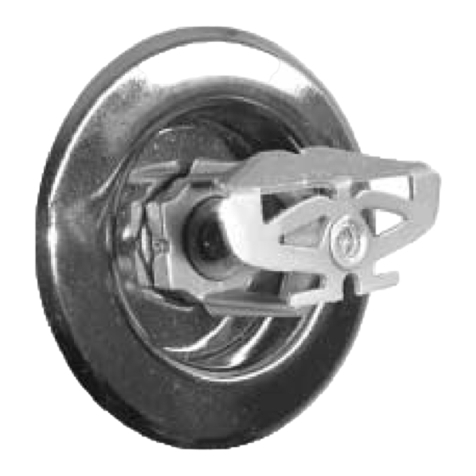

Operation

In the standby condition, the unique

features of the RAVEN provide a tam-

per resistant sprinkler design that

helps reduce the opportunity for indi-

viduals to injure themselves or others

with components of a fire sprinkler.

The RAVEN has been specifically de-

signed to minimize components, as

well as holes or shapes that could

provide a point for securing an exter-

nal non-sprinkler associated object.

Also, when properly installed, the es-

cutcheon is held fast to the ceiling or

wall to deter its removal. The shape of

the sprinkler and escutcheon cannot

be grasped easily, which further de-

ters tampering.

A link assembly covers the sealing as-

sembly. The link is soldered with an

eutectic solder that melts when ex-

posed to heat. When the link reaches

its rated temperature, the link sepa-

rates and releases the sealing assem-

bly, allowing the deflector assembly

to extend from the body and water to

flow.

Installation

The Tyco®RAVEN™ Institutional

Sprinklers must be installed in accor-

dance with the following instructions:

NOTICE

Refer to the Design Criteria section for

important information regarding the

piping installation design and its ef-

fect on maintaining the integrity of the

tamper resistant design of the Institu-

tional Escutcheons.

A 1/2 inch NPT sprinkler joint should

be obtained with a minimum to max-

imum torque of 7 to 14 ft.lbs. (9,5 to

19,0 Nm). Higher levels of torque may

damage the sprinkler with consequent

leakage or impairment of the sprinkler.

Do not attempt to compensate for

improper location of the sprinkler fit-

ting by under-or over-tightening the

sprinkler.

After the installation is complete,

make certain that the RAVEN Es-

cutcheon is held fast (i.e., tight with

no movement or gap) to the mounting

surface and that the Escutcheon sits

squarely against the mounting sur-

face around the entire perimeter of the

Escutcheon.

PENDENT SPRINKLERS

Step 1. The RAVEN Pendent Sprinkler

must be installed pendent and with

the centerline of the waterway perpen-

dicular to the ceiling.

Step 2. With the Escutcheon in place

and with pipe thread sealant applied

to the pipe threads, hand tighten the

sprinkler into the sprinkler fitting using

the W-type 25 Sprinkler Wrench.

Note: The sprinkler has intention-

ally been designed to be difficult to

grasp by hand; therefore, the use of

the W-type 25 Sprinkler Wrench for

hand tightening will assist in thread-

ing the sprinkler. Also use of the W-

type 25 Sprinkler Wrench will help

avoid damage to the Sprinkler during

installation.

Step 3. Wrench tighten the Sprinkler

using only the W-Type 25 Sprinkler

Wrench (Ref. Fig. 3) with the wrench

prongs fully engaged with the Sprin-

kler Wrenching Notches. The wrench

prongs are designed to engage with

the wrenching notches in the sprin-

kler body. The wrench prongs are

also uniquely spaced to align with the

sprinkler wrenching notches in one

position.

Note: To help prevent slippage of the

Sprinkler Wrench and while using a 1/2

inch ratchet drive, place one hand over

the Sprinkler Wrench while tightening

with the other hand.

Step 4. After the installation is com-

plete, make certain that the RAVEN

Escutcheon is held fast to the mount-

ing surface and that it sits squarely

against the ceiling around its entire

perimeter. When using the technique

shown in Figure 7, the Escutcheon can

be pulled up onto the ceiling by pulling

up on the sprinkler/supply pipe and

then tighten the Retaining Flange Set

Screw. See Figure 3 inset for post in-

stallation identification.

Note: If the Escutcheon is NOT held

fast (i.e., tight with no movement or

gap) to the mounting surface and as

an option to relocating the sprinkler

pipe fitting (i.e., increasing the “face of

fitting” to “face of mounting surface”

distance) up to two Adjustment Spac-

er Rings as shown in Figure 3 may be

utilized. Each Adjustment Spacer Ring

can account for 0.075 inches of gap

between the Escutcheon and mount-

ing surface. Therefore, if the gap is

greater than 0.150 inches, the sprin-

kler fitting will need to be relocated

to assure proper installation of the

RAVEN Sprinkler and Escutcheon.

HORIZONTAL SIDEWALL

SPRINKLERS

Step 1. The RAVEN Horizontal Side-

wall Sprinkler must be installed with

the centerline of their waterway paral-

lel with the ceiling and perpendicular

to the back wall.

Step 2. With the Escutcheon in place

and with pipe thread sealant applied

to the pipe threads, hand tighten the

sprinkler into the sprinkler fitting using

the W-type 25 Sprinkler Wrench.

Note: The sprinkler has intention-

ally been designed to be difficult to

grasp by hand; therefore, the use of

the W-type 25 Sprinkler Wrench for

hand tightening will assist in thread-

ing the sprinkler. Also use of the W-

type 25 Sprinkler Wrench will help

avoid damage to the Sprinkler during

installation.

Step 3. Wrench tighten the Sprinkler

using only the W-Type 25 Sprinkler

Wrench (Ref. Fig. 4) with the wrench

prongs fully engaged with the Sprin-

kler Wrenching Notches. The wrench

prongs are designed to engage with

the wrenching notches in the sprin-

kler body. The wrench prongs are

also uniquely spaced to align with the

sprinkler wrenching notches in one

position so as to assure that the sprin-

kler defector is properly positioned

with respect to the ceiling.

Note: To help prevent slippage of the

Sprinkler Wrench and while using a 1/2

inch ratchet drive, place one hand over

the Sprinkler Wrench while tightening

with the other hand.

Note: Upon completion of tighten-

ing the sprinkler, the word “UP” on the

wrench must be positioned towards

the ceiling. The use of a level applied

the flat of the wrench below the word

“UP” is recommended to help as-

sure that the sprinkler deflector is po-

sitioned correctly with respect to the

ceiling.

Step 4. After the installation is com-

plete, make certain that the Escutch-

eon is held fast to the mounting sur-

face and that it sits squarely against

the wall around its entire perimeter.

When using the technique shown

in Figure 7, the Escutcheon can be

pulled back onto the wall by pulling

back on the sprinkler/supply pipe and

then tighten the Retaining Flange Set

Screw.

Note: If the Escutcheon is NOT held

fast (i.e., tight with no movement or

gap) to the mounting surface and as

an option to relocating the sprinkler

pipe fitting (i.e., increasing the “face of

fitting” to ”face of mounting surface”

distance) up to two Adjustment Spac-

er Rings as shown in Figure 4 may be

utilized. Each Adjustment Spacer Ring

can account for 0.075 inches of gap

between the Escutcheon and mount-

ing surface. Therefore, if the gap is

greater than 0.150 inches, the sprinkler

fitting will need to be relocated to as-

sure proper installation of the RAVEN

Sprinkler and Escutcheon.

Step 5. After all the horizontal sidewall

sprinklers are installed, use the W-

type 25 Sprinkler Wrench to verify that

the each sprinkler defector is proper-

ly aligned with respect to the ceiling.

See Step 3. See Figure 4 inset for post

installation identification.

TFP651 Page 3 of 10