lArticle numbers,documentation

The serial number allows you to access the delivery data of the

instrument via www.vega.com,"VEGA Tools"and "serial number

search".

3.2Principle of operation

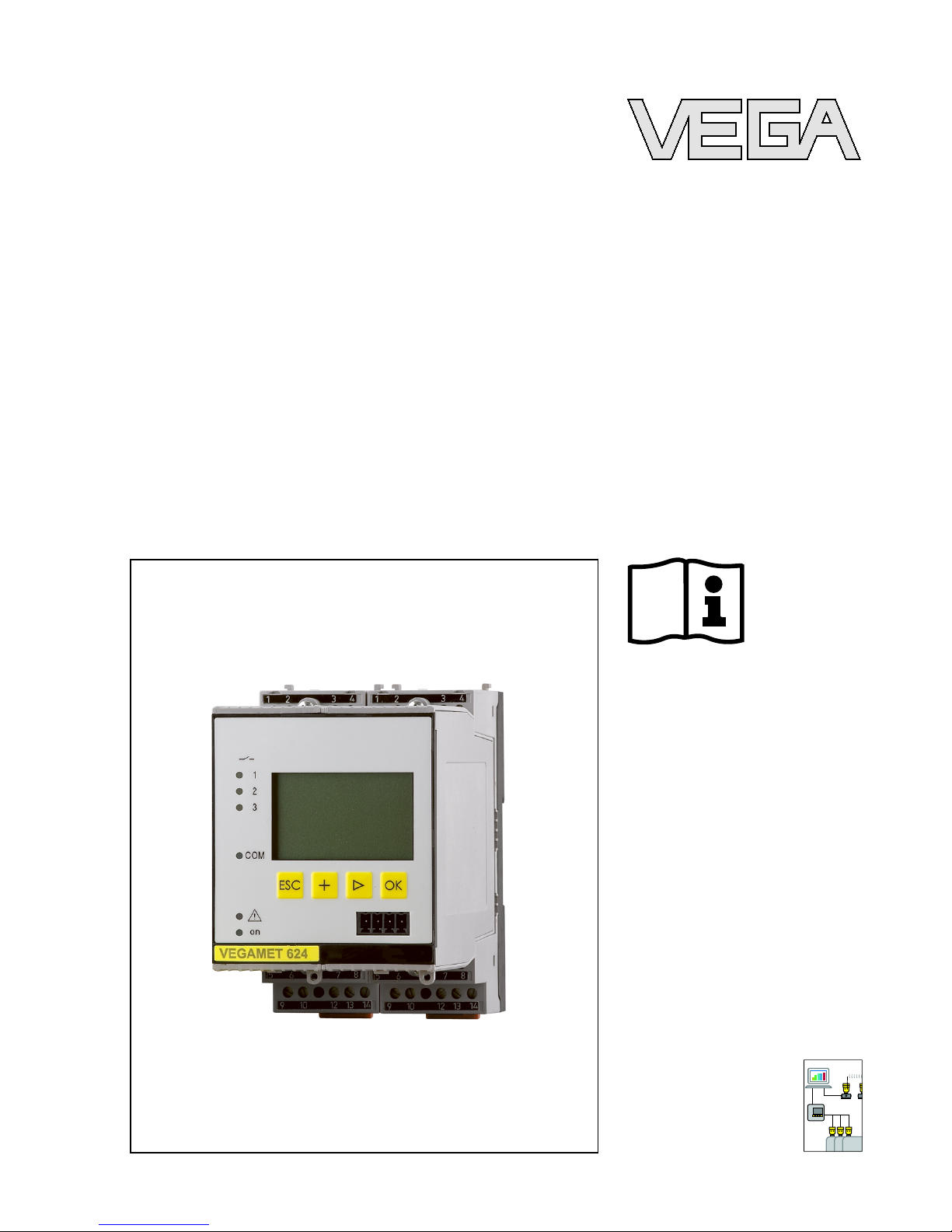

VEGAMET 624 is a universal signal conditioning instrument for a

number of applications such as level,gauge and process pressure

measurement.At the same time,it can serve as power supply unit for

connected sensors.VEGAMET 624 is designed for connection of any

4…20 mA/HART sensor.

On instruments with one of the optional interfaces (RS232/Ethernet),

the measured values can be retrieved via modem or network and

displayed by means of a web browser or WEB-VV.It is also possible to

send measured values and messages via e-mail/SMS.The use of

VEGAMET 624 is particularly suitable for stocktaking,VMI (Vendor

Managed Inventory)and remote enquiry.

The VEGAMET 624 signal conditioning instrument can power

connected sensors and process their measured signals.The

requested parameter is displayed and also sent to the integrated

current outputs for further processing.Hence the measured signal can

be transferred to a remote indicating unit or a superordinate control

system.Three level relays for control of pumps or other actuators are

also integrated.

Wide-range power supply unit with 20 …253 V AC/DC for world-wide

use.

Detailed information about the power supply can be found in chapter

"Technical data".

3.3Operation

The instrument can be adjusted with the following adjustment media:

lWith integrated indicating and adjustment unit

lan adjustment software according to FDT/DTM standard,e.g.

PACTware and a Windows PC

The entered parameters are generally saved in VEGAMET 624,when

used with PACTware and PC optionally also on the PC.

Information:

When using PACTware and the corresponding VEGA DTM,additional

settings can be carried out which are not or only partly possible with

the integrated indicating and adjustment unit.When using an adjust-

ment software,you either need one of the integrated interfaces

(RS232/Ethernet)or the interface converter VEGACONNECT.

Application area

Functional principle

Power supply

8VEGAMET 624 •4…20 mA/HART signal conditioning instrument

3Product description

28969-EN-091116