TFP501

Page 3 of 6

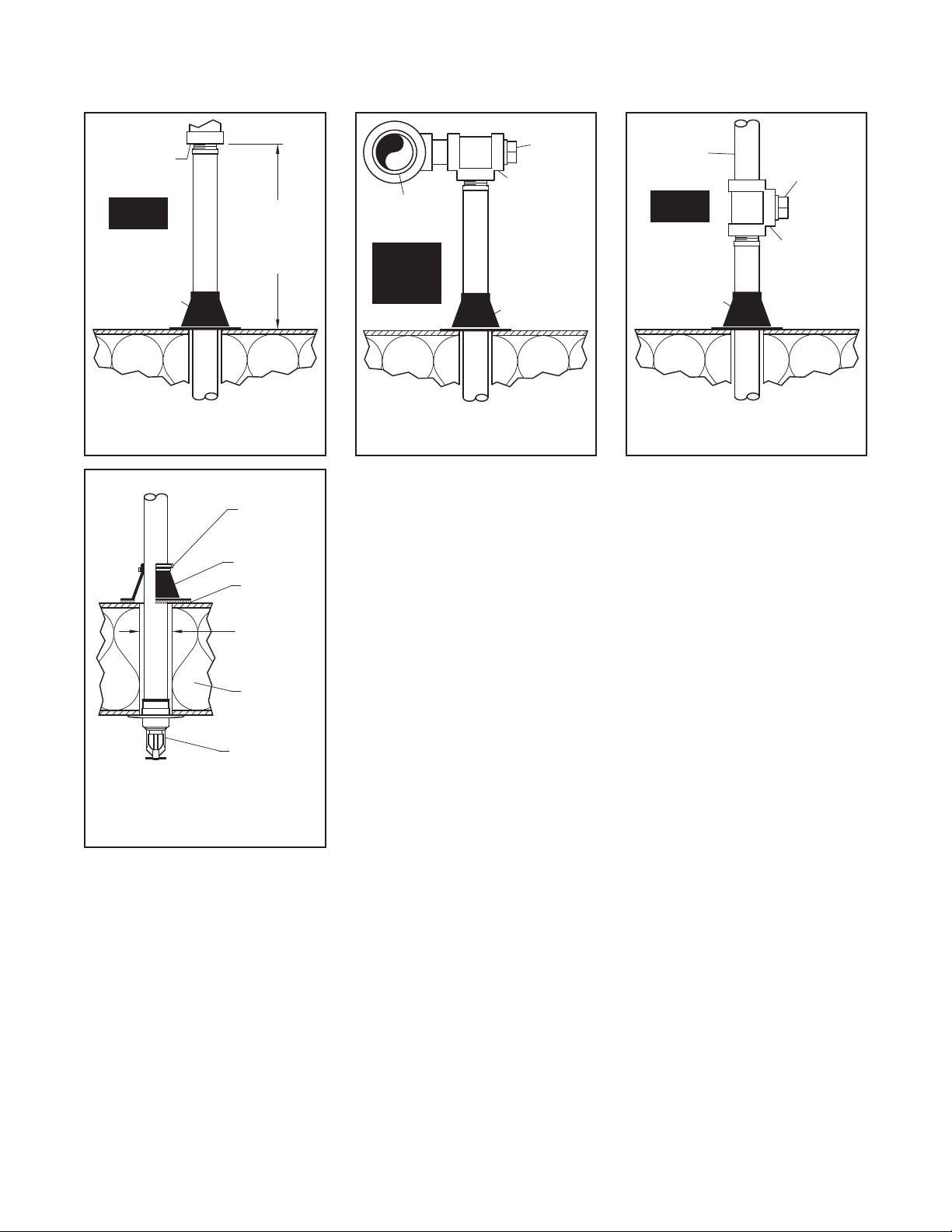

subject to freezing temperatures, use

Table A to determine a sprinkler’s

appropriate exposed barrel length to

prevent water from freezing in the con-

necting pipes due to conduction. The

exposed barrel length measurement

must be taken from the face of the

sprinkler fitting to the surface of the

structure or insulation that is exposed

to the heated area. Refer to Figure 5 for

an example.

For protected area temperatures

between those given above, the

minimum recommended length from

the face of the fitting to the outside of

the protected area may be determined

by interpolating between the indicated

values.

Clearance Space

In accordance with VdS CEA 4001,

when connecting an area subject to

freezing and an area containing a

wet pipe sprinkler system, the clear-

ance space around the sprinkler

barrel of dry-type sprinklers must be

sealed. Due to temperature differences

between two areas, the potential for

the formation of condensation in the

sprinkler and subsequent ice build-up

is increased. If this condensation is not

controlled, ice build-up can occur that

might damage the dry-type sprinkler

and/or prevent proper operation in a

re situation.

Use of the Model DSB-2 Dry Sprinkler

Boot, described in technical data sheet

TFP591 and shown in Figures 8, can

provide the recommended seal.

Installation

TYCO Series DS-1 5.6K Pendent, Stan-

dard Response, Standard Coverage

Dry-Type Sprinklers must be installed

in accordance with this section.

General Instructions

Series DS-1 Dry-Type Sprinklers must

only be installed in fittings that meet

the requirements of the Design Crite-

ria section. Refer to the Design Criteria

section for other important require-

ments regarding piping design and

sealing of the clearance space around

the Sprinkler Casing.

Do not install any bulb-type sprinkler

if the bulb is cracked or there is a loss

of liquid from the bulb. With the sprin-

kler held horizontally, a small air bubble

should be present. The diameter of the

air bubble is approximately 1/16 in.

(1,6 mm) for the 135°F (57°C) rating to

1/8 in. (3,2 mm) for the 360°F (182°C)

rating.

Obtain a leak-tight ISO 7-R1 sprinkler

joint by applying a minimum-to-maxi-

mum torque of 20 to 30 lb-ft (26,8 to

40,2 N·m). Higher levels of torque may

distort the sprinkler Inlet with conse-

quent leakage or impairment of the

sprinkler.

Do not attempt to compensate for

insufficient adjustment in an Escutch-

eon Plate by under or over-tightening

the Sprinkler. Re-adjust the position of

the sprinkler fitting to suit.

Note: Install pendent sprinklers only in

the pendent position. The deflector of

a pendent sprinkler is to be parallel to

the ceiling.

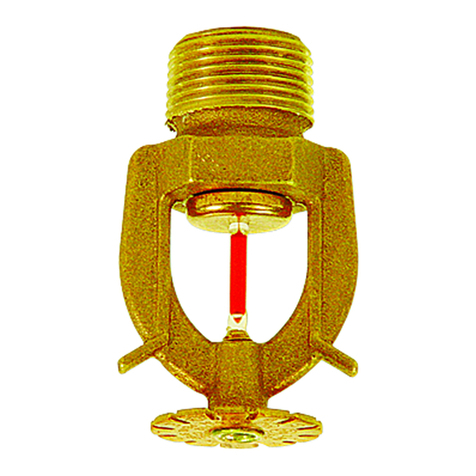

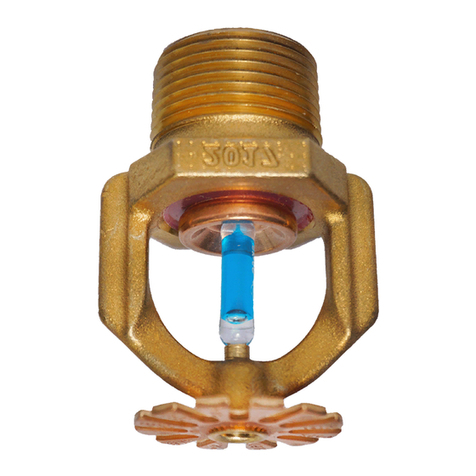

Step 1. With a non-hardening pipe-

thread sealant such as TEFLON applied

to the inlet threads, hand-tighten the

sprinkler into the sprinkler fitting.

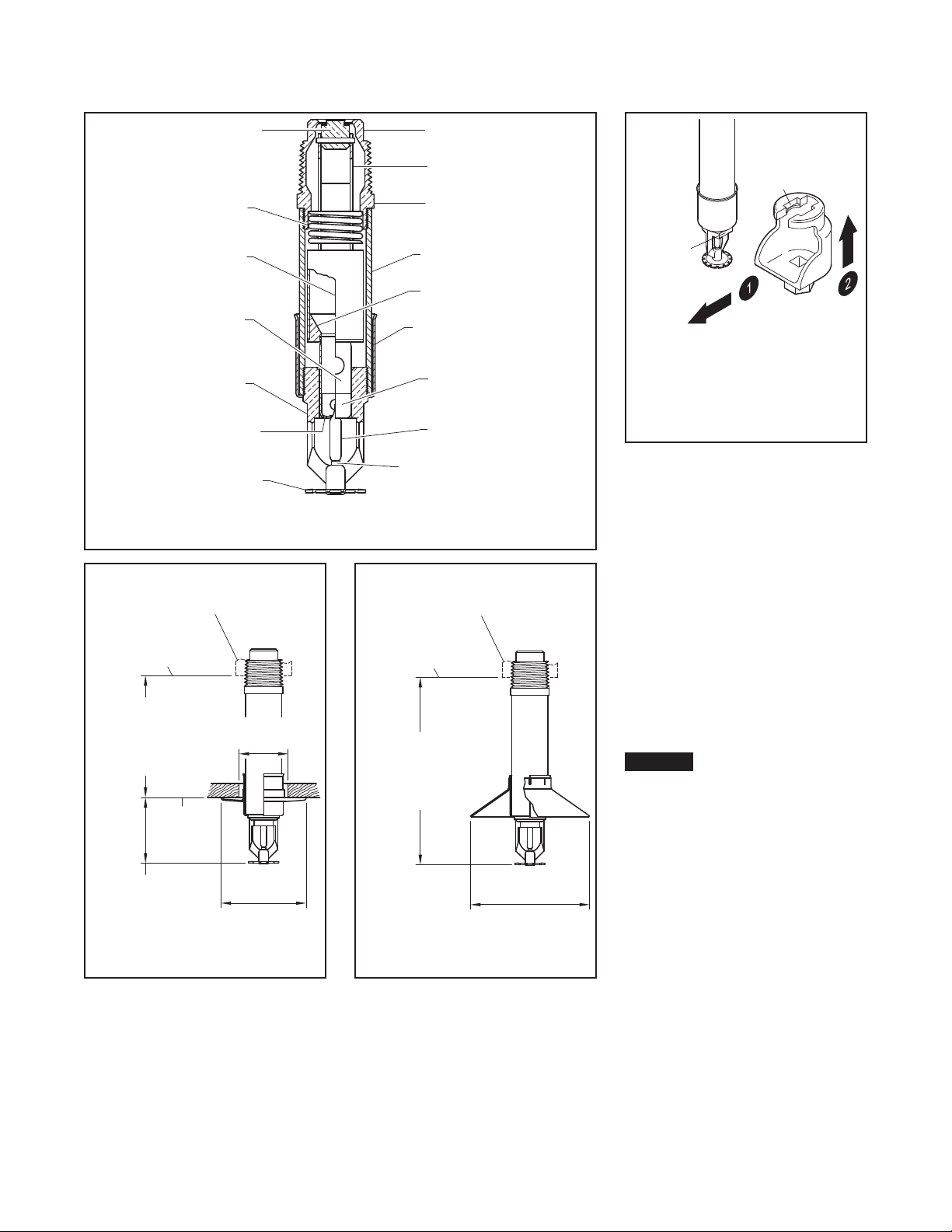

Step 2. Wrench-tighten the sprinkler

using either:

• a pipe wrench on the Inlet Band or

the Casing (See Figure 1)

• the W-Type 7 Sprinkler Wrench on

the Wrench Flat (See Figure 2)

Apply the wrench recess of the W-Type

7 Sprinkler Wrench to the wrench flat.

Note: If sprinkler removal becomes

necessary, remove the sprinkler using

the same wrenching method noted

above. Sprinkler removal is easier when

a non-hardening sealant was used

and torque guidelines were followed.

After removal, inspect the sprinkler for

damage.

Step 3. After installing the ceiling and

applying a ceiling finish, slide on the

outer piece of the escutcheon until

it comes in contact with the ceiling.

Do not lift the ceiling panel out of its

normal position.

To install the baffle plate properly, push

on until the top edge reaches the flared

edge of the escutcheon.

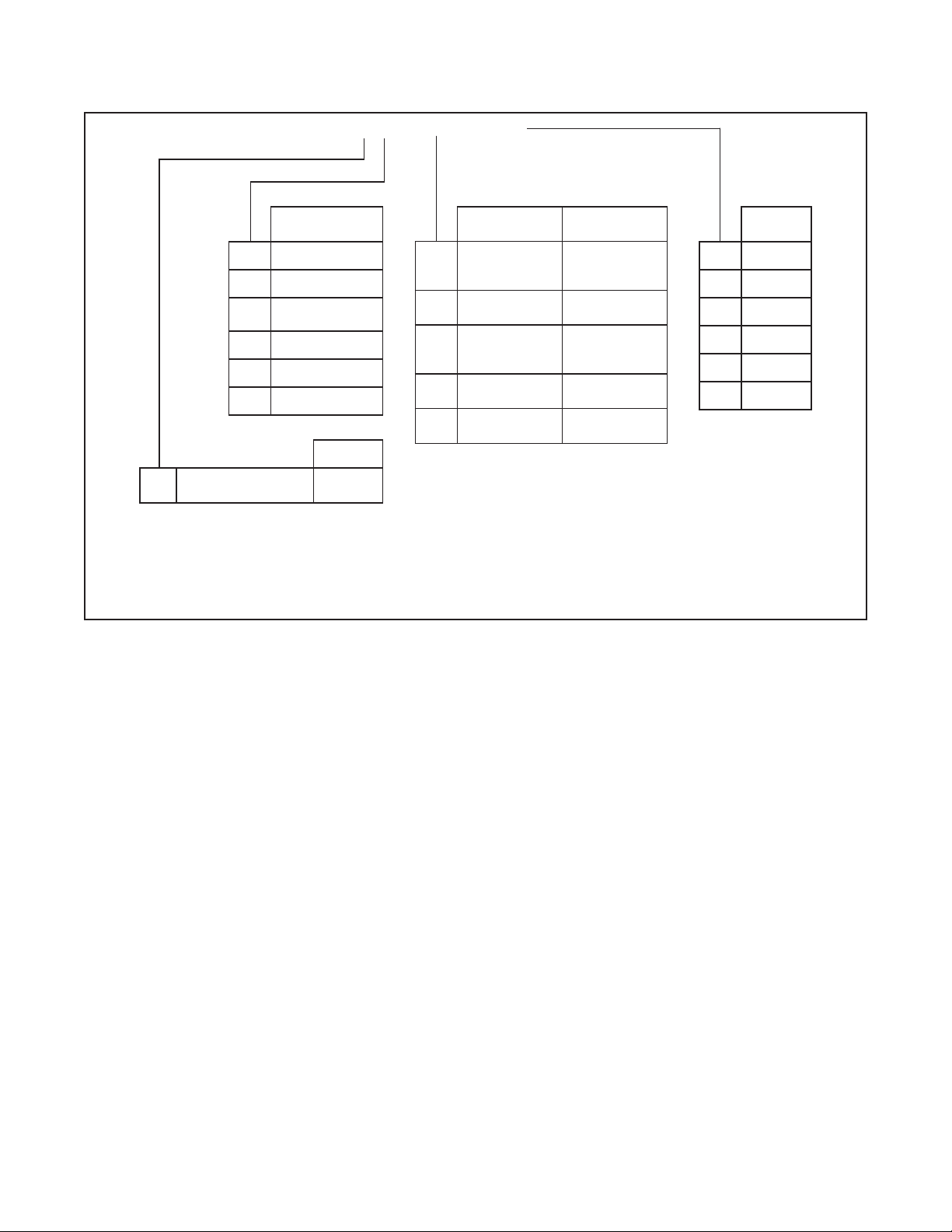

Ambient Temperature

Exposed to

Discharge End of Sprinkler

Temperatures for Heated Area(1)

40°F

(4°C) 50°F

(10°C) 60°F

(16°C)

Minimum Exposed Barrel Length(2),

Inches

(mm)

40°F

(4°C) 000

30°F

(-1°C) 000

20°F

(-7°C)

4

(100) 0 0

10°F

(-12°C)

8

(200)

1

(25) 0

0°F

(-18°C)

12

(305)

3

(75) 0

-10°F

(-23°C)

14

(355)

4

(100)

1

(25)

-20°F

(-29°C)

14

(355)

6

(150)

3

(75)

-30°F

(-34°C)

16

(405)

8

(200)

4

(100)

-40°F

(-40°C)

18

(455)

8

(200)

4

(100)

-50°F

(-46°C)

20

(510)

10

(255)

6

(150)

-60°F

(-51°C)

20

(510)

10

(255)

6

(150)

Notes:

1. For protected area temperatures that occur between values listed above, use the next cooler temperature.

2. These lengths are inclusive of wind velocities up to 30 mph (18,6 kph).

TABLE A

EXPOSED SPRINKLER BARRELS IN WET PIPE SYSTEMS

MINIMUM RECOMMENDED LENGTHS