TFP330

Page 2 of 4

Design

Criteria

UL and C-UL Listing Requirements

The TYCO 16.8 K-factor, Ultra K17,

Standard Response, Upright Control

Mode Specific Application Sprin-

kler may be installed in accordance

with NFPA 13 “Control Mode Spe-

cific Application Sprinkler (for Storage

Use)” requirements to provide ceiling

only protection (that is, no in-rack

sprinklers) for high piled storage occu-

pancies (Solid-piled, palletized and

rack storage including but not limited to

Class I-IV and Group A plastics) using

the criteria from NFPA 13.

FM Approval Requirements

The TYCO 16.8 K-factor, Ultra K17

(TY7153) Sprinklers may be installed

with the applicable “storage sprinkler”

guidelines provided by Factory Mutual.

(FM guidelines may differ from UL and

C-UL Listing criteria.)

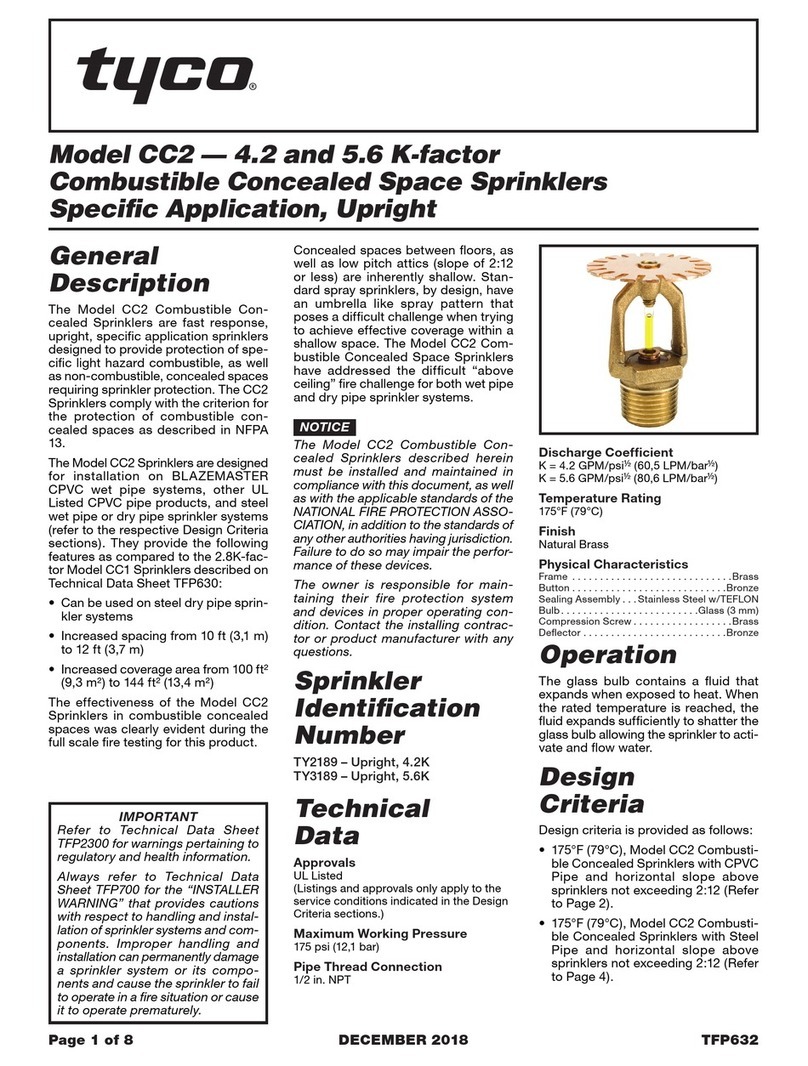

Operation

The glass bulb contains a fluid that

expands when exposed to heat. When

the rated temperature is reached, the

fluid expands sufficiently to shatter the

glass bulb, allowing the sprinkler to

activate and flow water.

Installation

The TYCO 16.8 K-factor, Ultra K17,

Standard Response, Upright Control

Mode Specific Application Sprinkler

must be installed in accordance with

this section.

General Instructions

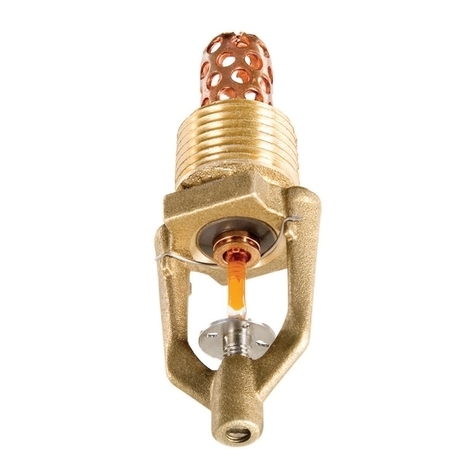

Do not install any bulb type sprinkler

if the bulb is cracked or there is a loss

of liquid from the bulb. With the sprin-

kler held horizontal, a small air bubble

should be present. The diameter of the

air bubble is approximately 1/16 inch

(1,6 mm).

NOTICE

Obtain a 3/4 inch NPT sprinkler joint

by applying a minimum to maximum

torque of 7 to 14 ft.-lbs. (9,5 to 19,0

Nm). Higher levels of torque can distort

the sprinkler Inlet with consequent

leakage or impairment of the sprinkler.

Step 1. With pipe thread sealant

applied to the pipe threads, hand

tighten the Ultra K17 Sprinkler into the

sprinkler fitting.

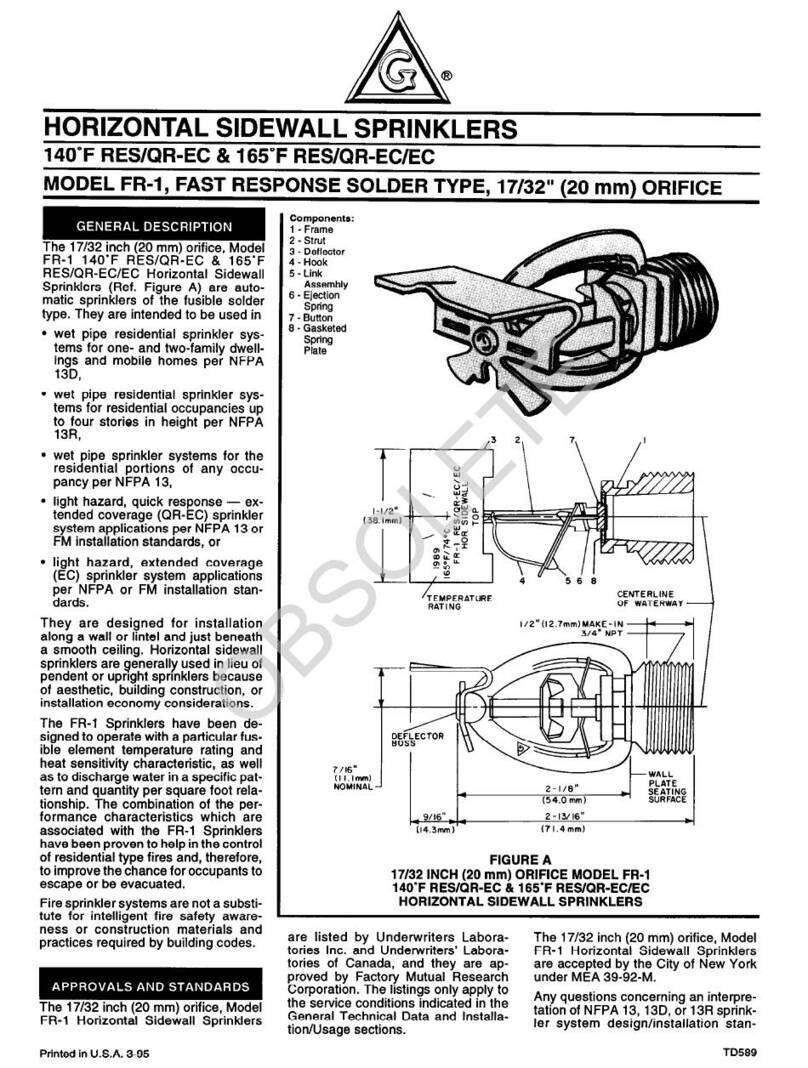

Step 2. Using the W-Type 8 Sprinkler

Wrench (Ref. Figure 2) applied to the

sprinkler Wrench Flats (Ref. Figure 1),

tighten the Ultra K17 Sprinkler into the

sprinkler fitting.

Care and

Maintenance

The TYCO 16.8 K-factor, Ultra K17,

Standard Response, Upright Control

Mode Specific Application Sprinkler

must be maintained and serviced in

accordance with this section.

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system that

it controls, permission to shut down the

affected fire protection systems must

be obtained from the proper authorities

and all personnel who may be affected

by this action must be notified.

Sprinklers that are found to be leaking

or exhibiting visible signs of corrosion

must be replaced.

Automatic sprinklers must never be

painted, plated, coated, or other-

wise altered after leaving the factory.

Modified sprinklers must be replaced.

Sprinklers that have been exposed to

corrosive products of combustion, but

have not operated, should be replaced

if they cannot be completely cleaned

by wiping the sprinkler with a cloth or

by brushing it with a soft bristle brush.

Care must be exercised to avoid

damage to the sprinklers - before,

during, and after installation. Sprin-

klers damaged by dropping, striking,

wrench twist/slippage, or the like, must

be replaced. Also, replace any sprin-

kler that has a cracked bulb or that has

lost liquid from its bulb. (Ref. Installa-

tion Section).

SPRINKLER FINISH

TYPE TEMPERATURE BULB

LIQUID NATURAL BRASS WITH

CHROME DEFLECTOR

UPRIGHT K = 16.8 (TY7153)

155°F (68°C) Red 3, 4

200°F (93°C) Green 1, 2, 3, 4

NOTES:

a. Listed by Underwriters Laboratories, Inc. (UL Listed)

b. Listed by Underwriters Laboratories, Inc. for use in Canada (C-UL Listed)

c. Approved by Factory Mutual Research Corporation (FM Approved)

d. Approved by the City of New York under MEA 177-03-E

TABLE A

LABORATORY LISTINGS AND APPROVALS

(REFER TO THE DESIGN CRITERIA SECTION)