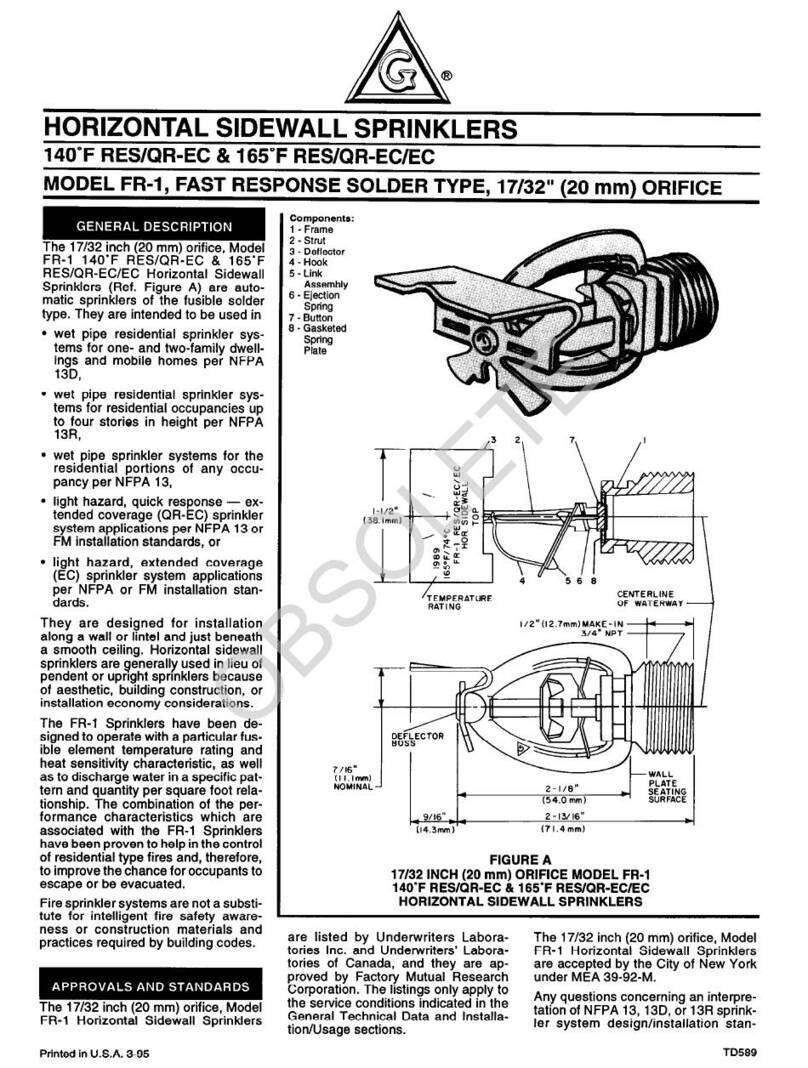

Step 1. Pendent sprinklers must be

installed only in the pendent position,

and upright sprinklers must be in-

stalled only in the upright position. The

deflector of a pendent or upright sprin-

kler is to be parallel to the ceiling.

Horizontal sidewall sprinklers are to be

installed in the horizontal position with

their centerline of waterway perpen-

dicular to the back wall and parallel to

the ceiling. The word “TOP” on the De-

flector is to face towards the ceiling.

Step 2. With pipe thread sealant ap-

plied to the inlet threads, hand tighten

the sprinkler into the sprinkler fitting.

Step 3. Wrench tighten the sprinkler by

wrenching on the Casing with a pipe

wrench whenever the casing is readily

accessible. Otherwise, use a W-Type 7

Sprinkler Wrench (Ref. Figure 2). The

wrench recess of the W-Type 7 is to be

applied to the sprinkler wrench flats

(Ref. Figure 2).

Step 4. After the ceiling/wall has been

installed/finished, slide on the outer-

piece of the Escutcheon until it comes

in contact with the ceiling/wall. Do not

lift the ceiling panel out of its normal

position.

In the case of the outer piece of the

Deep Escutcheon, hold the outer

piece in contact with the mounting

surface (ceiling), and then rotate the

inner piece approximately 1/4 turn with

respect to the outer piece, to hold the

Deep Escutcheon firmly together.

Care and

Maintenance

The Tyco®Series DS-1 Dry Type Sprin-

klers must be maintained and ser-

viced in accordance with the following

instructions:

NOTES

Absence of the outer piece of an es-

cutcheon, which is used to cover a

clearance hole, may delay the time to

sprinkler operation in a fire situation.

Before closing a fire protection sys-

tem main control valve for mainte-

nance work on the fire protection sys-

tem that it controls, permission to shut

down the affected fire protection sys-

tems must be obtained from the prop-

er authorities and all personnel who

may be affected by this action must be

notified.

A Vent Hole is provided in the Bulb

Seat (Ref. Figure 1) to indicate if the

Dry Sprinkler is remaining dry. Evi-

dence of leakage from the Vent Hole is

an indication that there may be weep-

age past the Inlet seal and that the

sprinkler needs to be removed for de-

termining the cause of leakage (e.g. an

improper installation or an ice plug).

The fire protection system control

valve must be closed and the system

drained before removing the sprinkler.

Sprinklers that are found to be leaking

or exhibiting visible signs of corrosion

must be replaced.

Automatic sprinklers must never be

painted, plated, coated, or other-

wise altered after leaving the factory.

Modified sprinklers must be replaced.

Sprinklers that have been exposed to

corrosive products of combustion, but

have not operated, should be com-

pletely cleaned by wiping the sprin-

kler with a cloth or by brushing it with a

soft bristle brush.

Care must be exercised to avoid dam-

age - before, during, and after instal-

lation. Sprinklers damaged by drop-

ping, striking, wrench twist/slippage,

or the like, must be replaced. Also, re-

place any sprinkler that has a cracked

bulb or that has lost liquid from its bulb

(Ref. Installation Section).

The owner is responsible for the in-

spection, testing, and maintenance of

their fire protection system and devices

in compliance with this document, as

well as with the applicable standards

of the National Fire Protection Associ-

ation (e.g., NFPA 25), in addition to the

standards of any other authorities hav-

ing jurisdiction. The installing contrac-

tor or sprinkler manufacturer should be

contacted relative to any questions.

Automatic sprinkler systems should be

inspected, tested, and maintained by a

qualified Inspection Service in accor-

dance with local requirements and/or

national codes.

Page 6 of 8 TFP500