Installation

The TYCO RAPID RESPONSE Series

LFII Residential Flush Pendent

Sprinklers (TY2284) must be installed

in accordance with this section.

General Instructions

The Protective Cap is to remain on

the sprinkler during installation until

the ceiling installation is complete.

The Protective Cap must be removed

to place the sprinkler in service.

A leak-tight 1/2 inch NPT sprinkler

joint should be obtained by applying a

minimum-to-maximum torque of 7 to 14

ft.-lbs. (9,5 to 19,0 Nm). Higher levels

of torque can distort the sprinkler Inlet

with consequent leakage or impairment

of the sprinkler.

Do not attempt to compensate for

insufcient adjustment in the sprinkler

by under- or over-tightening the

Sprinkler/Support Cup Assembly. Re-

adjust the position of the sprinkler

tting to suit.

Each sprinkler must be inspected

before installation. Do not use any

sprinkler that exhibits any deformations

or cracks, including cracks on the

protective cap.

Step 1. The sprinkler must be installed

only in the pendent position and with

the sprinkler waterway centerline

perpendicular to the mounting surface.

Step 2. Install the sprinkler tting so

that the distance from the face of the

tting to the mounting surface will be

nominally 29/32 inches (23,0 mm) as

shown in Figure 1A.

Step 3. With pipe thread sealant

applied to the pipe threads, hand-

tighten the sprinkler into the sprinkler

tting.

Step 4. Tighten the sprinkler using only

the Sprinkler Socket or Wrench

& Socket Combination (Figure 2).

The wrench recess of the socket is to

be applied to the sprinkler wrenching

area (Figure 1A).

Step 5. Use the “ceiling level tolerance

limit” indicator on the Protective

Cap to check for proper installation

height. Relocate the sprinkler tting as

necessary. If desired, the Protective

Cap may also be used to locate the

center of the clearance hole by gently

pushing the ceiling material against the

center point of the Cap.

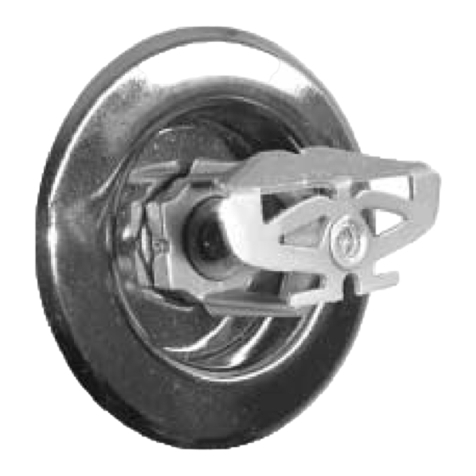

Step 6. After the ceiling has been

completed with the 2 inch (50

mm diameter clearance hole, use

the Protective Cap Removal Tool

(Figure 3) to remove the Protective

Cap and then push on the Escutcheon

until its ange just comes in contact

with the ceiling. Do not continue

to push the Escutcheon such that

it lifts a ceiling panel out of its

normal position. If the Escutcheon

cannot be engaged with the sprinkler,

or the Escutcheon cannot be engaged

sufciently to contact the ceiling,

relocate the sprinkler fitting as

necessary.

Care and

Maintenance

The TYCO RAPID RESPONSE Series

LFII Residential Flush Pendent

Sprinklers (TY2284) must be main-

tained and serviced in accordance with

this section.

Before closing a re protection system

main control valve for maintenance

work on the re protection system

that it controls, obtain permission to

shut down the affected re protection

systems from the proper authorities

and notify all personnel who may be

affected by this action.

Absence of the outer piece of an

escutcheon, which is used to cover

a clearance hole, can delay sprinkler

operation in a re situation.

The owner must assure that the sprin-

klers are not used for hanging any

objects and that the sprinklers are only

cleaned by means of gently dusting

with a feather duster; otherwise, non-

operation in the event of a re or inad-

vertent operation may result.

Sprinklers which are found to be

leaking or exhibiting visible signs of

corrosion must be replaced.

Automatic sprinklers must never be

painted, plated, coated, or otherwise

altered after leaving the factory.

Modied or overheated sprinklers must

be replaced.

Care must be exercised to avoid

damage to the sprinklers - before,

during, and after installation. Sprinklers

damaged by dropping, striking, wrench

twist/slippage, or the like, must be

replaced.

The owner is responsible for the

inspection, testing, and maintenance of

their re protection system and devices

in compliance with this document, as

well as with the applicable standards of

the National Fire Protection Association

(e.g., NFPA 25), in addition to the

standards of any authorities having

jurisdiction. Contact the installing

contractor or sprinkler manufacturer

regarding any questions.

Automatic sprinkler systems are

recommended to be inspected,

tested, and maintained by a qualied

Inspection Service in accordance with

local requirements and/or national

codes.

Ordering

Procedure

Contact your local distributor for

availability. When placing an order,

indicate the full product name and Part

Number (P/N).

Sprinkler Assembly

Specify: Series LFII (TY2284), K=4.2,

Residential Flush Pendent Sprinkler

without Escutcheon and having a

(specify) nish, P/N (specify).

Antique Brass..............P/N 51-123 -1-162

Signal White (RAL9003)......P/N 51-123-4-162

Jet Black (RAL9005) ........P/N 51-123-6-162

Chrome Plated .............P/N 51-123-9 -162

Escutcheon

Specify: Escutcheon for Series LFII

(TY2284), K=4.2, Residential Flush

Pendent Sprinkler with (specify) nish,

P/N (specify).

Antique Brass............. P/N 56-123-1- 0 01

Signal White (RAL9003).....P/N 56-123-4-001

Jet Black (RAL9005) .......P/N 56-123-6-001

Chrome..................P/N 56 -123-9-001

Accessories

Specify: Wrench and Socket for

Series LFII (TY2284) Residential Flush

Pendent Sprinkler, P/N 56-000-4-948.

Specify: Socket for Series LFII

(TY2284) Residential Flush Pendent

Sprinkler, P/N 56-000-4-947.

Specify: Protective Cap Removal

Tool for Series LFII Residential Flush

Pendent Sprinkler (TY2284), P/N

56-000-4-300.

TFP420

Page 5 of 6