TFP560

Page 3 of 10

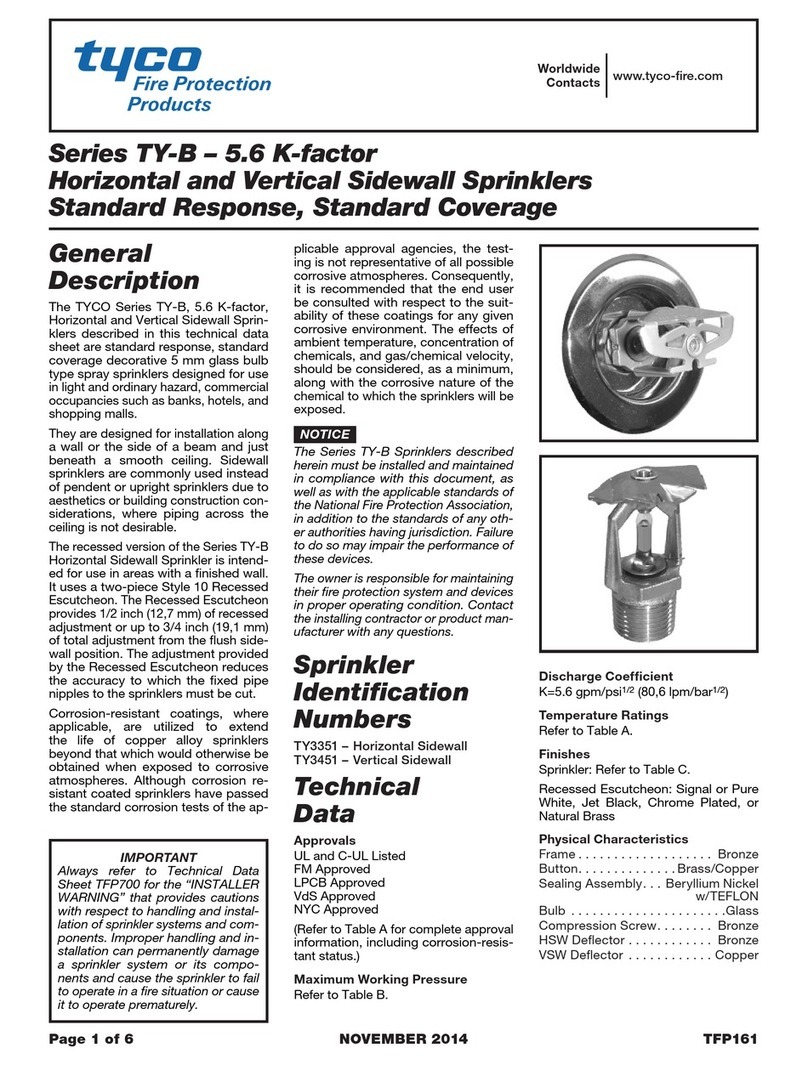

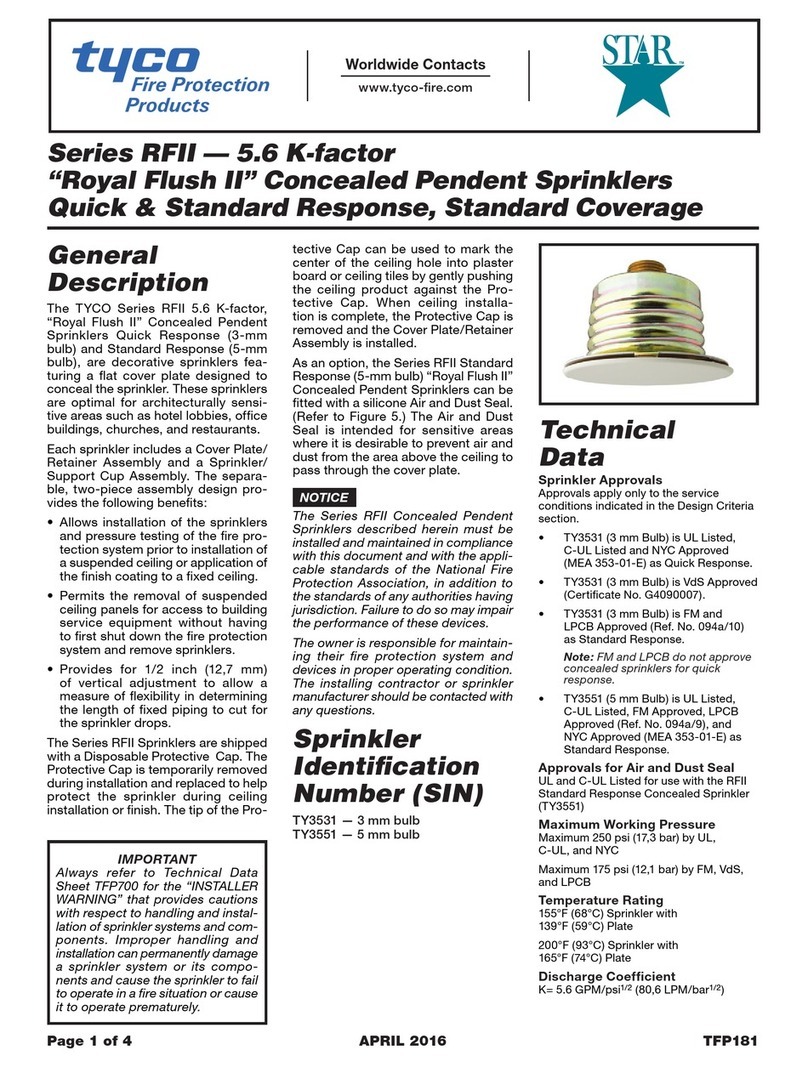

Operation

When TYCO Series DS-1 Stainless

Steel Dry-Type Sprinklers, 5.6K Pen-

dent, Horizontal Sidewall (HSW), and

Extended Coverage HSW, Standard

(5 mm bulb) and Quick (3 mm bulb)

Response are in service, water is pre-

vented from entering the assembly by

the Plug with Sealing Assembly in the

Inlet of the sprinkler. Refer to Figures 1

through 3.

The glass bulb contains a uid that

expands when exposed to heat. When

the rated temperature is reached, the

uid expands sufciently to shatter

the glass bulb then release the Bulb

Seat.

The compressed Spring is then able

to expand and push the Water Tube as

well as the Guide Tube outward. This

outward action simultaneously pulls

inward on the Yoke, withdrawing the

Plug with Sealing Assembly from the

Inlet and allowing the sprinkler to acti-

vate and ow water effectively.

Design

Criteria

TYCO Series DS-1 Stainless Steel Dry-

Type Sprinklers, 5.6K Pendent, Hori-

zontal Sidewall (HSW), and Extended

Coverage HSW, Standard (5 mm bulb)

and Quick (3 mm bulb) Response are

intended for use in re sprinkler sys-

tems designed in accordance with the

standard installation rules recognized

by the applicable Listing or Approval

agency (e.g., UL Listing is based on

NFPA 13 requirements).

For more information on LPCB Ap-

proval, contact Tyco Fire Protection

Products at the following ofce:

Kopersteden 1

7547 TJ Enschede

The Netherlands

Tel: +31-(0)53-428-4444

Fax: +31-(0)53-428-3377

The Series DS-1 Stainless Steel Ex-

tended Coverage Sprinklers are in-

tended for use in re sprinkler systems

designed in accordance with extend-

ed coverage installation guidelines

provided by NFPA 13 and the installa-

tion criteria provided by Table B.

Sprinkler Fittings

Install the 1 inch NPT Series DS-1

Stainless Steel Dry-Type Sprinkler in

the 1 inch NPT outlet or run of one of

the following ttings:

• malleable or ductile iron thread-

ed tee ttings that meet the dimen-

sional requirements of ANSI B16.3

(Class 150)

• cast iron threaded tee ttings that

meet the dimensional requirements

of ANSI B16.4 (Class 125)

Sprinkler

Identification

Numbers (SINs)

Standard Coverage Pendent

• TY3230 – 3 mm Bulb

• TY3250 – 5 mm Bulb

Standard Coverage

Horizontal Sidewall

• TY3337 – 3 mm Bulb

• TY3357 – 5 mm Bulb

Extended Coverage

Horizontal Sidewall

• TY3339 – 3 mm Bulb

Technical

Data

Approvals

UL and C-UL Listed

LPCB Approved: Ref. No. 094a/12

CE Certied: EN 12259-1

(Refer to Tables A and B for details.)

Maximum Working Pressure

175 psi (12,1 bar)

Inlet Thread Connections

1-Inch NPT or

ISO 7-R 1

Discharge Coefficient

K=5.6 gpm/psi1/2 (80,6 lpm/bar1/2)

Temperature Ratings

Refer to Tables A and B.

Finishes

Sprinkler: Stainless Steel

Escutcheon: Stainless Steel

Physical Characteristics

With the exceptions of the bulb, the

Insert, the Deector, and the Seal-

ing Assembly, all components of the

Series DS-1 Stainless Steel Dry-Type

Sprinkler are constructed with Type

316 Stainless Steel.

• The bulb is glass.

• The Insert is 300 Series Stainless

Steel.

• The Deector is Type 316L Stainless

Steel.

The Sealing Assembly consists of a

Disc Spring that is sealed on both its

inside and outside faces with a TEF-

LON gasket. The Disc Spring is 1/2

Hard Beryllium Nickel.

Refer to Figures 1 through 3 for com-

ponent assemblies.

• cast bronze threaded tee ttings

that meet the dimensional require-

ments of ANSI B16.15 (Class 125)

• stainless steel threaded tee ttings

that meet the dimensional require-

ments of MSS SP-114.

Do not install the Series DS-1 Stain-

less Steel Dry-Type Sprinklers into

elbow ttings. The inlet of the sprinkler

can contact the interior of the elbow,

potentially damaging the Inlet seal.

The unused outlet of the threaded tee is

plugged as shown in Figures 4 and 5.

You can also install the Series DS-1

Sprinklers in the 1 Inch NPT outlet of

a GRINNELL Figure 730 Mechanical

Tee. However, the use of the Figure

730 Tee for this arrangement is limited

to wet-pipe systems.

The conguration shown in Figure 4 is

only applicable for wet-pipe systems

where the sprinkler tting and water-

lled pipe above the sprinkler tting

are not subject to freezing and where

the length of the Stainless Steel Dry-

Type Sprinkler has the minimum

exposure length depicted in Figure 6.

Refer to the Exposure Length section.

For wet-pipe system installations of

the 1 Inch NPT Series DS-1 Stainless

Steel Dry-Type Sprinklers connected

to CPVC piping, use only the following

TYCO CPVC ttings:

• 1” x 1” NPT Female Adapter

(P/N 80145)

• 1” x 1” x 1” NPT Sprinkler Head

Adapter Tee (P/N 80249)

For dry-pipe system installations, use

only the side outlet of maximum 2-1/2

inch reducing tee when locating the

Series DS-1 Stainless Steel Dry-Type

Sprinklers directly below the branch

line. Otherwise, use the conguration

shown in Figure 5 to assure complete

water drainage from above the Series

DS-1 Stainless Steel Dry-Type Sprin-

klers and the branchline. Failure to

do so may result in pipe freezing and

water damage.

NOTICE

Do not install the Series DS-1

Stainless Steel Dry-Type Sprinklers

into any other type fitting without first

consulting the Technical Services

Department. Failure to use the

appropriate fitting can result in one of

the following:

• failure of the sprinkler to operate

properly due to formation of ice

over the Inlet Plug or binding of the

Inlet Plug

• insufficient engagement of the In-

let pipe threads with consequent

leakage