Page 16 060570-008 MX15 / MX19 - Operator Manual

Specifications

S

PECIFICATIONS

*Specifications are subject to change without notice. Hot weather or heavy use may affect performance.

Refer to the Parts Manual and the Service Manual for complete parts and service information.

The MX15/19 meets or exceeds all applicable requirements of OSHA and ANSI A92.6-1999.

ITEM MX15 MX19

Platform Size (Inside minimum)

Standard w/Deck 0,72 m x 2,54 m (28.5 in. x 100 in.) 0,72 m x 2,54 m (28.5 in. x 100 in.)

Maximum Platform Capacity

Standard w/Deck Extension 250 kg (550 Lbs.) 227 kg (500 Lbs.)

Maximum Number of Occupants

Standard w/Deck Extension 2 People 2 People

on Extension 1 Person 1 Person

Height

Working Height 6,4 m (21 ft.) 7,62 m (25 ft.)

Maximum Platform Height 4,57 m (15 ft.) 5,8 m (19 ft.)

Maximum Drivable Height 4,57 m (15 ft.) 5,8 m (19 ft.)

Dimensions

Weight 1343 kg (2960 Lbs.) 1465 kg (3230 Lbs.)

Overall Width 760 mm (30 in.) 760 mm (30 in.)

Overall Height (Lowered) 1,89 m (74.5 in.) 2,01 m (79.25 in.)

Overall Length (Deck in) 1,75 m (68.75 in.) 1,75 m (68.75 in.)

Drive Speed

Platform Lowered 3,7 km/h (2.3 mph) 3,7 km/h (2.3 mph)

Platform Raised 1,0 km/h (0.62 mph) 1,0 km/h (0.62 mph)

Energy Source

24 V battery pack (4-220 A hour,

6 V batteries, min. wt. 26,3 kg [58 Lbs.]

each), 4 HP DC electric motor

24 V battery pack (4-220 A hour,

6 V batteries, min. wt. 26,3 kg [58 Lbs.]

each), 4 HP DC electric motor

System Voltage 24 V DC 24 V DC

Battery Charger 20 A, 110/220 VAC 20 A, 110/220 VAC

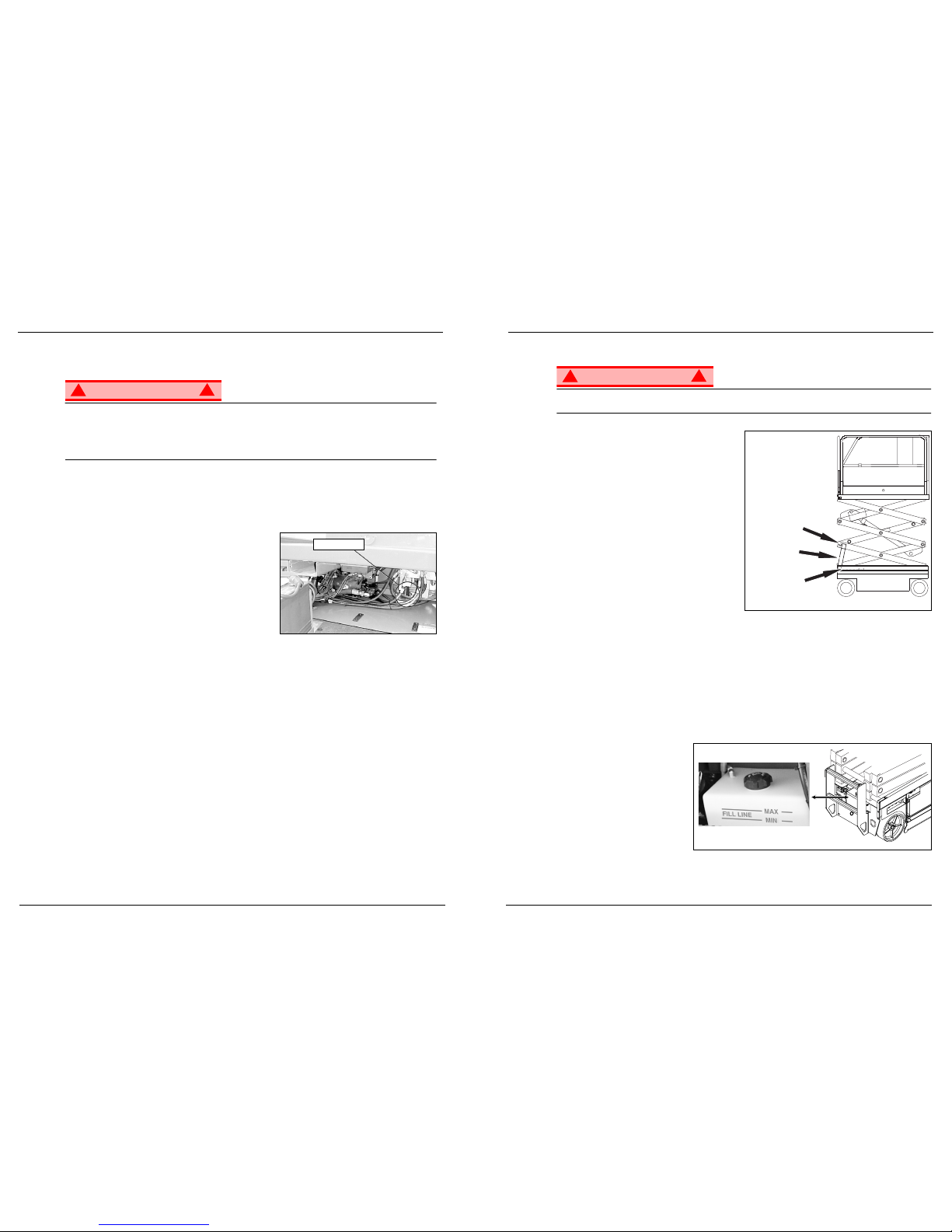

Hydraulic Reservoir Capacity 12,9 L (3.4 US gal.) 12,9 L (3.4 US gal.)

Maximum Hydraulic System Pressure 207 bar (3000 psi) 207 bar (3000 psi)

Hydraulic Fluid

Normal above 32° F [0° C] ISO #46 ISO #46

Low Temp. below 32° F [0° C] ISO #32 ISO #32

below 0° F [-17° C] ISO #15 ISO #15

Lift System One Single Stage Lift Cylinder One Single Stage Lift Cylinder

Drive Control Motor Control Motor Control

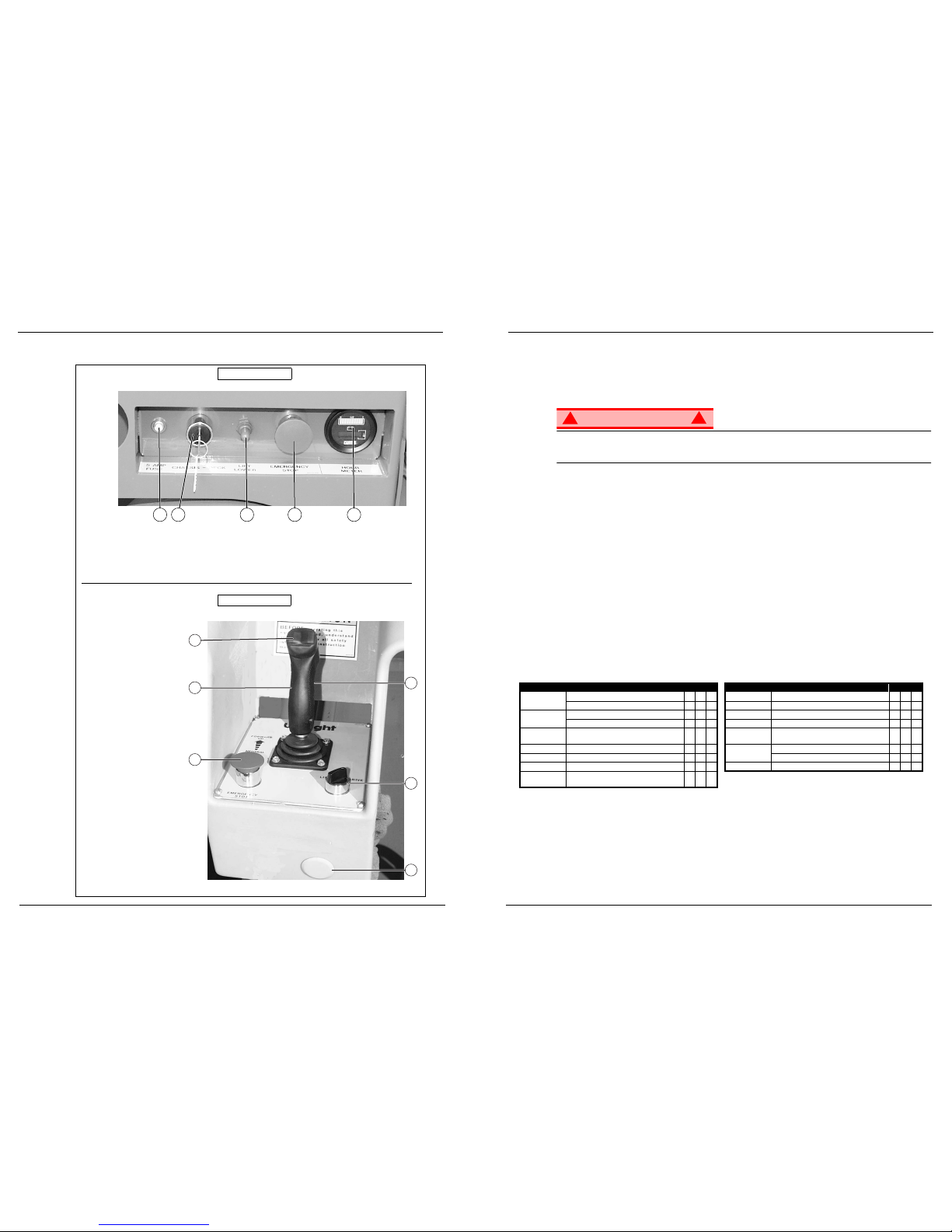

Control System

Control Handle with Interlock Switch,

Rotary Drive/Lift Switch, and Red

Mushroom Emergency Stop Switch

Control Handle with Interlock Switch,

Rotary Drive/Lift Switch, and Red

Mushroom Emergency Stop Switch

Drive System Dual Front Wheel Hydraulic Motors Dual Front Wheel Hydraulic Motors

Tires 30,5 cm (12 in.) diameter solid rubber,

Non-marking

30,5 cm (12 in.) diameter solid rubber,

Non-marking

Parking Brake Dual, Spring Applied, Hydraulic Release Dual, Spring Applied, Hydraulic Release

Turning Radius (inside) 150 mm (6 in.) Inside 150 mm (6 in.) Inside

Maximum Gradeability 29% (16°) 29% (16°)

Wheel Base 1,23 m (48.5 in.) 1,23 m (48.5 in.)

Guardrails 1,10 m (43 in.) 1,10 m (43 in.)

Toeboard 150 mm (6 in.) 150 mm (6 in.)

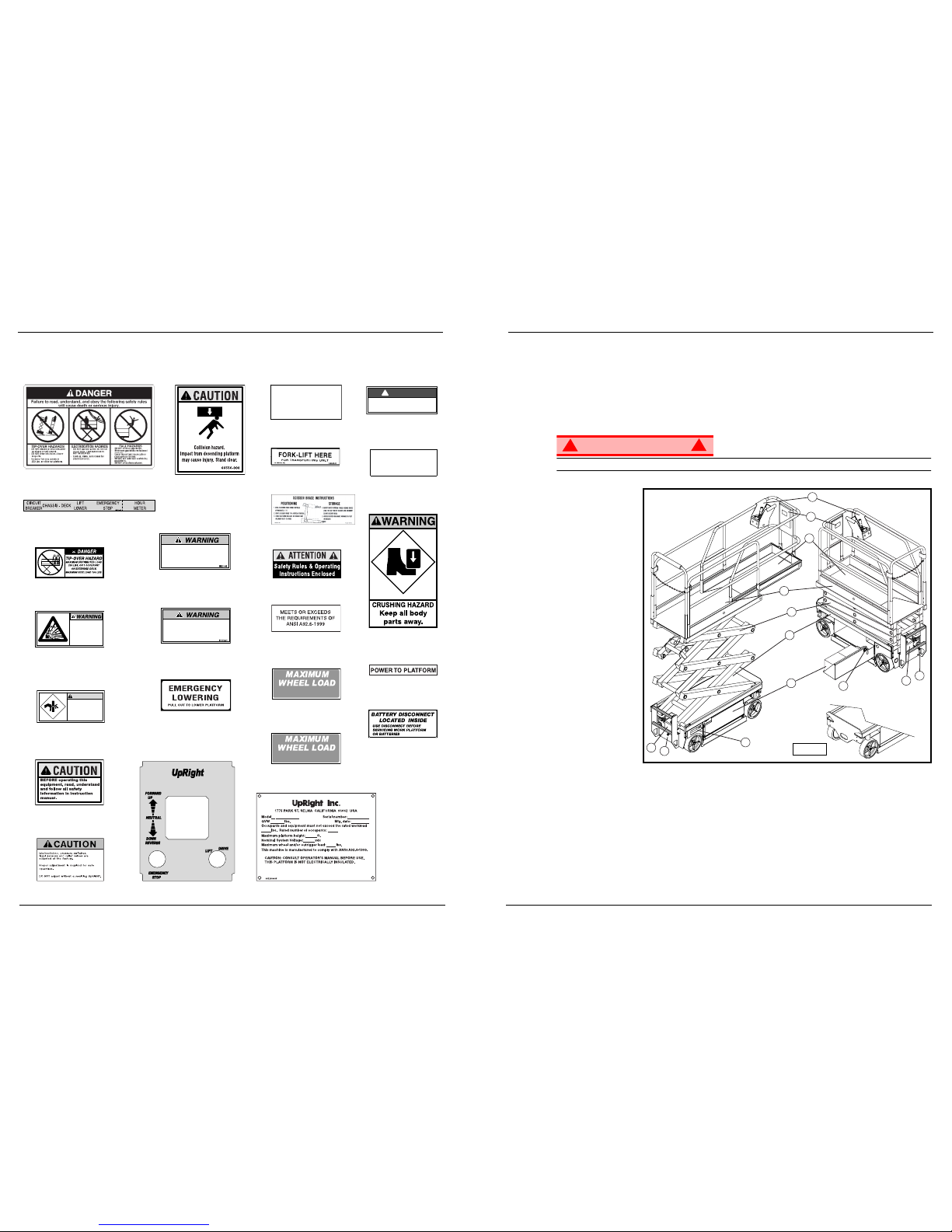

060570-008 MX15 / MX19 - Operator Manual Page 1

OPERATOR MANUAL

WARNING

All personnel shall carefully read, understand and follow all safety rules, operating instructions,

and the Scaffold Industry Association’s MANUAL OF RESPONSIBILITIES of ANSI A92.6-1999

before performing maintenance on or operating any UpRight Aerial Work Platform.

Safety Rules

Safety RulesSafety Rules

Safety Rules

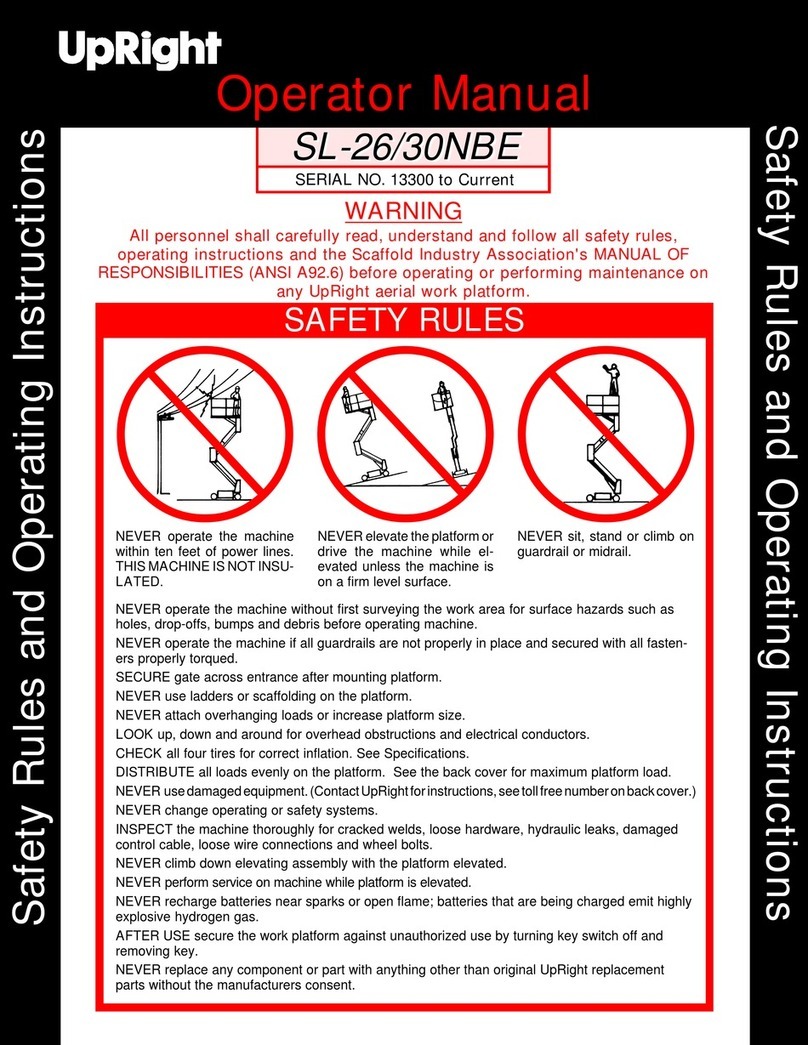

•NEVER operate the machine without first surveying the work area for surface hazards such as holes, drop-offs, bumps,

curbs, or debris.

•NEVER operate the machine if all guardrails are not properly in place and secured with all fasteners properly torqued.

•ALWAYS close and secure the entrance after entering the platform.

•NEVER use ladders or scaffolding on the platform.

•NEVER exceed the maximum platform load. See “Specifications” on page 16.

•NEVER attach overhanging loads or increase platform size.

•LOOK up, down and around for overhead obstructions and electrical conductors.

•DISTRIBUTE all platform loads evenly on the platform.

•NEVER use damaged equipment. (Contact UpRight for instructions. See toll free phone number on inside back cover.)

•NEVER change operating or safety systems.

•INSPECT the machine thoroughly for cracked welds, loose or missing hardware, hydraulic leaks, damaged cables or

hoses, loose wire connections, and wheel bolts.

•NEVER climb down elevating assembly when the platform is elevated.

•IF ALARM SOUNDS while the platform is elevated, STOP, carefully lower the platform. Move the machine to a firm, level

surface.

•IN CASE OF EMERGENCY push the Emergency Stop button to cut power to all machine functions.

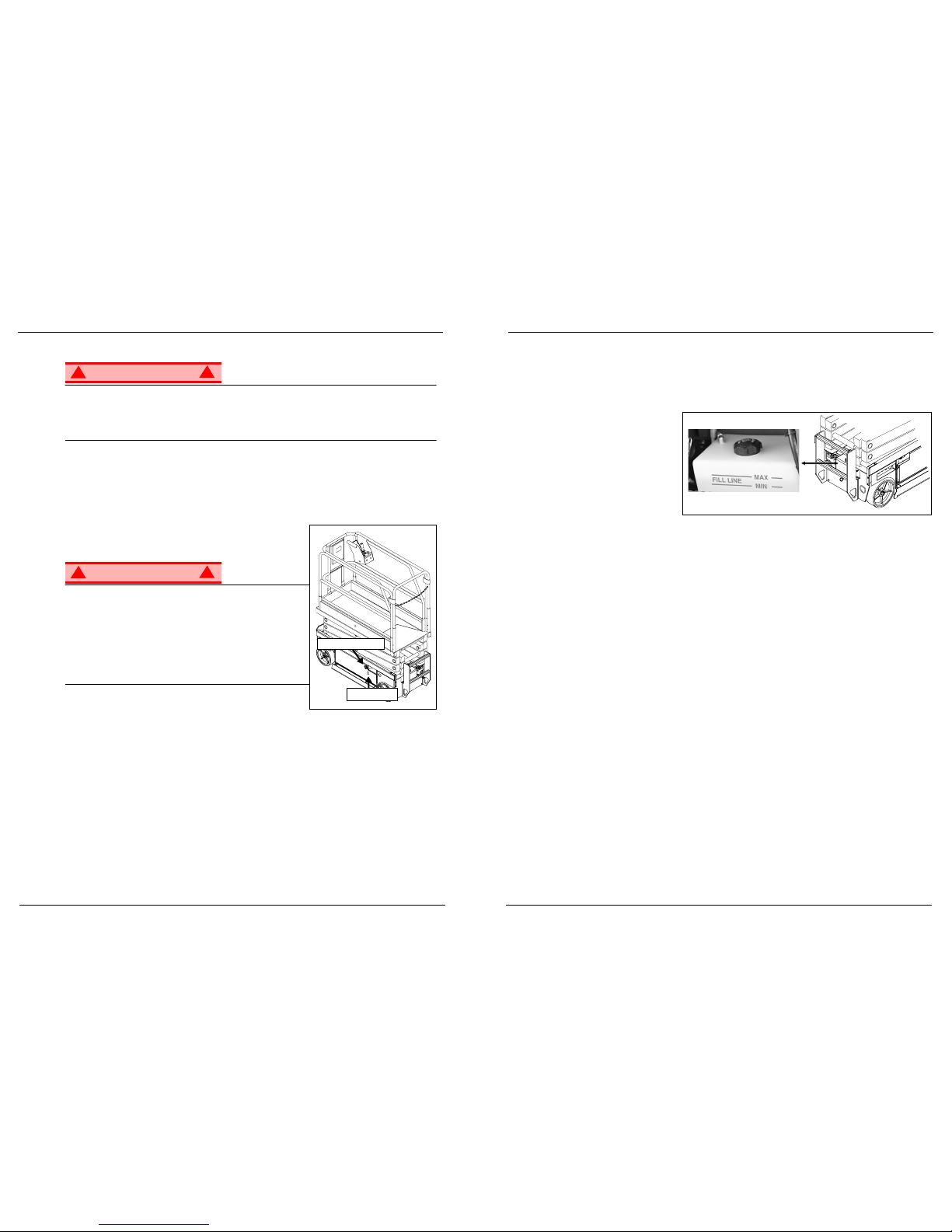

•NEVER perform service on the machine while the platform is elevated without blocking the elevating assembly.

•NEVER recharge batteries near sparks or open flame; batteries that are being charged emit explosive hydrogen gas.

•NEVER replace any component or part with anything other than original UpRight replacement parts without the manufac-

turer’s written consent.

•VERIFY that all labels are in place and legible before using.

•NEVER tow the machine. Transport by truck or trailer only.

•AFTER USE, secure the machine against unauthorized use by turning the key switch off and removing the key.

California Proposition 65 Warning

Gasoline and diesel engine exhaust and some of their constituents are known to the State of California to

cause cancer, birth defects, and other reproductive harm.

Battery Posts, terminals and related accessories contain lead compounds, chemicals known to the State of

California to cause cancer and reproductive harm. Wash hands after handling.

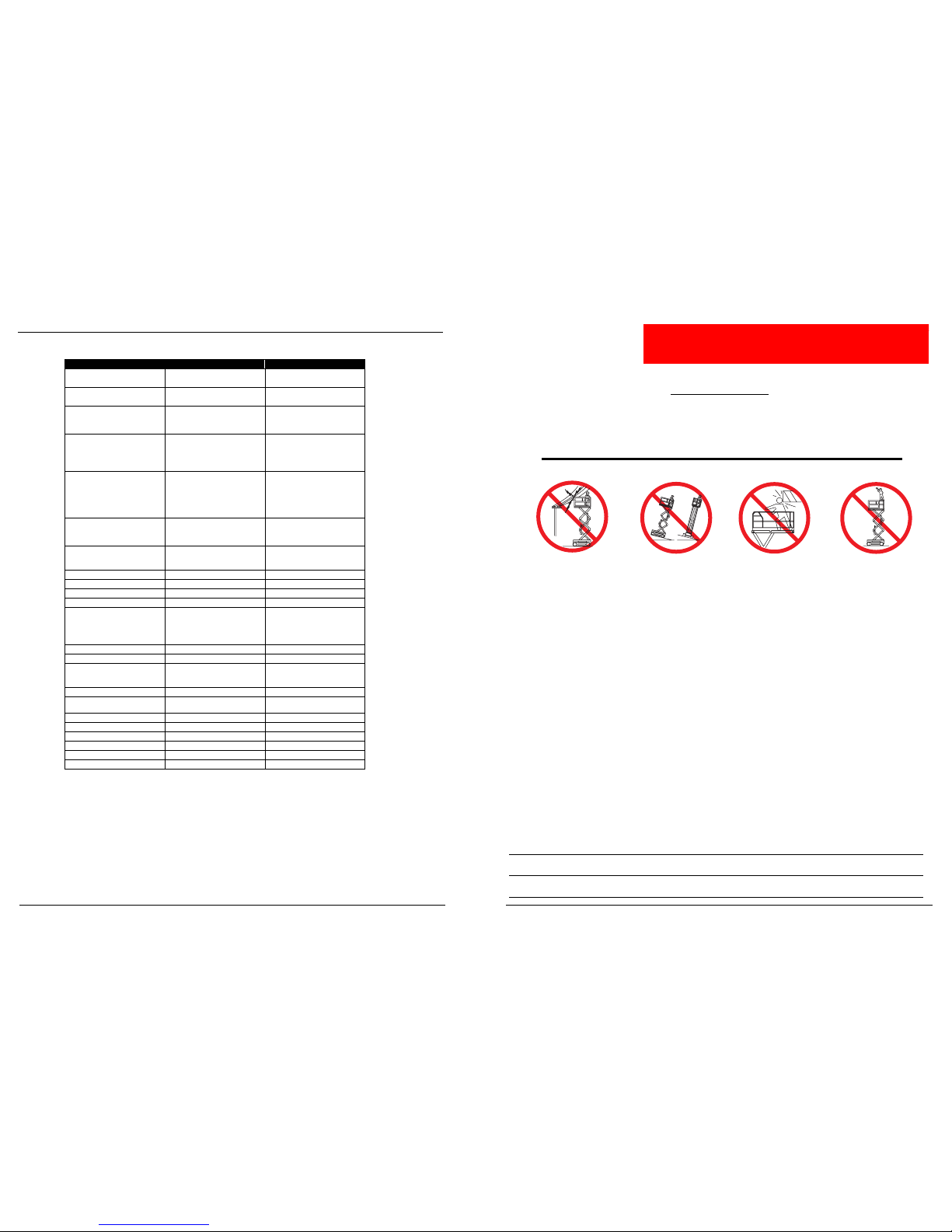

NEVER operate or drive with the

platform elevated unless on firm, level

surface.

NEVER position the platform without

first checking for overhead obstructions

or other hazards.

NEVER climb, stand or sit on the

platform guardrails or midrail.

Electrocution Hazard

Electrocution HazardElectrocution Hazard

Electrocution Hazard Tip Over Hazard

Tip Over HazardTip Over Hazard

Tip Over Hazard Collision Hazard

Collision HazardCollision Hazard

Collision Hazard Fall Hazard

Fall HazardFall Hazard

Fall Hazard

NEVER operate the machine within ten

(10) feet of power lines.

THIS MACHINE IS NOT INSULATED.