TFP720

Page 7 of 8

Installation

The TYCO FASTFLEX Flexible Sprin-

kler Hose, as shown in Figure 1, must

be installed in accordance with this

section as follows:

NOTICE

FASTFLEX Flexible Sprinkler Hoses

are intended only to connect sprin-

klers directly to system piping as

shown in Figure 1. FASTFLEX Sprin-

kler Hoses cannot be joined together

to form longer hoses. Joining flexible

hoses together creates an assembly

with unknown performance that has

not been accounted for in system cal-

culations or safe product performance.

Step 1. Review the Design Criteria

section that applies to the Approval

agency recognized by the authority

having jurisdiction, as well as Figure 3

that provides installation guidance.

Step 2. Determine the approximate

place where the sprinkler will be

located. The support bar is 700 mm

long and shall be mounted on the

600 mm width of the ceiling grid. The

sprinkler should be located as close as

possible to the center of the distance

between ceiling grid T-bars.

Step 3. Slide the reducer bracket onto

the support Bar. Loosely attach the

reducer bracket and the two bar xing

clamps on the support bar and place

the bar xing clamps such that the

support bar crosses the location where

the sprinkler will be located.

Step 4. Attach one end of the ex-

ible hose onto the sprinkler reducer.

Applying the wrench to the slip nut,

and not to the exible hose, tighten to

a maximum torque of 35 N·m.

Step 5. Attach the inlet nipple on to the

branch line. Ensure that the arrow is in

the appropriate direction of ow to the

sprinkler and to use pipe thread sealant

at the connection to the branchline.

Attach one end of the exible hose on

to the inlet nipple. Applying the wrench

to the slip nut, and not to the exible

hose, tighten to a maximum torque of

35 N·m. Do not twist the exible hose.

Step 6. Bend the exible hose into

a curve(s) that locates the sprinkler

reducer at the other end of the exible

hose in the area where the sprinkler will

be located. The tube arc should not be

twisted, and the arc should be as large

and smooth as possible.

NOTICE

For minimum bend criteria, refer to the

Design Criteria section that applies to

the Approval agency recognized by the

authority having jurisdiction.

A bend radius smaller than pro-

vided by the minimum bend criteria

may adversely effect the friction loss

specifications stated by the approval

laboratory.

For assembly lengths greater than

1800 mm, the exible hose shall be

supported to the structure to ensure

that the maximum unsupported length

does not exceed 1800 mm. In these

cases, it is recommended that the tube

be secured to a xed mounting point

every 600 mm, in order to provide a

more stable installation.

Step 7. Insert the sprinkler reducer

into the reducer bracket. Locate the

reducer bracket and sprinkler reducer

where the sprinkler will be, and loosely

tighten the buttery bolt on the reducer

bracket.

Step 8. Attach the sprinkler to the

sprinkler reducer. Put a wrench on

the sprinkler reducer to counteract

the tightening torque and prevent the

exible hose from twisting. Reference

the sprinkler manufacturer’s sprinkler

data sheet for appropriate sprinkler

tightening torque, sprinkler wrench,

and other guidance.

Step 9. Verify that the sprinkler reducer

is seated in the reducer bracket. Pre-

cisely locate the sprinkler in all three

axes in accordance with the sprinkler

manufacturer’s data sheet. Tighten the

buttery bolts on the bar xing clamps

and the reducer bracket. The tightening

torque for the bar xing clamp fastener

is 4,5 to 5,7 N·m, and the tightening

torque for the reducer bracket fastener,

is a minimum of 2,3 N·m.

Step 10. After tightening all the but-

tery bolts, verify that the sprinkler is

properly located in accordance with

the manufacture’s instructions. If not,

loosen the buttery bolts and readjust

as required.

Care and

Maintenance

The TYCO FASTFLEX Flexible Sprinkler

Hose must be maintained and serviced

in accordance with this section.

Before closing a re protection system

control valve for inspection or main-

tenance work on the re protection

system that it controls, permission to

shut down the effected re protection

system must rst be obtained from

the proper authorities and all person-

nel who may be affected by this action

must be notied.

After placing a re protection system

in service, notify the proper authorities

and advise those responsible for moni-

toring proprietary and/or central station

alarms.

The owner is responsible for the inspec-

tion, testing, and maintenance of their

re protection system and devices in

compliance with this document, as well

as with the applicable standards of the

authorities having jurisdiction. Contact

the installing contractor or product

manufacturer with any questions.

Automatic sprinkler systems are rec-

ommended to be inspected, tested,

and maintained by a qualied Inspec-

tion Service in accordance with local

requirements and/or national codes.

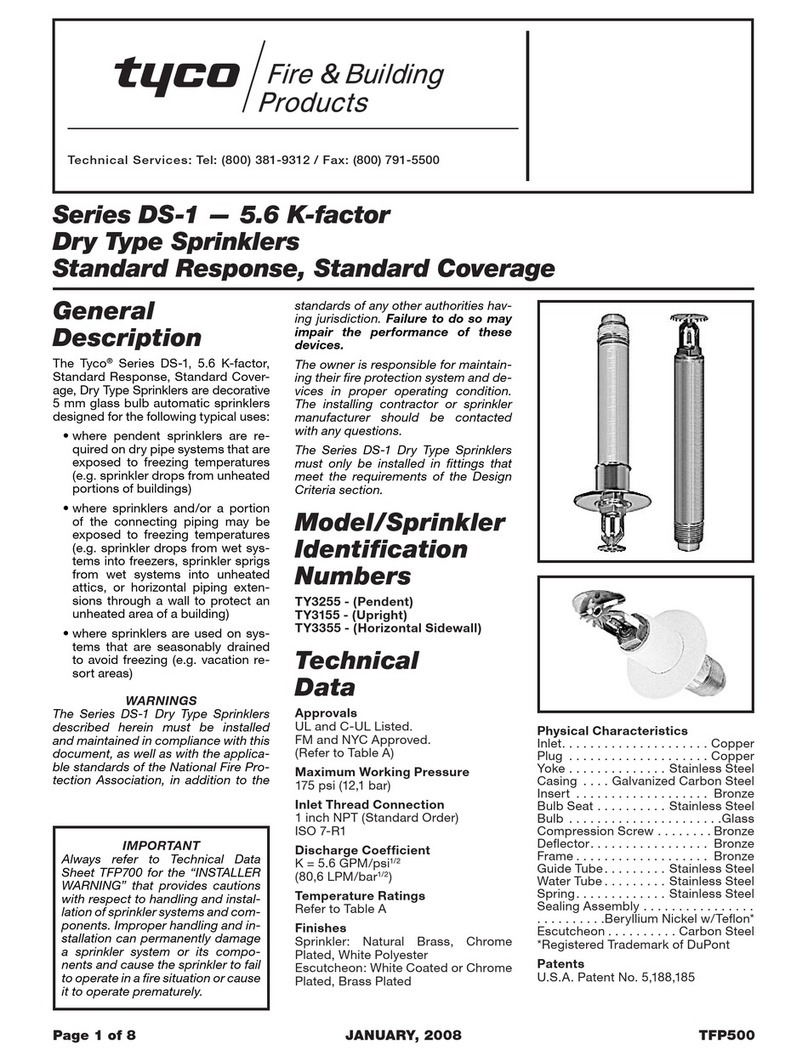

ISO 7-R 1

OR ISO 7-R 1 1/4

MACHINE HOSE

THREADED

FITTING

OUTLET

NUT

HOSE TO

NIPPLE

DO assemble the FASTFLEX Inlet Nipple with the direction

of ow arrow properly oriented to avoid mismatched threads.

FIGURE 3

FASTFLEX FLEXIBLE SPRINKLER HOSE

INSTALLATION GUIDANCE