0321 IH-2302PAGE 5 OF 7

MAINTENANCE CONTINUED

MAINTENANCE OF THE TRUCK

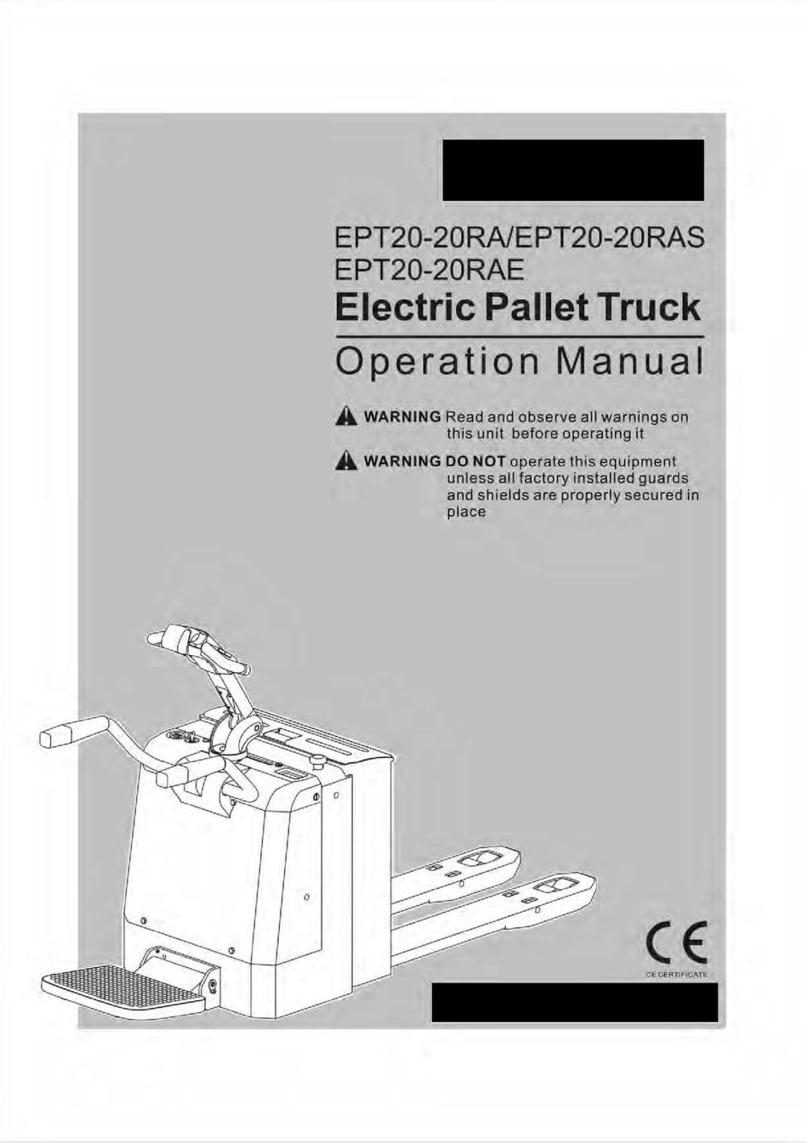

SAFETY OPERATION AND

ENVIRONMENTAL PROTECTION

1. The instructions in the tables titled "Maintenance List"

(On pages 6 and 7) should be performed based

on the time interval specified in the Maintenance

Schedule below.

2. To ensure the safety and reliability of truck operation,

only spare parts from manufacturer should be used.

3. Any parts replaced, including oils, must be disposed

of according to related environmental protection

regulations.

SAFETY RULES FOR PALLET TRUCK MAINTENANCE

1. MAINTENANCE STAFF – Repair and maintenance

of the truck should only be performed by qualified

professionals.

2. CLEANING OPERATION – Flammable fluid is strictly

forbidden in the cleaning of the truck. Before

cleaning starts, safety measures must be taken

to avoid sparking caused by a short circuit. Any

cleaning should be performed after disconnecting

the battery. All electric elements and electronic

assemblies can only be cleaned by compressed air

or by an anti-static brush.

3. OPERATION OF ELECTRICAL SYSTEM – Maintenance

of electrical system of the truck should be

performed by trained professionals only. Before

any maintenance of electric system, protective

measures to avoid electric shock should be taken

by disconnecting the battery from the truck.

4. WHEELS – The condition of the wheels will greatly

affect stability and driving performance. Wheels

should be replaced in pairs; e.g., both left and right.

5. LIFTING CHAINS – Without lubrication, the lifting

chains will wear out prematurely. The time interval

in maintenance manual is applicable for normal

operation. In case of poor operating conditions

(dust, temperature), it is necessary to increase

lubrication accordingly.

6. HYDRAULIC OIL PIPE – The oil pipe should be

replaced every six years.

NOTE: The maintenance cycle stated in the

instruction manual refers to normal conditions

with single shift operating. Under dusty

conditions, extreme temperatures or under

multiple operating shifts, the maintenance

cycle should be shortened accordingly.

7. Please perform maintenance according to the

following table:

OPERATING ISSUE CAUSES RECOMMENDATIONS

Truck does not

move. Disconnection of battery.

Key switch at "0" position.

Emergency shut-off switch on.

Battery capacity consumed.

Fuse damaged.

Check connection of battery and reconnect if necessary.

Put key switch at "I" position.

Release the emergency shut-off switch.

Check battery capacity and charge battery if necessary.

Check fuses.

Forks will not raise. Control valve is blocked by

dirty fluid.

Check hydraulic oil and clean control valve. Replace

hydraulic oil if necessary.

Traveling too slow. Battery capacity low. Check battery capacity indicator; charge if necessary.

For all other issues please contact Uline Customer Service at 1-800-295-5510.

TROUBLESHOOTING

CODE MAINTENANCE SCHEDULE

W1 Every 50 working hours, at least once per week

M3 Every 500 working hours, at least once per 3 months

M6 Every 1,000 working hours, at least once per 6 months

M12 Every 2,000 working hours, at least once per 12 months