TFP417 Page 3 of 6

Technical

Data

Approvals:

UL and C-UL Listed (Refer to Table A

and the Design Criteria section - Re-

cessed and Non-Recessed).

FM Approved (Refer to Table B

and the Design Criteria section - Re-

cessed and Non-Recessed).

Maximum Working Pressure:

175 psi (12,1 bar)

Discharge Coefficient:

K = 5.8 GPM/psi1/2 (83,5 LPM/bar1/2)

Temperature Rating:

155°F (68°C) or 175°F (79°C)

Finishes:

White Polyester Coated, Chrome

Plated, or Natural Brass

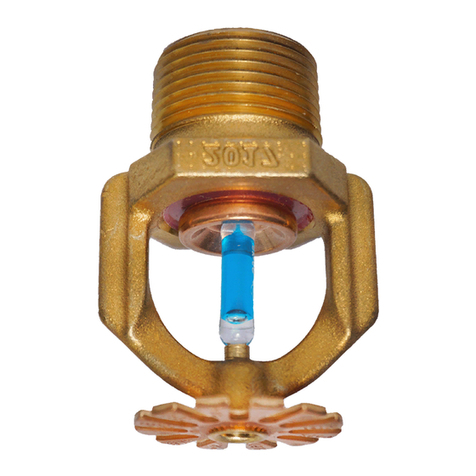

Physical Characteristics:

Frame.................... Brass

Button................... Bronze

Sealing Assembly. . . . . . . . . . . . . . . .

Beryllium Nickel w/Teflon †

Bulb . . . . . . . . . . . . . 3 mm dia. Glass

Compression Screw. . . . . . . . Bronze

Deflector.................. Brass

Ejection Spring. . . . . . Stainless Steel

†Dupont Registered Trademark

Operation

The glass bulb contains a fluid which

expands when exposed to heat. When

the rated temperature is reached, the

fluid expands sufficiently to shatter the

glass bulb, allowing the sprinkler to

activate and water to flow.

Design Criteria

UL AND C-UL LISTING CRITERIA

The Series LFII (TY4334) Residential

Horizontal Sidewall Sprinklers are UL

and C-UL Listed for installation in ac-

cordance with the following criteria.

NOTE

When conditions exist that are outside

the scope of the provided criteria, re-

fer to the Residential Sprinkler Design

Guide TFP490 for the manufacturer’s

recommendations that may be ac-

ceptable to the local Authority Having

Jurisdiction.

System Type. Only wet pipe systems

may be utilized.

Hydraulic Design. The minimum re-

quired sprinkler flow rate for systems

designed to NFPA 13D or NFPA 13R

are given in Table A as a function of

temperature rating and the maximum

allowable coverage areas. The sprin-

kler flow rate is the minimum required

discharge from each of the total num-

ber of “design sprinklers” as specified

in NFPA 13D or NFPA 13R.

For systems designed to NFPA 13, the

number of design sprinklers is to be

the four most hydraulically demanding

sprinklers. The minimum required dis-

charge from each of the four sprinklers

is to be the greater of the following:

• The flow rates given in Table A for

NFPA 13D and 13R as a function of

temperature rating and the maximum

allowable coverage area.

• A minimum discharge of 0.1 gpm/

sq. ft. over the “design area” com-

prised of the four most hydraulically

demanding sprinklers for the actual

coverage areas being protected by

the four sprinklers.

Example No. 1: A corridor being pro-

tected is 8 ft. wide; consequently, an

actual coverage area of 8 ft. x 20 ft.

is being contemplated. Based on us-

ing the LFII (TY4334) Residential Hor-

izontal Sidewall Sprinklers, the flow

rate provided in Table A for a 16 ft x

20 ft. coverage area is 29 GPM. How-

ever based on minimum discharge of

0.1 gpm/sq. ft. the flow rate would be

16 GPM. In this case a minimum flow

rate of 29 GPM for this design sprin-

kler must be utilized.

Example No. 2: The room being pro-

tected is 16 x 16 ft.. Based on using

the LFII (TY4334) Residential Hori-

zontal Sidewall Sprinklers, the flow

rate provided in Table A for a 16 ft. x

16 ft. coverage area is 21 GPM. How-

ever based on minimum discharge of

0.1 gpm/sq. ft. the flow rate would be

26 GPM. In this case a minimum flow

rate of 26 GPM for this design sprin-

kler must be utilized.

Obstruction To Water Distribution.

Locations of sprinklers are to be in ac-

cordance with the obstruction rules of

NFPA 13 for residential sprinklers.

Operational Sensitivity. The sprin-

klers are to be installed with an end-of-

deflector-boss to wall distance of 1-3/8

to 6 inches or in the recessed position

using only the Style 20 Recessed Es-

cutcheon as shown in Figure 2.

In addition the top-of-deflector-to-

ceiling distance is to be within the

range (Ref. Table A) being hydraulically

calculated.

Sprinkler Spacing. The minimum

spacing between sprinklers is 8 feet

(2,4 m). The maximum spacing be-

tween sprinklers can not exceed the

width of the coverage area (Ref. Table

A) being hydraulically calculated (e.g.,

maximum 12 feet for a 12 ft. x 12 ft.

coverage area, or 16 feet for a 16 ft. x

20 ft. coverage area).

FM APPROVAL CRITERIA

The Series LFII (TY4334) Residen-

tial Horizontal Sidewall Sprinklers are

FM Approved for installation in accor-

dance with the applicable Factory Mu-

tual Loss Prevention Data Sheet. Cri-

teria provided by FM may differ for UL

and/or NFPA, therefore the designer

should review and become familiar

with Factory Mutual requirements be-

fore proceeding with design

NOTE

When conditions exist that are outside

the scope of the provided criteria, re-

fer to the Residential Sprinkler Design

Guide TFP490 for the manufacturer’s

recommendations that may be ac-

ceptable to the local Authority Having

Jurisdiction.

The following information pertaining to

System Type, Hydraulic Design, and

Sprinkler spacing are provided for ref-

erence and are not intended to provide

complete installation criteria as pro-

vided in the applicable Factory Mutual

Loss Prevention Data Sheet.

System Type. Only wet pipe systems

may be utilized.

Hydraulic Design. The number of de-

sign sprinklers is to be the four most

hydraulically demanding sprinklers.

The minimum required discharge from

each of the four sprinklers is to be

greater than the following:

• The flow rates given in Table B as a

function of the maximum allowable

coverage area.

• A minimum discharge of 0.1 gpm/

sq. ft. over the “design area” com-

prised of the four most hydraulically

demanding sprinklers for the actual

coverage areas being protected by

the four sprinklers.

Example No. 1: A corridor being pro-

tected is 8 ft. wide; consequently, an

actual coverage area of 8 ft. x 20 ft.

is being contemplated. Based on us-

ing the LFII (TY4334) Residential Hor-

izontal Sidewall Sprinklers, the flow

rate provided in Table B for a 16 ft x

20 ft. coverage area is 32 GPM. How-

ever based on minimum discharge of

0.1 gpm/sq. ft. the flow rate would be

16 GPM. In this case a minimum flow

rate of 32 GPM for this design sprin-

kler must be utilized.

Example No. 2: The room being pro-

tected is 16 x 16 ft.. Based on using

the LFII (TY4334) Residential Hori-

zontal Sidewall Sprinklers, the flow

rate provided in Table B for a 16 ft x

16 ft. coverage area is 24 GPM. How-

ever based on minimum discharge of

0.1 gpm/sq. ft. the flow rate would be

26 GPM. In this case a minimum flow

rate of 26 GPM for this design sprin-

kler must be utilized.

(Continued on Page 5)