Limited

Warranty

Products manufactured by Tyco Fire

Products are warranted solely to the

original Buyer for ten (10) years

against defects in material and work-

manship when paid for and properly

installed and maintained under normal

use and service. This warranty will ex-

pire ten (10) years from date of ship-

ment by Tyco Fire Products. No war-

ranty is given for products or

components manufactured by compa-

nies not affiliated by ownership with

Tyco Fire Products or for products and

components which have been subject

to misuse, improper installation, corro-

sion, or which have not been installed,

maintained, modified or repaired in ac-

cordance with applicable Standards of

the National Fire Protection Associa-

tion, and/or the standards of any other

Authorities Having Jurisdiction. Mate-

rials found by Tyco Fire Products to be

defective shall be either repaired or

replaced, at Tyco Fire Products’ sole

option. Tyco Fire Products neither as-

sumes, nor authorizes any person to

assume for it, any other obligation in

connection with the sale of products or

parts of products. Tyco Fire Products

shall not be responsible for sprinkler

system design errors or inaccurate or

incomplete information supplied by

Buyer or Buyer’s representatives.

IN NO EVENT SHALL TYCO FIRE

PRODUCTS BE LIABLE, IN CON-

TRACT, TORT, STRICT LIABILITY OR

UNDER ANY OTHER LEGAL THE-

ORY, FOR INCIDENTAL, INDIRECT,

SPECIAL OR CONSEQUENTIAL

DAMAGES, INCLUDING BUT NOT

LIMITED TO LABOR CHARGES, RE-

GARDLESS OF WHETHER TYCO

FIRE PRODUCTS WAS INFORMED

ABOUT THE POSSIBILITY OF SUCH

DAMAGES,ANDINNOEVENT

SHALL TYCO FIRE PRODUCTS’ LI-

ABILITY EXCEED AN AMOUNT

EQUAL TO THE SALES PRICE.

THE FOREGOING WARRANTY IS

MADE IN LIEU OF ANY AND ALL

OTHER WARRANTIES EXPRESS OR

IMPLIED, INCLUDING WARRANTIES

OF MERCHANTABILITY AND FIT-

NESS FOR A PARTICULAR PUR-

POSE.

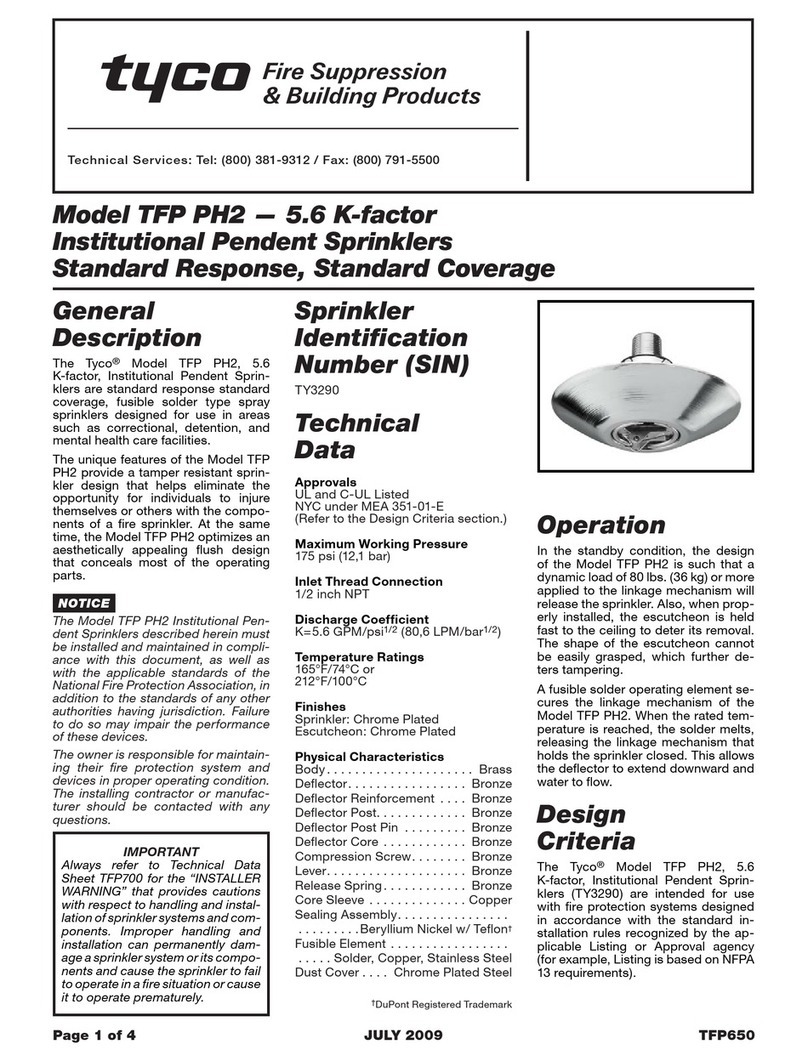

Ordering

Procedure

Contact your local distributor for avail-

ability.

Sprinkler Assemblies:

Specify: 5.6 K-factor, Chrome Plated,

(specify temperature rating), Model

TFP PH2 (TY3290) Institutional Pen-

dent Sprinkler.

140F/60C. . . . . . . . . . . . . . . . . P/N 51-104-9-140

165F/74C. . . . . . . . . . . . . . . . . P/N 51-104-9-165

212F/100C . . . . . . . . . . . . . . . P/N 51-104-9-212

Separately Ordered Escutcheons:

Specify: Style (A, B1, or C), Chrome

Plated, Institutional Escutcheons.

Style A . . . . . . . . . . . . . . . . . . . P/N 56-012-7-622

Style B1 . . . . . . . . . . . . . . . . . . P/N 56-001-7-511

Style C. . . . . . . . . . . . . . . . . . . P/N 56-001-7-513

Separately Ordered Wrenches:

Specify: Model 1509-3 Sprinkler

Wrench, P/N 56-001-5-093.

Separately Ordered Spacers For

Vertical Adjustment:

Specify: Model 1752 Spacers for use

with Style B-1 and C Institutional Es-

cutcheons, P/N 56-000-1-752.

Separately Ordered Parts For In-

stallation In Concrete With

Type A Escutcheon:

Specify: Model 1753 Recessed Cup

for use with Style A Escutcheon for

installation in concrete,

P/N 56-000-1-753.

Specify: Model 1290-8 Pipe Plug With

Shoulder for use with Style A Escutch-

eon for installation in concrete,

P/N 56-001-2-908.

Specify: Model 1754 Pipe Support for

use with Style A Escutcheon for instal-

lation in concrete, P/N 56-000-1-754.

FIGURE 4

MODEL 1509-3

SPRINKLER WRENCH

FIGURE 3

INSTALLATION IN CONCRETE WITH STYLE A ESCUTCHEON

1

2" DRIVE

ACCEPTS

TEETH

WREN

HIN

Page4of4 TFP650

TYCO FIRE PRODUCTS, 451 North Cannon Avenue, Lansdale, Pennsylvania 19446