Installation and Maintenance Manual

ENGLISH

page 8 - CYLINDRE HYDRAULIQUE POUR MOTEUR HORS BORD

1 - PRODUCT DESCRIPTION

1.1 Operation of a hydraulic steering system

The hydraulic systems are designed in accordance with UNI EN ISO 10592 rule and A.B.Y.C.

standards P21.

The steering systems are able to operate in an ambient temperature ranging between

-18°C (0°F) and +77°C (+170°F), all of their components were specifically manufactured for the marine

environment, using materials and applying processes that offer great durability and safety even in

extreme conditions.

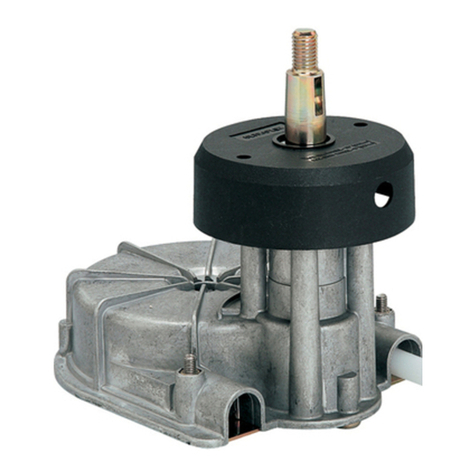

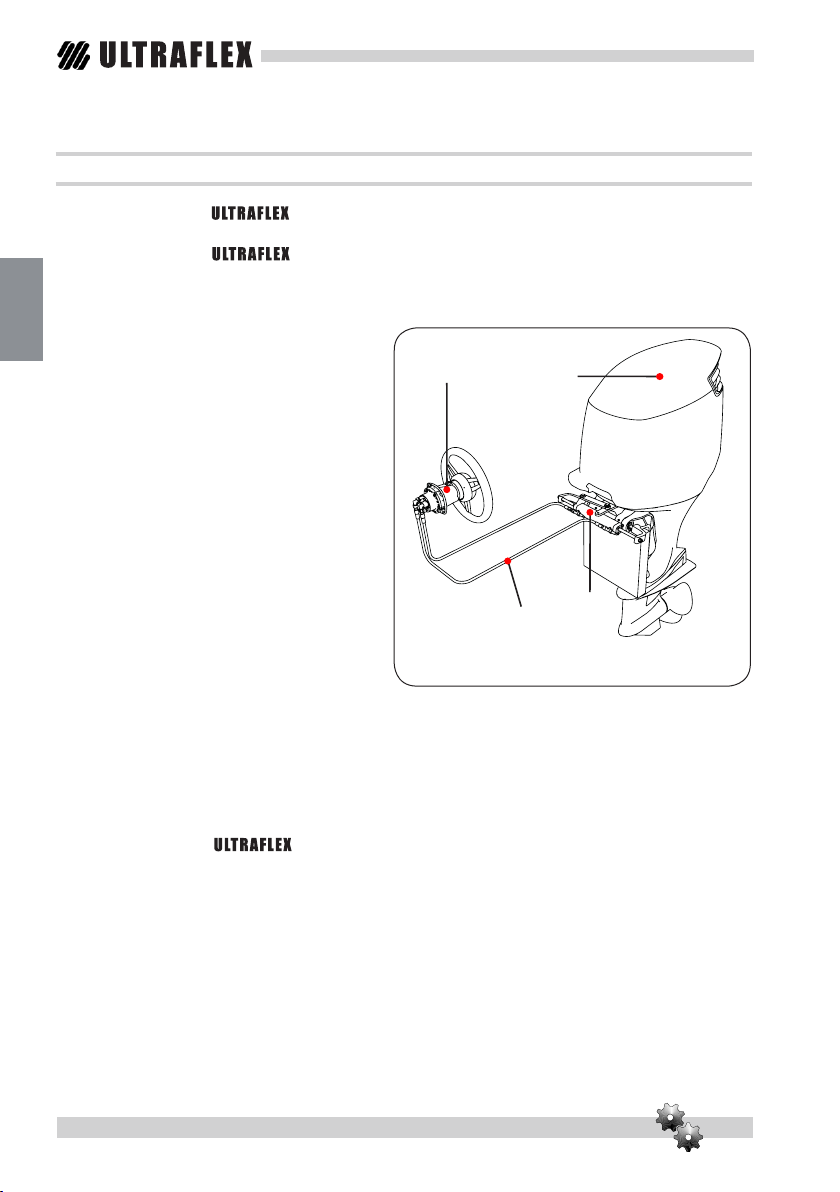

The hydraulic steering system mounted on a

boat schematically consists in:

• a pump placed on the dashboard;

• a cylinder positioned at the stern and

connected to the motor or to the helm;

• pair of connection hydraulic tubes (see

figure).

The rotation of the steering wheel causes

the pumping of the oil that, depending on the

direction of rotation, flows into the cylinder

through the tubes.

Theconsequent movementofthe cylindermakes

the oil flow towards the pump through the tubes

and at the same time moves the engine or the

helm of the boat connected to the cylinder itself.

The pumps are equipped with a non-return

valve, which has the function of preventing the

flow of oil to the pump if the latter is not running. In unbalanced cylinders the two chambers have different

capacities, and therefore require, considering the same displacement in the two directions, a different

number of turns of the steering wheel and a different rotation torque on the steering wheel. The balanced

cylinders require the same number of turns of the steering wheel to move the helm from the centre to the

end of stroke in the two opposite directions.

A balanced and easily manoeuvrable steering system requires a proper choice of the type of pump to be

coupled to the cylinder. builds different models of pumps, which differ for the flow rate (cm3

of oil handled at each turn of the steering wheel) and for the type of installation. While choosing the pump

you must consider the capacity of the cylinder: the number of steering wheel turns from left to right is in

fact determined by the ratio between the volume of the cylinder and the pump flow.

Example: if the pump has a flow rate of 18 cm3 [1.2 cu.in.] and the cylinder has a capacity of 81 cm3

[5.7cu.in], then the following formula applies: 81/18=4,5. Therefore the steering wheel will rotate about

4 and a half times before the cylinder is completely shifted from side to side. Couplings with less than

4 turns are not recommended as they require excessive driving strength, neither those with more than

8 turns are advisable as they make the board slow in responding to the steering gear. The maximum

operating pressure is equal to 5,5MPa (55 bars) (800 psi).

pump motor

cylinder

hydraulic tubes

example of application