Uponor Smatrix Base PRO Controller X-147 Modbus RTU interface l Installation manual l 3

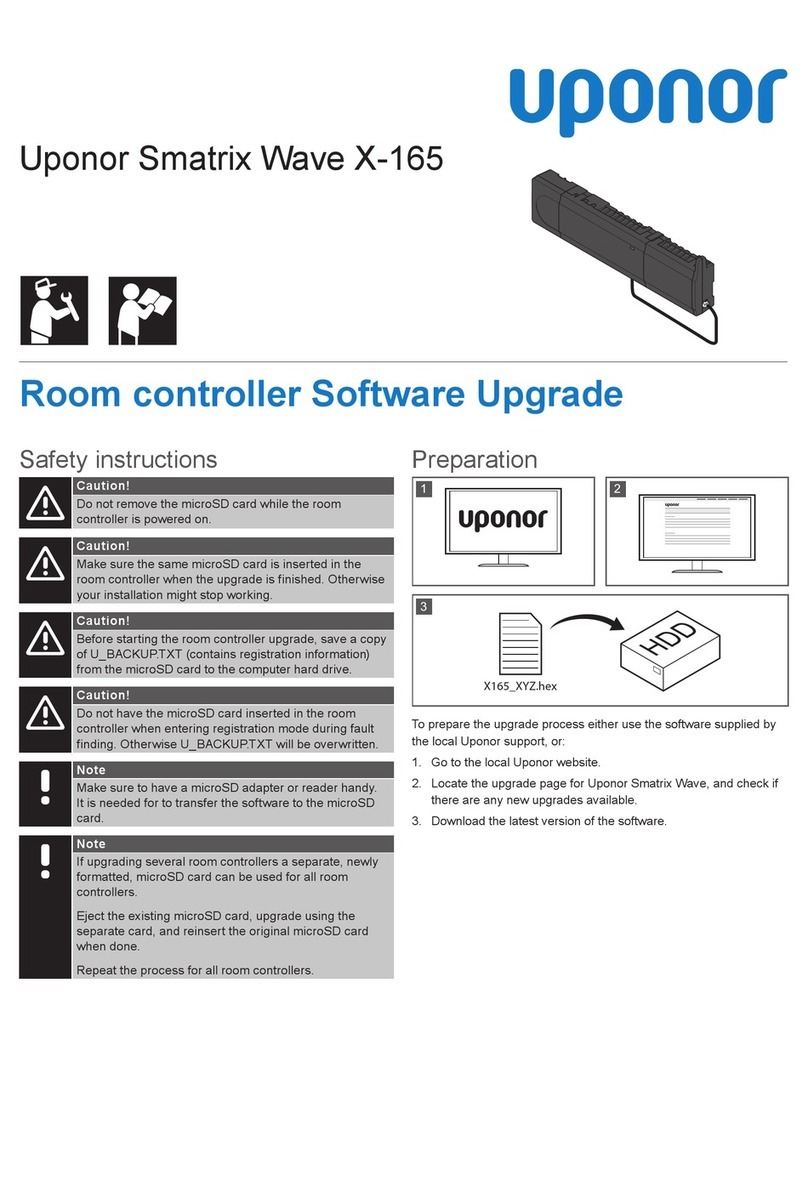

X147_XYZ.hex

# 1

# 2

# ...

2

3

10 s

U_BMS.txt

U_BMS.txt

U_BMS.txt

# 1 Slave 1

# 2

# ...

Slave 2

Slave ...

4

Slave 1 Slave 2 Slave ...

5

Slave 1 Slave 2 Slave ...

BMS

6

To connect a BMS to the Uponor Smatrix Base PRO controller some

preparations must be made.

1. Connect and register thermostats, and system devices, to the

controllers.

Caution!

If an Uponor Smatrix Base PRO Interface I-147 is

connected, it must be unregistered and disconnected.

Note

Make sure that the thermostats are registered to

consecutive channels so the BMS can read and write

all channels in an efcient way. That is, addressing

multiple channels in one message.

See Uponor Smatrix Base PRO installation and operation manual,

or quick guide, for information registering devices to the controller.

2. Update the software of the controllers with the Modbus RTU

compatible software (available on the Uponor website).

See separate documentation for information on how to update the

software of a controller.

3. Press the <, OK, and >buttons simultaneously (for about

10 seconds) until the power LED ashes, and all channel LEDs

turn off. The controller has been reset to factory default.

4. Edit the U_BMS.txt le, on the controller microSD card, to setup

the controller Modbus RTU interface.

Available settings (default in bold):

- BMS Slave address: 1to 247

- BMS Baud rate: 19200 or 9600

- BMS Parity: even, odd, or no

- Heat pump integration via BMS: off or on

on = enables dynamic heat curve offset in integrated heat

pump, and integrated heat pump defrost state.

- Exclude zone from heat curve offset calculation:

0, or 1 through 12 (0 = no channel)

Select master channels of the zones (lowest numbered

channel in the zone) to exclude.

The zone subchannels follow the state of the master

channel.

Example: 3,5,12 = exludes channels with master channels

3, 5 and 12.

- Bypass zone: 0, or 1 to 12 (0 = no channel, example: 3,12)

Select master channels of the zones (lowest numbered

channel in the zone) to bypass, MAXIMUM 2 channels.

The zone subchannels follow the state of the master

channel.

Example: 4,12 = bypasses zones with master channels 4

and 12.

- Ceiling cooling channel: 0, or 1 to 12 (0 = no channel,

example: 1,4,10)

Select the channels which controls ceiling cooling in the

zones. The zone subchannels will not follow the state of the

master channel.

Example: 1,4,10 = set ceiling cooling to channels 1, 4 and

10.

Repeat for each Base PRO controller in the system.

Caution!

Do not remove the microSD card while the controller

is powered on.

Note

Make sure the correct slave address is set (between

1 and 247, unique for each controller in the system),

and that the other setting match the Modbus RTU

settings in the BMS.

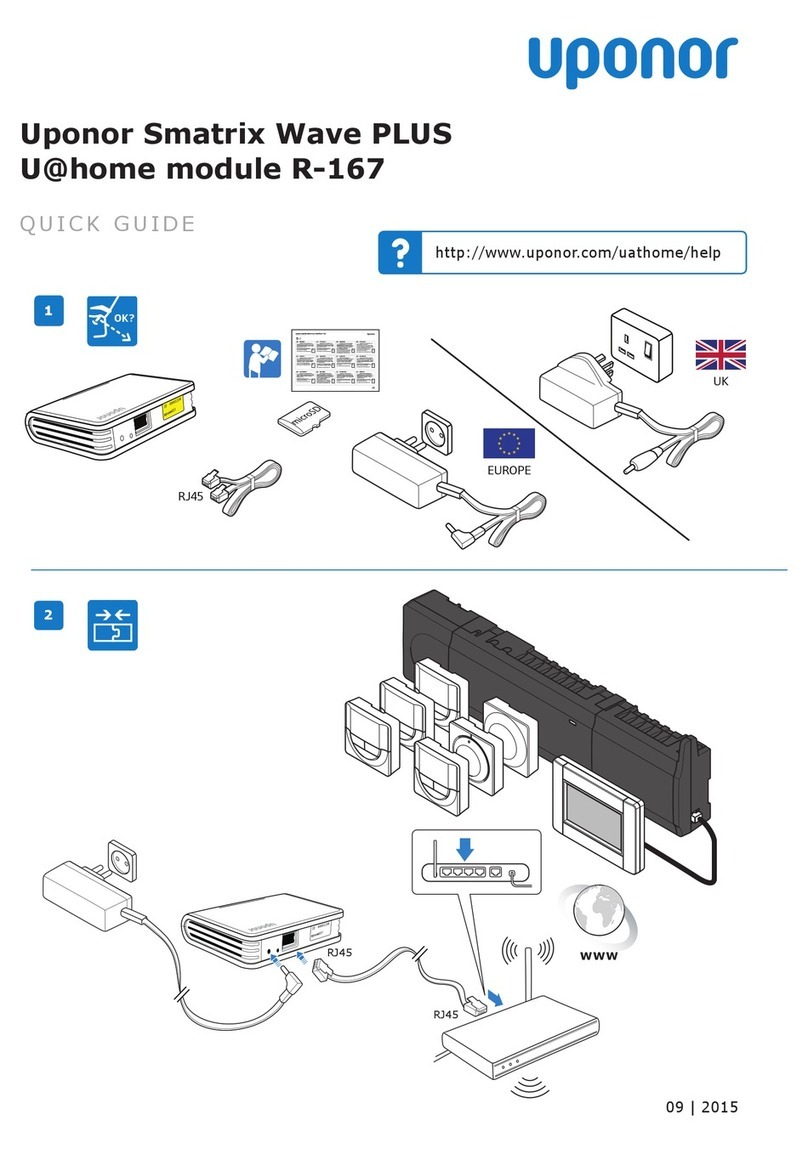

5. Connect the controllers to each other using the Base PRO

controller system device bus.

6. Connect the Base PRO system to the BMS.

All manuals and user guides at all-guides.com