Model TY-QRF – 5.6 K-factor

Flush Pendent Sprinkler

Quick Response, Standard Coverage

Page 1 of 4 FEBRUARY 2015 TFP190

IMPORTANT

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cautions

with respect to handling and instal-

lation of sprinkler systems and com-

ponents. Improper handling and

installation can permanently damage

a sprinkler system or its compo-

nents and cause the sprinkler to fail

to operate in a fire situation or cause

it to operate prematurely.

Sprinkler

Identification

Number (SIN)

TY3261

Technical

Data

Approvals

UL and ULC Listed

Maximum Working Pressure

175 psi (12,1 bar)

Discharge Coefficient

K=5.6 gpm/psi1/2 (80,6 lpm/bar1/2)

Temperature Rating

162°F (72°C)

Vertical Adjustment

3/8 inch (9,5 mm)

Finishes

Sprinkler and Escutcheon:

Signal White, Jet Black, or Chrome

Physical Characteristics

Body. . . . . . . . . . . . . . . . . . . Copper Alloy

Deflector. . . . . . . . . . . . . . . . . . . . . Copper

Valve Cap . . . . . . . . . . . . . . . Copper Alloy

Orifice Seal. . . . . . . . . . . . . . . . . . . . .PTFE

Heat Collectors . . . . . . . . . . . . . . . Copper

Operation

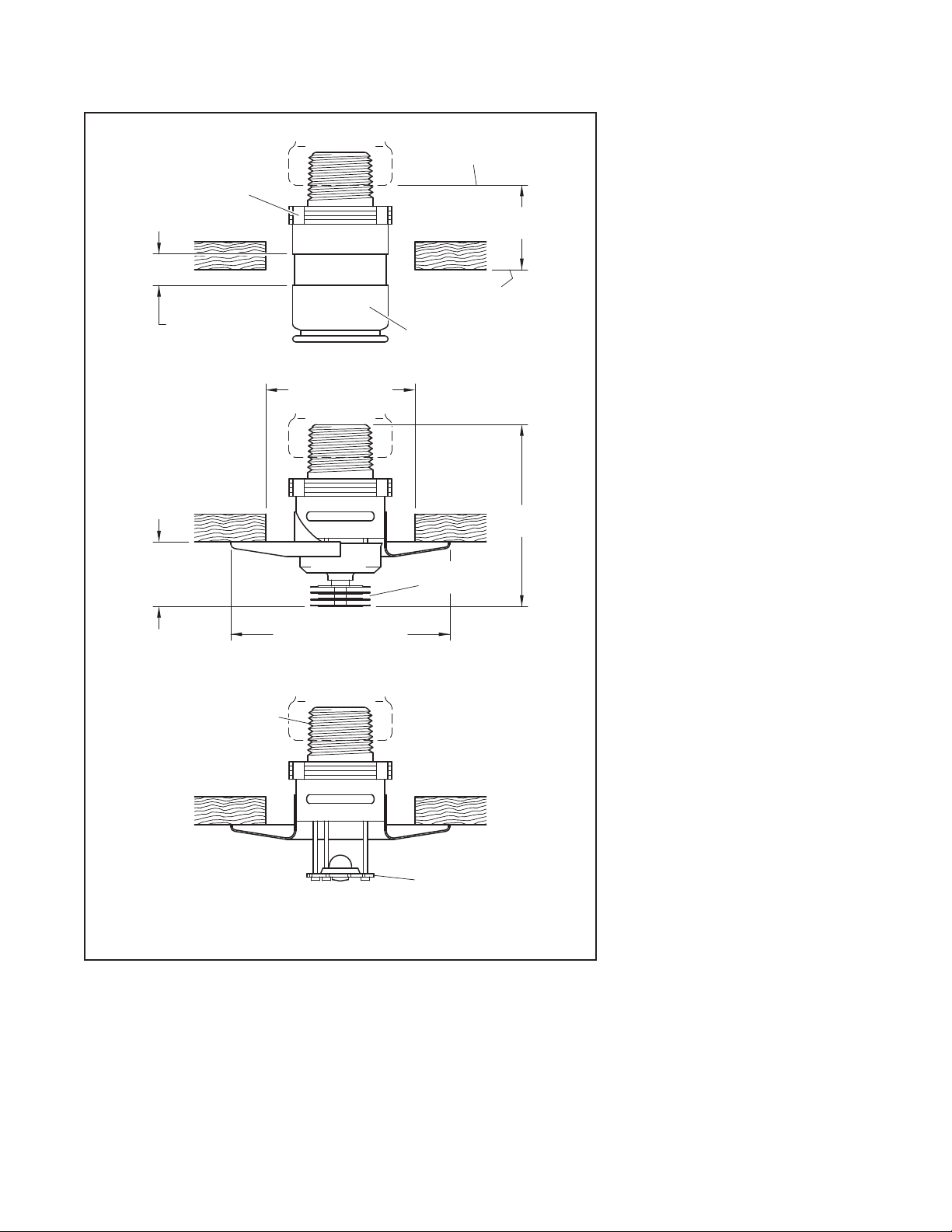

The sprinkler assembly contains a

small fusible solder element. When

exposed to sufficient heat from a fire,

the solder melts and enables the inter-

nal components of the sprinkler to fall

away. At this point the sprinkler acti-

vates with the deflector dropping into

its operated position (Ref. Figure 1C),

permitting water to flow.

General

Description

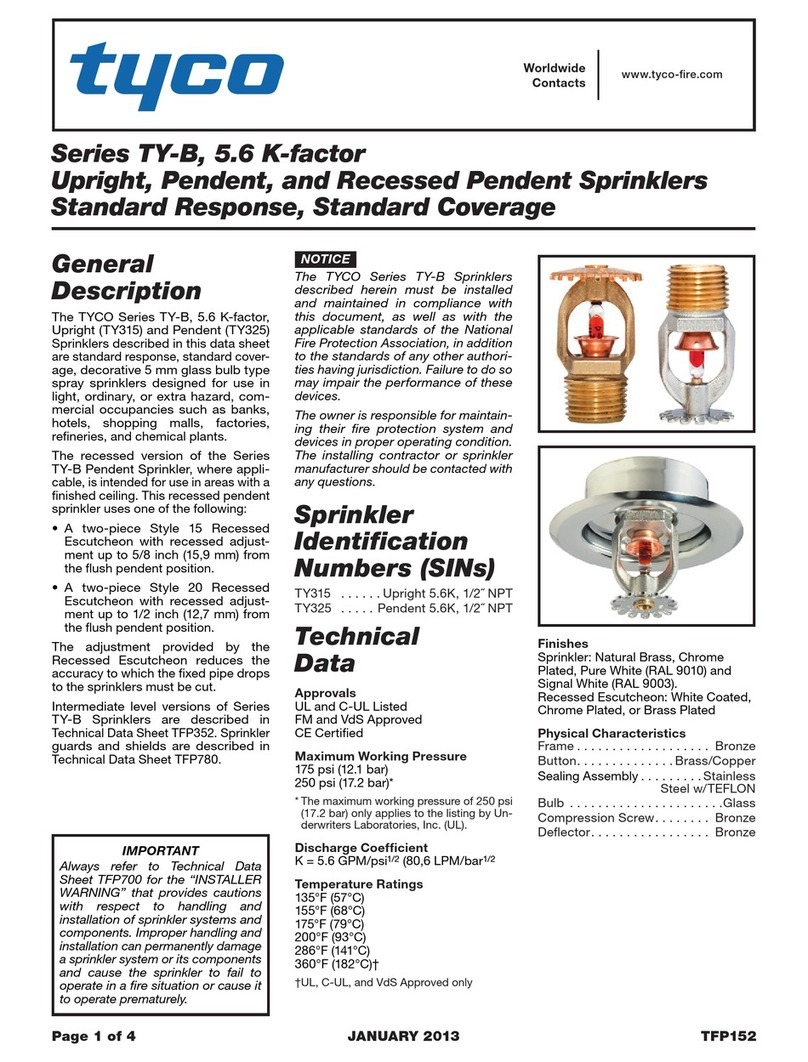

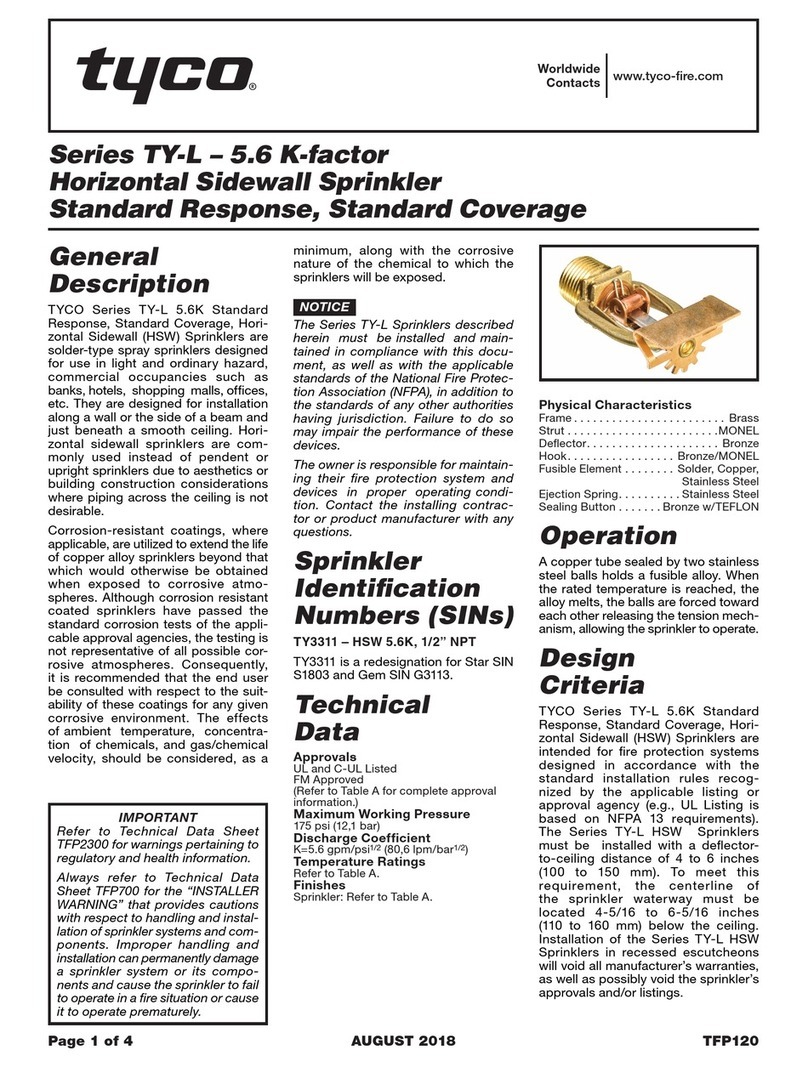

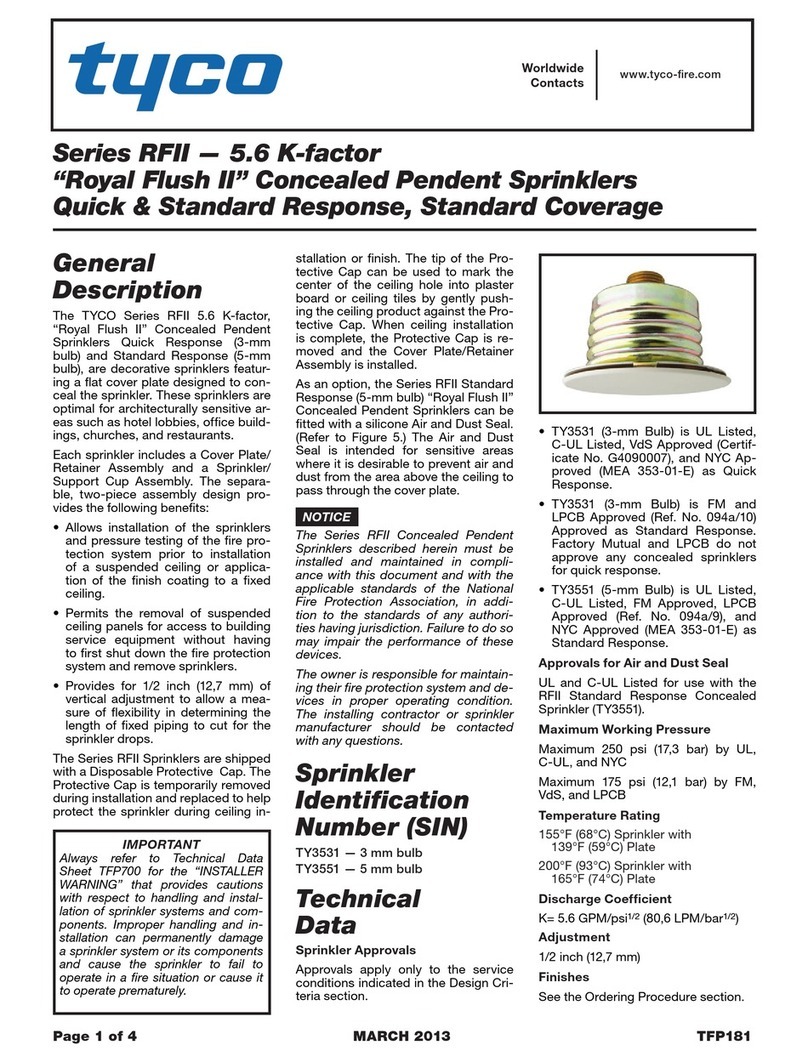

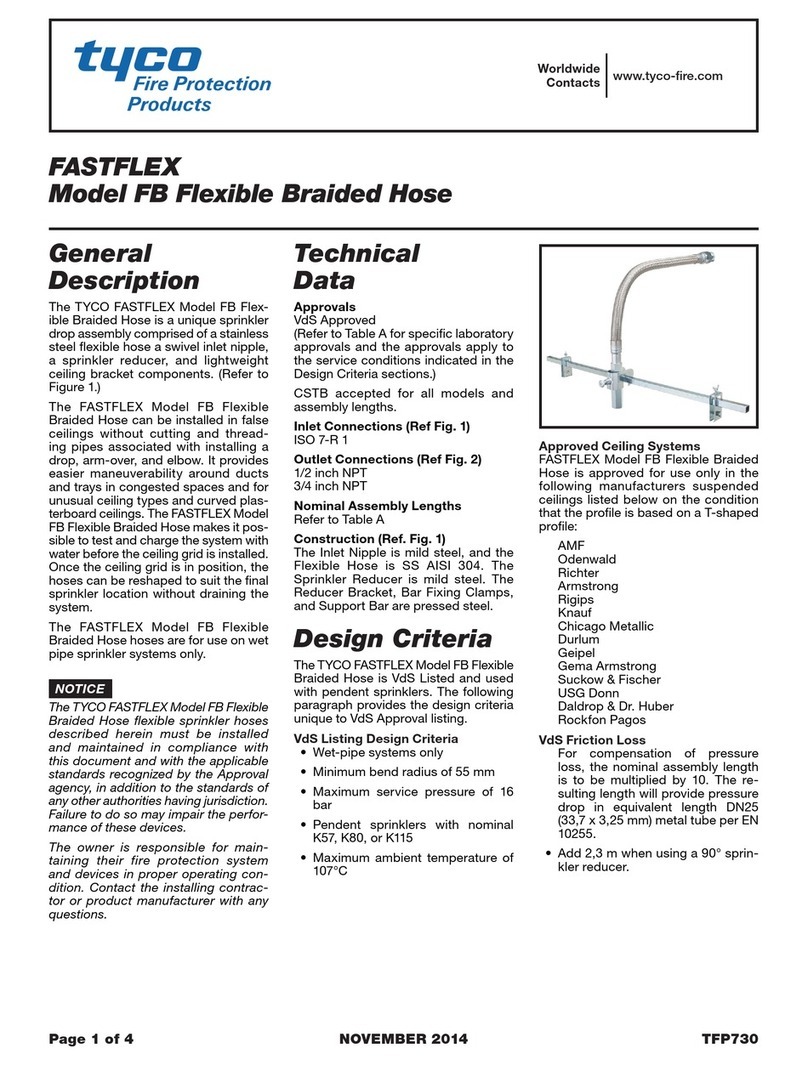

TYCO Model TY-QRF 5.6K Quick

Response, Standard Coverage, Flush

Pendent Sprinklers are decorative,

fusible solder-type sprinklers. They are

designed for use in commercial light

and ordinary hazard occupancies such

as offices and restaurants. When aes-

thetics is the major consideration, the

TY-QRF should be your first choice.

The TY-QRF features a separa-

ble escutcheon providing 3/8 inch

(9,5 mm) vertical adjustment. This

adjustment reduces the accuracy

to which the fixed pipe drops to the

sprinklers must be cut to help assure

a perfect fit installation.

NOTICE

The Model TY-QRF Flush Pendent

Sprinklers described herein must be

installed and maintained in compli-

ance with this document, as well as

with the applicable standards of the

National Fire Protection Associa-

tion, in addition to the standards of

any authorities having jurisdiction.

Failure to do so may impair the perfor-

mance of these devices.

The owner is responsible for main-

taining their fire protection system

and devices in proper operating con-

dition. Contact the installing contrac-

tor or product manufacturer with any

questions.

Design

Criteria

TYCO Model TY-QRF 5.6K Quick

Response, Standard Coverage, Flush

Pendent Sprinklers are intended for

fire protection systems designed in

accordance with the standard instal-

lation rules recognized by the appli-

cable listing or approval agency

(e.g., UL Listing is based on NFPA 13

requirements).

Precautionary Warnings for

Corrosive Environments

The Model TY-QRF Flush Pendent

Sprinklers must be installed in a non-

corrosive environment. The improper

use of corrosive agents such as flux,

other products that contain chlo-

ride ions described, whether applied

internally or externally to the sprin-

kler system, may result in corrosion

of the sprinkler head, or stress corro-

sion cracking, which in turn may cause

the sprinklers heads to develop leaks,

operate unexpectedly, or not operate

properly.

Accordingly, it is essential that the

Model TY-QRF Flush Pendent Sprin-

klers be installed only by experienced

fire sprinkler engineers, who comply

fully with NFPA 13 and 25, ASTM B813,

ASTM B828 and Copper Development

Association (CDA).