TFP661

Page 2 of 4

areas where bare metal is exposed.

NOTES: Only retouching of the wax

coating applied to the wrench flats

and frame arms is permitted, and

the retouching is to be performed

only at the time of the initial sprinkler

installation.

The steel rod should be heated only to

the point at which it can begin to melt

the wax, and appropriate precautions

need to be taken, when handling the

heated rod, in order to prevent the

installer from being burned.

If attempts to retouch the wax coating

with complete coverage are unsuccess-

ful, additional wax can be ordered in the

form of a wax stick (the end of which

is color coded). Only the correct color

coded wax is to be used, and retouch-

ing of wrench ats and frame arms

is only permitted at the time of initial

sprinkler installation. With the steel rod

Design

Criteria

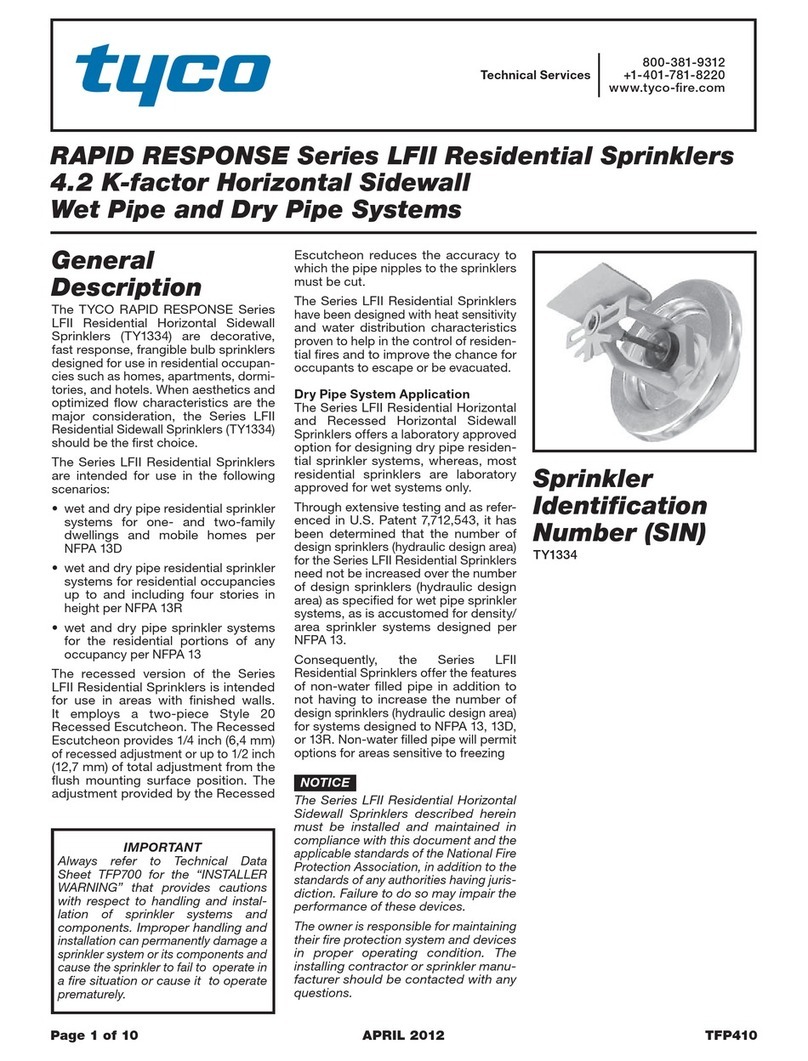

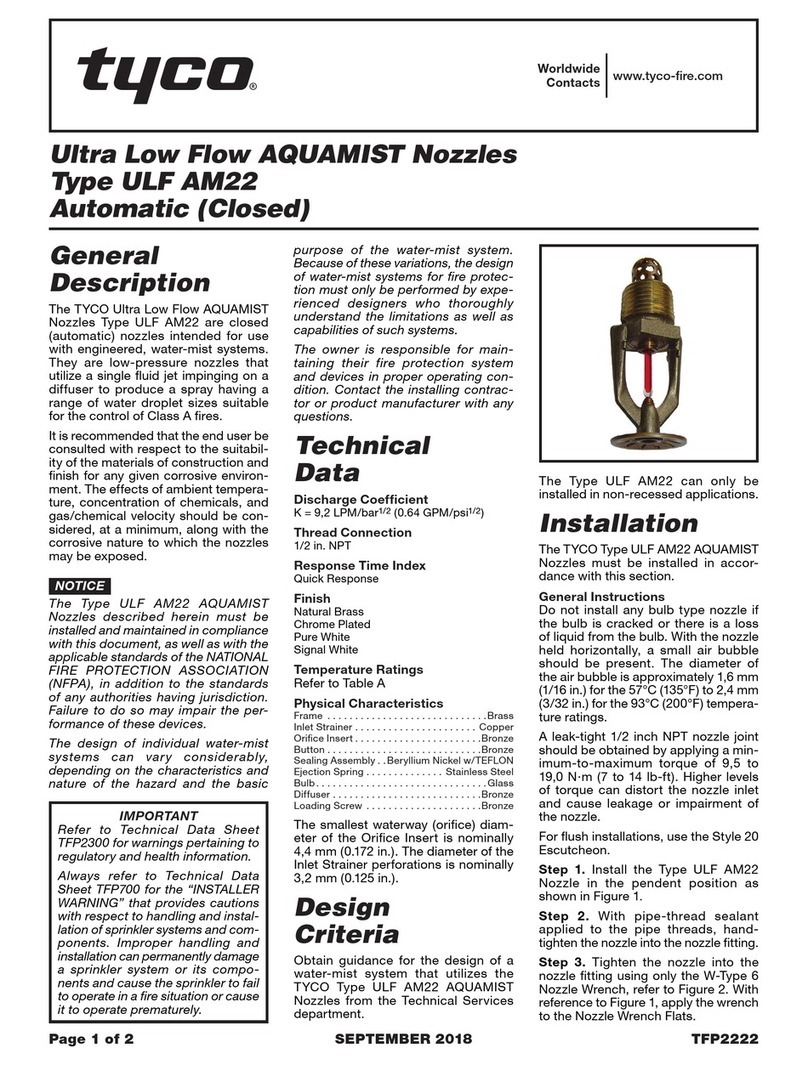

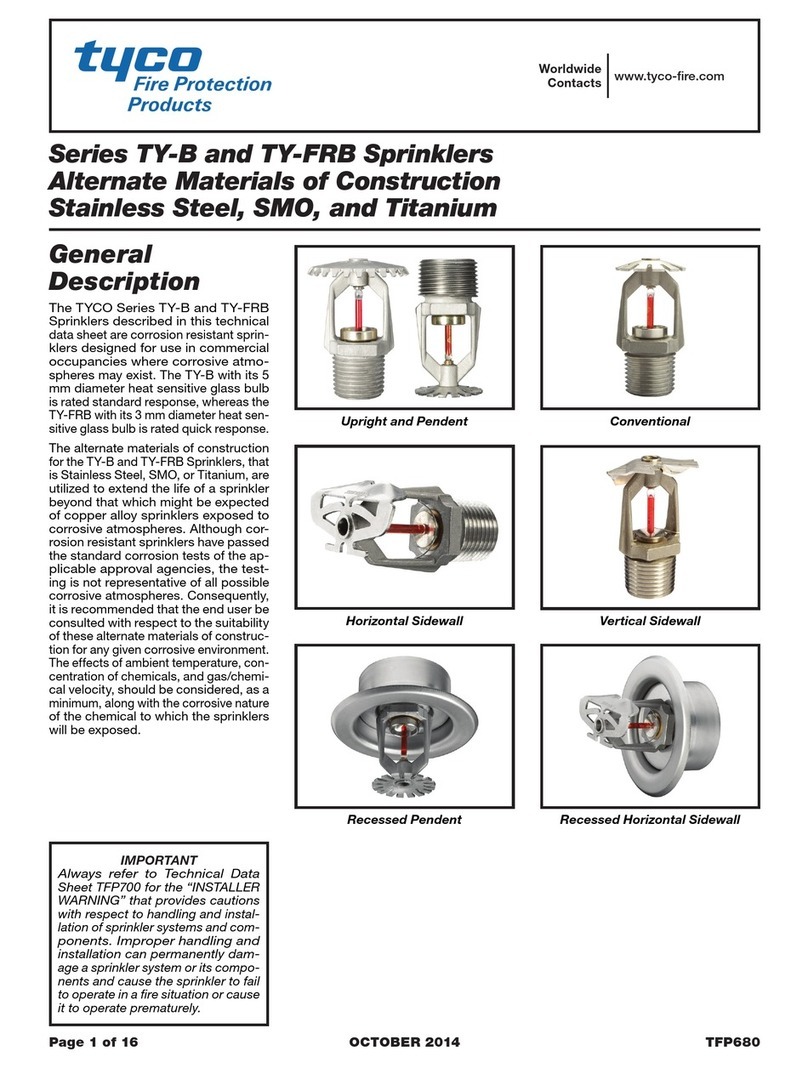

The Series TY-B Conventional Sprin-

klers are intended for re protection

systems designed in accordance

with the standard installation rules

recognized by the applicable Listing

or Approval agency (e.g., UL Listing is

based on NFPA 13 requirements). The

Series TY-B Conventional Sprinklers

are only for non-recessed applications.

Installation

The Series TY-B Sprinklers must

be installed in accordance with this

section.

General Instructions

Do not install any bulb type sprinkler if

the bulb is cracked or there is a loss of

liquid from the bulb. With the sprinkler

held horizontally, a small air bubble

should be present. The diameter of the

air bubble is approximately 1/16 inch

(1,6 mm) for the 135°F (57°C) to 3/32

inch (2,4 mm) for the 360°F (182°C)

temperature ratings.

A leak tight 1/2 inch NPT sprinkler joint

should be obtained with a torque of 7

to 14 ft.-lbs. (9,5 to 19,0 Nm). A leak

tight 3/4 inch NPT sprinkler joint should

be obtained with a torque of 10 to 20

ft.-lbs (13,4 to 26,8 Nm). Higher levels

of torque may distort the sprinkler inlet

and cause leakage or impairment of the

sprinkler.

Step 1. With pipe thread sealant

applied to the pipe threads, hand

tighten the sprinkler into the sprinkler

tting.

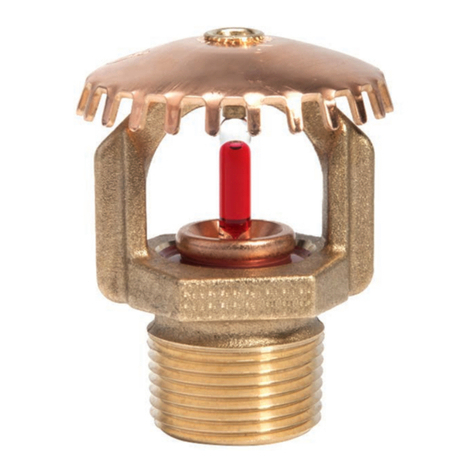

Step 2. Tighten the sprinkler into the

sprinkler tting using only the W-Type

6 Sprinkler Wrench (Ref. Figure 2),

except that an 8 or 10 inch adjustable

Crescent wrench is to be used for wax

coated sprinklers. With reference to

Figure 1, the W-Type 6 Sprinkler Wrench

or the Crescent wrench, as applicable,

is to be applied to the wrench ats.

When installing wax coated sprinklers

with the adjustable Crescent wrench,

additional care needs to be exercised

to prevent damage to the wax coating

on the sprinkler wrench ats or frame

arms and, consequently, exposure of

bare metal to the corrosive environ-

ment. The jaws of the wrench should be

opened sufciently wide to pass over

the wrench ats without damaging the

wax coating. Before wrench tightening

the sprinkler, the jaws of the wrench

are to be adjusted to just contact the

sprinkler wrenching anges. After

wrench tightening the sprinkler, loosen

the wrench jaws before removing the

wrench.

After installation, the sprinkler wrench

ats and frame arms must be inspected

and the wax coating retouched

(repaired) whenever the coating has

been damaged and bare metal is

exposed. The wax coating on the

wrench ats can be retouched by gen-

tly applying a heated 1/8 inch diameter

steel rod to the areas of wax that have

been damaged, to smooth it back over

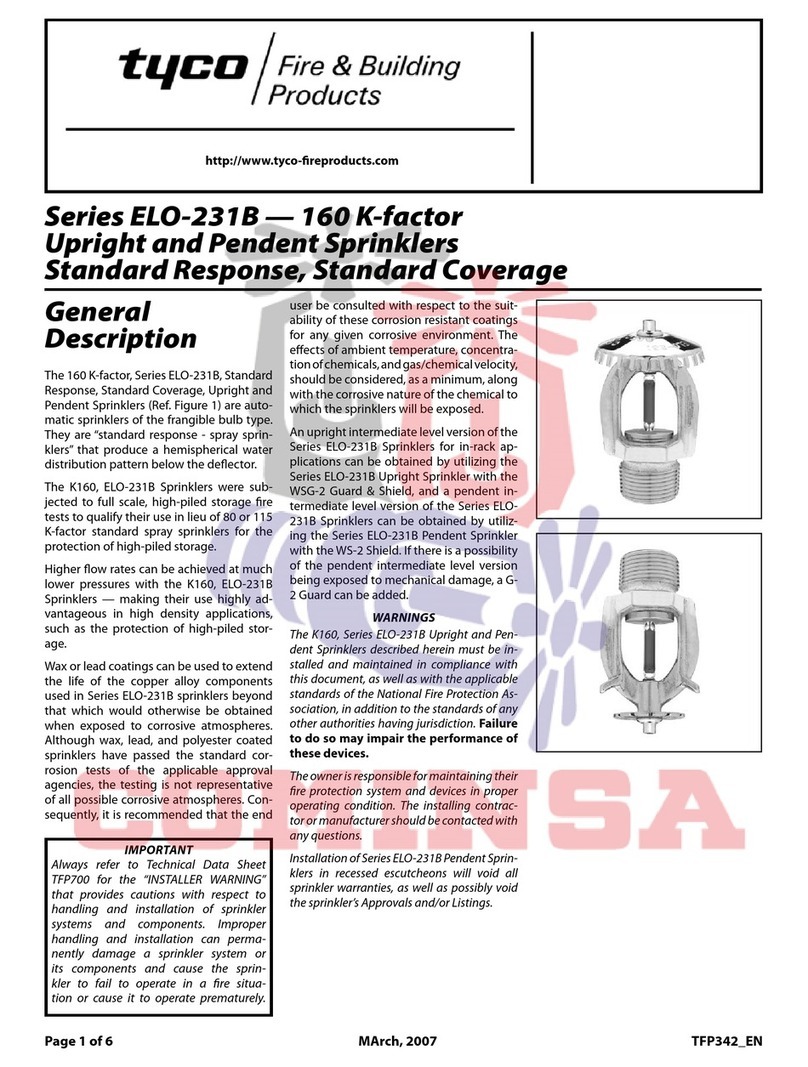

*

****

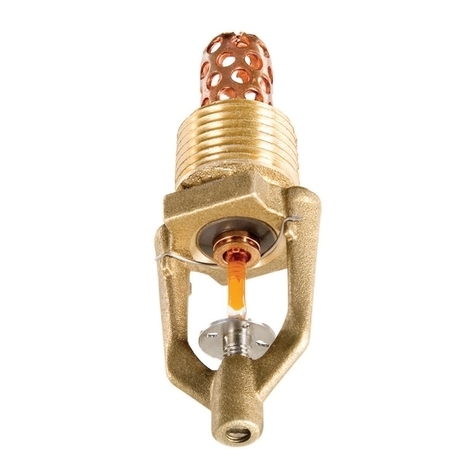

*

SHOWN

SHOWN

CROSS SECTION

CROSS SECTION

7/16" (11,1 mm)

NOMINAL

MAKE-IN

ESCUTCHEON

PLATE SEATING

SURFACE

ESCUTCHEON

PLATE SEATING

SURFACE

Pipe thread connections per

ISO 7-1 can be provided on

special request.

indicated on Deector

or adjacent to orice

seat on Frame.

WRENCH

FLATS

WRENCH

FLATS

Sealing

Assembly

Compression

Screw

1/2"

NPT

2-3/16"

1-1/2"

(38,1 mm)

1-1/2"

(38,1 mm)

2

4

5

6

1

33

1

2

5

4

6

7

1

2

Bulb

Button

Frame

-

-4-Ejection

Spring

7-

3-

5-

Deector6 -

3/4"

NPT

1/2" (12,7 mm)

NOMINAL

MAKE-IN

2-1/4"

(57,2 mm)

WRENCH RECESS

1/2" NPT MODELS)

WRENCH RECESS

(END "B" USED FOR

FIGURE 1

SERIES TY-B 5.6 K-FACTOR (TY3651) AND 8.0 K-FACTOR (TY4651)

STANDARD RESPONSE CONVENTIONAL SPRINKLERS

FIGURE 2

W-TYPE 6

SPRINKLER WRENCH