TFP337

Page 2 of 4

Operation

When the glass bulb reaches its rated

temperature of 155°F (68°C) or 200°F

(93°C), the glass bulb bursts allowing

the sprinkler to activate and flow water.

Installation

Install the TYCO Model TY7258

Pendent Sprinkler in accordance with

this section.

General Instructions

Do not install any bulb type sprinkler

if the bulb is cracked or there is a loss

of liquid from the bulb. With the sprin-

kler held horizontal, a small air bubble

should be present. For the Model

TY7258 Sprinkler, the diameter of the

air bubble is approximately 1/16 inch

( 7, 0 m m) .

A leak tight 3/4 inch NPT sprinkler joint

should be obtained with a torque of 10

to 20 ft.-lbs. (13,4 to 26,8 Nm). Higher

levels of torque can distort the sprin-

kler inlet with consequent leakage or

impairment of the sprinkler.

Model TY7258 Pendent Sprinkler

The Model TY7258 Pendent Sprinklers

must be installed in accordance with

the following instructions:

Step 1. Apply pipe-thread sealant to

sprinkler threads.

Step 2. Hand-tighten the sprinkler into

the sprinkler fitting. Do not apply force

to the glass bulb, grasp only by wrench

flats while hand-tightening.

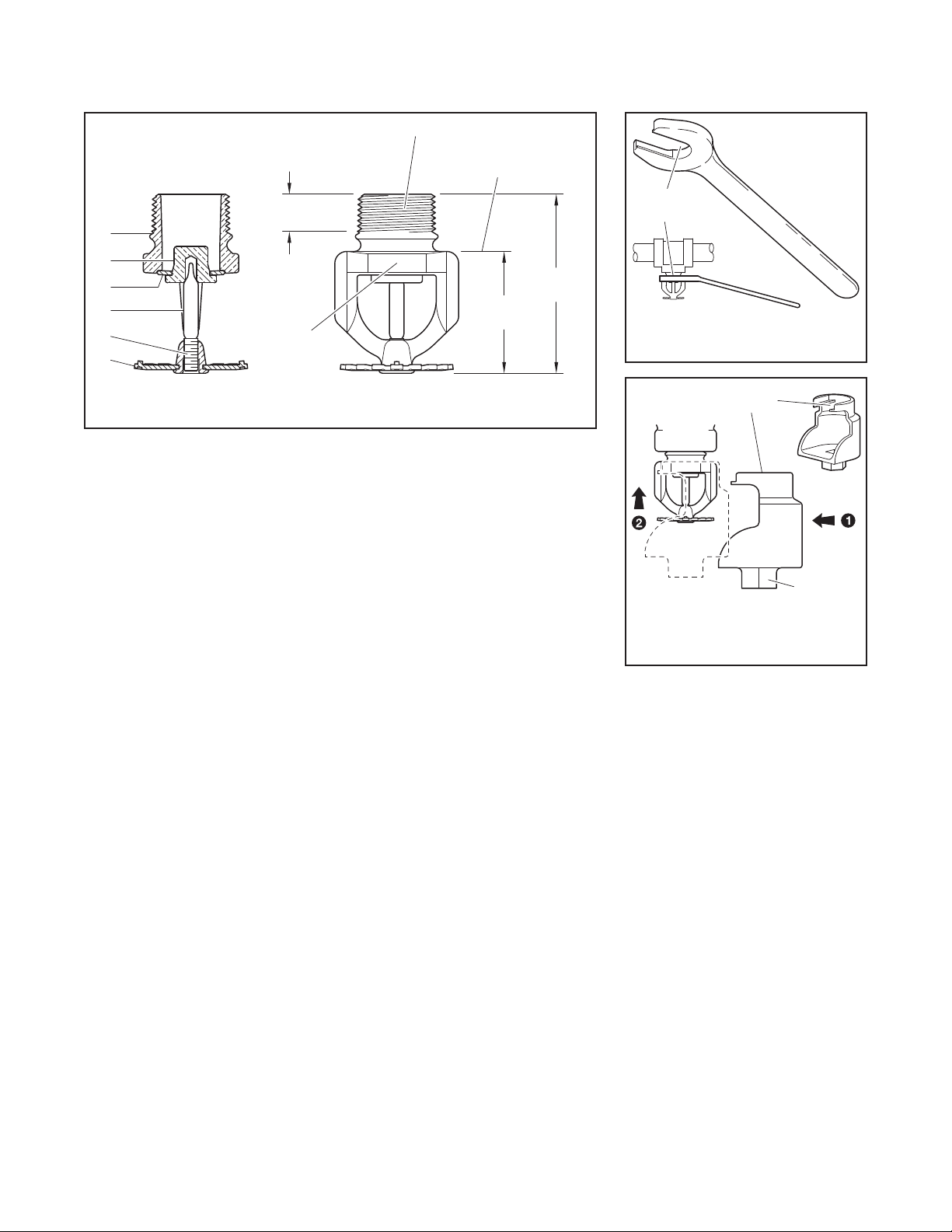

Step 3. Wrench tighten the Model

TY7258 Sprinkler using only the W-Type

8 Sprinkler Wrench (Ref. Figure 2) and

by fully engaging (seating) the wrench

on the sprinkler wrench flats.

Model TY7258 Recessed Pendent

Sprinkler with Style 30 Escutcheon

The Model TY7258 Recessed Pendent

Sprinklers must be installed in accor-

dance with the following instructions.

Step 1. After installing the Style 30

Escutcheon Mounting Plate over the

sprinkler threads, and with pipe thread

sealant applied to the pipe threads,

hand tighten the sprinkler into the

sprinkler fitting.

Step 2. Tighten the sprinkler into the

sprinkler fitting using only the W-Type

38 Sprinkler Wrench (Ref. Figure 3).

With reference to Figure 4, apply the

W-Type 38 Recessed Sprinkler Wrench

to the sprinkler wrench flats.

Step 3. After the ceiling is installed,

slide the Style 30 Escutcheon Closure

over the Model TY7258 Sprinkler and

push the closure over the mounting

plate until its flange comes in contact

with the ceiling.

Model TY7258 Pendent Sprinkler

with Style 65 Escutcheon

The pipe connected to the sprin-

kler fitting must be cut to locate the

escutcheon plate seating surface at the

proper nominal distance in front of the

wall or below the ceiling. Manufacturing

variations in the take-out of the fittings

as well as the make-in of the sprinklers

(as permitted by ANSI B1.20.1) may

require that trial cuts of the connecting

pipe be made.

Step 1. After installation of the Style

65 Escutcheon Plate over the sprinkler

threads, and with pipe thread sealant

applied to the pipe threads, hand

tighten the sprinkler into the sprinkler

fitting.

Step 2. Wrench tighten the sprinkler

into the sprinkler fitting using only the

W-Type 8 Sprinkler Wrench (Ref. Figure

2). With reference to Figure 5, apply

the W-Type 8 Sprinkler Wrench to the

sprinkler wrench flats.

Model TY7258 Pendent Sprinkler

with Style 401 Escutcheon

Step 1. After installation of the Style

401 Escutcheon Cup over the sprinkler

threads, and with pipe thread sealant

applied to the pipe threads, hand

tighten the sprinkler into the sprinkler

fitting.

Step 2. Wrench tighten the sprinkler

into the sprinkler fitting using only the

W-Type 8 Sprinkler Wrench (Ref. Figure

2). With reference to Figure 6, apply

the W-Type 8 Sprinkler Wrench to the

sprinkler wrench flats.

Step 3. After the ceiling is installed,

align the detents in the escutcheon skirt

over those in the cup and then slide

the skirt over the cup until it comes

in contact with the mounting surface.

Do not push the skirt such that it lifts

a ceiling tile out of its normal posi-

tion. Holding the skirt in contact with

the mounting surface, rotate approxi-

mately 1/8-turn relative to the cup, cre-

ating a friction fit between skirt detents

and cup surface to hold the Style 401

Escutcheon firmly together.

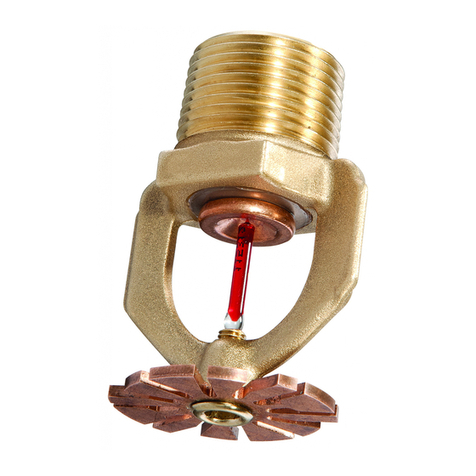

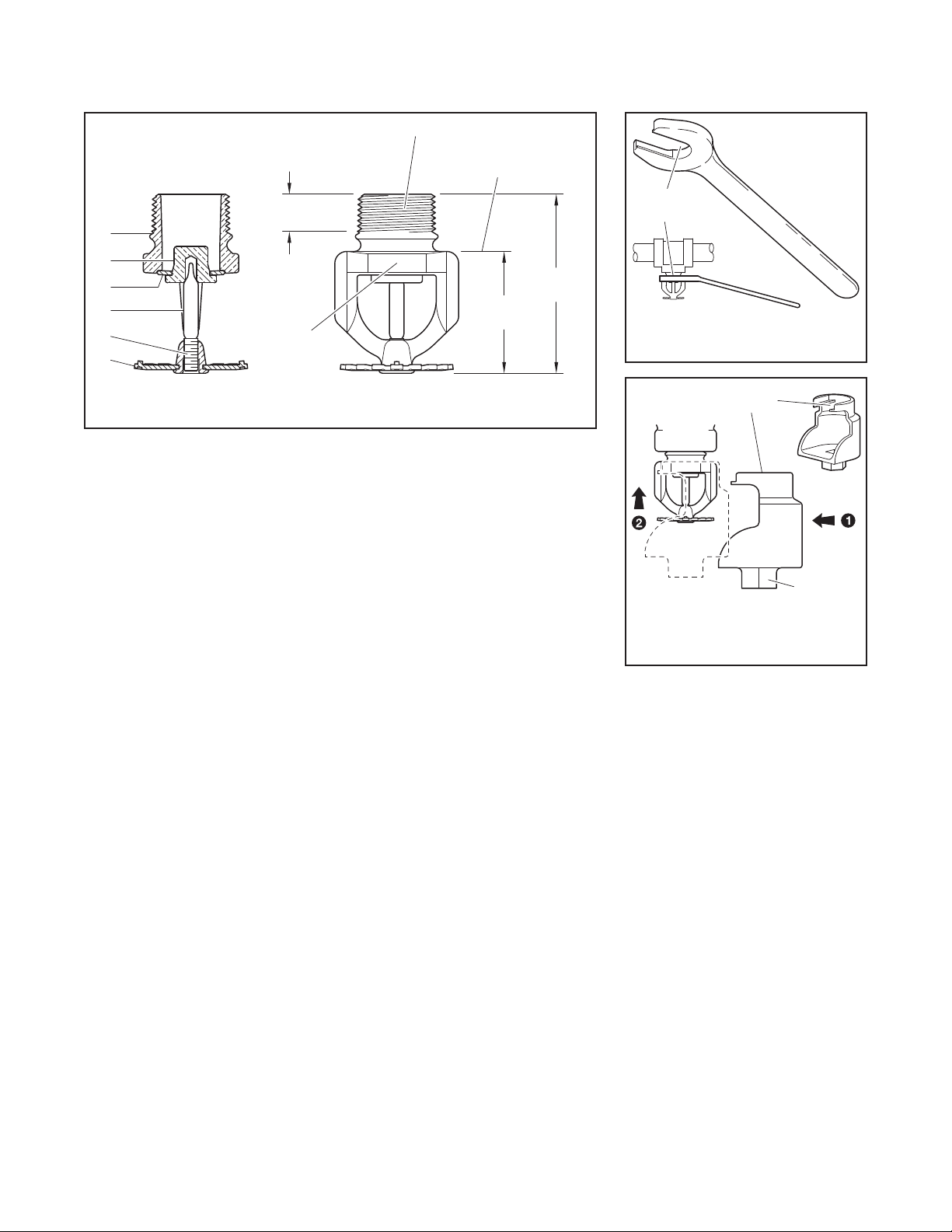

Compression Screw

Button

Deector

Sealing Assembly

-

-

-

-

5

6

2-3/8"

WRENCH

FLAT

1/2"

(12,7 mm)

NOMINAL

MAKE-IN

1-5/8"

(41,3 mm)

ESCUTCHEON

SEATING SURFACE

RECESS

WRENCH

WRENCH

RECESS

FIGURE 1

MODEL TY7258 STANDARD RESPONSE PENDENT AND

RECESSED PENDENT SPRINKLERS

FIGURE 3

W-TYPE 38 RECESSED

SPRINKLER WRENCH

FIGURE 2

W-T Y PE 8

SPRINKLER WRENCH