addition to the standards of any oth-

er authorities having jurisdiction. The

installing contractor or sprinkler man-

ufacturer should be contacted relative

to any questions.

It is recommended that automatic

sprinkler systems be inspected, test-

ed, and maintained by a qualified In-

spection Service in accordance with

local requirements and/or national

code.

Care and

Maintenance

The Series TY-FRL Sprinklers must

be maintained and serviced in accor-

dance with the following instructions:

NOTICE

Before closing a fire protection sys-

tem main control valve for mainte-

nance work on the fire protection sys-

tem that it controls, permission to shut

down the affected fire protection sys-

tem must be obtained from the prop-

er authorities and all personnel who

may be affected by this action must be

notified.

Absence of an escutcheon, which is

used to cover a clearance hole, may

delay the time to sprinkler operation in

a fire situation.

Sprinklers that are found to be leaking

or exhibiting visible signs of corrosion

must be replaced.

Automatic sprinklers must never be

painted, plated, coated or otherwise

altered after leaving the factory. Modi-

fied or over-heated sprinklers must be

replaced.

Care must be exercised to avoid dam-

age to the sprinklers -before, during,

and after installation. Sprinklers dam-

aged by dropping, striking, wrench

twist/slippage, or the like, must be

replaced.

The owner is responsible for the in-

spection, testing, and maintenance

of their fire protection system and de-

vices in compliance with this docu-

ment, as well as with the applicable

standards of the National Fire Pro-

tection Association (e.g., NFPA 25), in

manufacturer’s warranties, as well as

possibly void the sprinkler’s Approvals

and/or Listings.

Installation

The Series TY-FRL Sprinklers must be

installed in accordance with the fol-

lowing instructions:

NOTICE

A leak tight 1/2 inch NPT sprinkler joint

should be obtained with a torque of 7

to 14 ft.lbs. (9,5 to 19,0 Nm). A maxi-

mum of 21 ft. lbs. (28,5 Nm) of torque

may be used to install sprinklers with

1/2 NPT connections. A leak tight 3/4

inch NPT sprinkler joint should be ob-

tained with a torque of 10 to 20 ft.lbs.

(13,4 to 26,8 Nm). A maximum of 30

ft.lbs. (40,7 Nm) of torque is to be used

to install sprinklers with 3/4 NPT con-

nections. Higher levels of torque may

distort the sprinkler inlet and cause

leakage or impairment of the sprinkler.

Do not attempt to make-up for insuf-

ficient adjustment in the escutcheon

plate by under- or over-tightening the

sprinkler. Readjust the position of the

sprinkler fitting to suit.

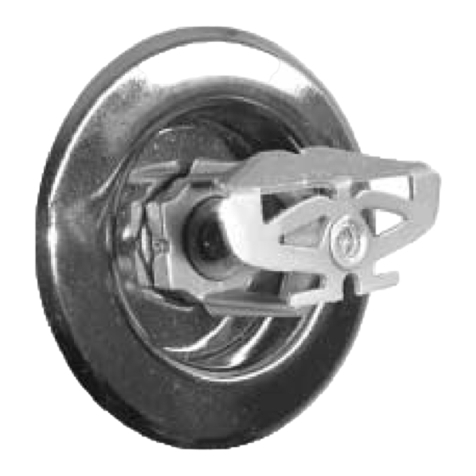

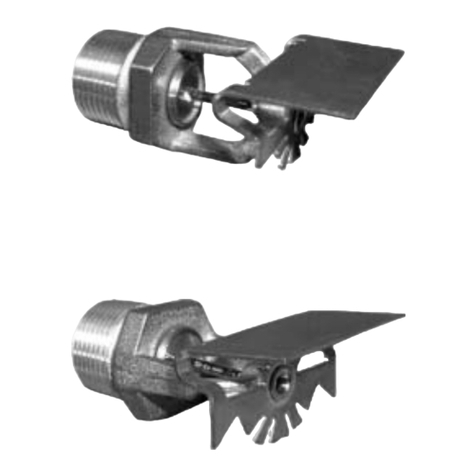

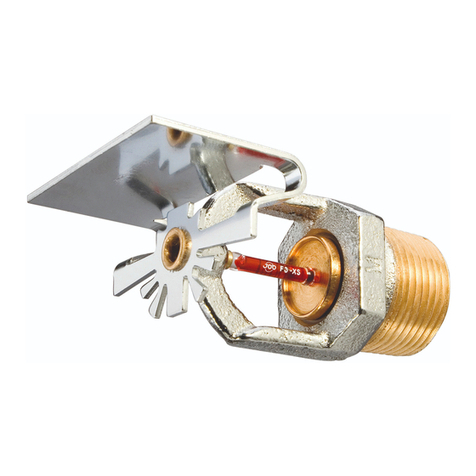

Step 1. The Series TY-FRL Horizontal

Sidewall Sprinklers must be installed

with their centerline of waterway par-

allel to the ceiling and perpendicu-

lar to the back wall surface. The word

“TOP” on the deflector must face up-

wards toward the ceiling.

Step 2. After installing an escutcheon

(as applicable) over the sprinkler pipe

threads and with pipe thread seal-

ant applied to the pipe threads, hand

tighten the sprinkler into the sprinkler

fitting.

Step 3. Tighten the sprinkler into the

sprinkler fitting using only the W-Type

9 Sprinkler Wrench (Ref. Figure 3).

With reference to Figure 1 or 2, the W-

Type 9 Sprinkler Wrench is to be ap-

plied to the wrench area.

NOTES:

Listed by Underwriters Laboratories, Inc. (UL) per Table B.1.

Listed by Underwriters Laboratories, Inc. for use in Canada per Table B.2.

Approved by Factory Mutual Research Corporation (FM) per Table C.3.

Approved by the City of New York under MEA 112-04-E.4.

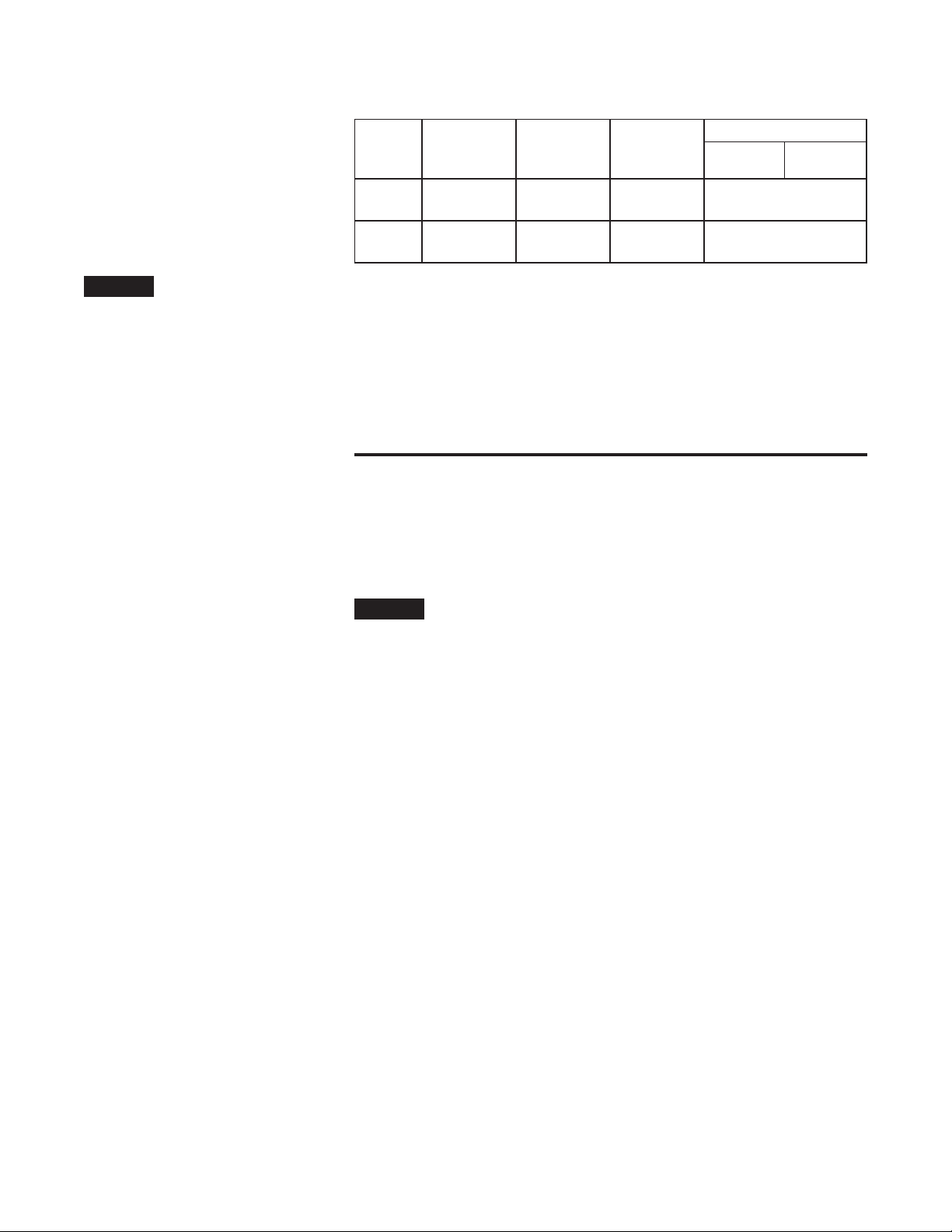

TABLE A

LABORATORY LISTINGS AND APPROVALS

(Refer to the Design Criteria Section)

KTYPE T EMP.

RATING

FRAME

COLOR

CODE

SPRINKLER FINISH

NATURAL

BRASS

CHROME

PLATED

5.6

1/2” NPT

EC HSW

(TY3322) 165º F/74ºC Unpainted 1, 2, 3, 4

8.0

3/4” NPT

EC HSW

( TY4 32 2 ) 165ºF/74º C Unpainted 1, 2, 3, 4

Page 2 of 6 TFP280