2

Contents

VEGABAR 82 • Modbus and Levelmaster protocol

46311-EN-160212

Contents

1 For your safety

1.1 Authorised personnel ....................................................................................................... 3

1.2 Appropriate use................................................................................................................ 3

1.3 Warning about incorrect use............................................................................................. 3

1.4 General safety instructions............................................................................................... 3

1.5 CE conformity................................................................................................................... 3

1.6 Permissible process pressure .......................................................................................... 4

1.7 NAMUR recommendations .............................................................................................. 4

1.8 Environmental instructions ............................................................................................... 4

2 Product description

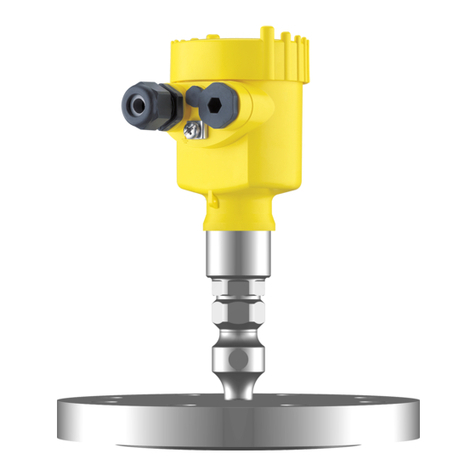

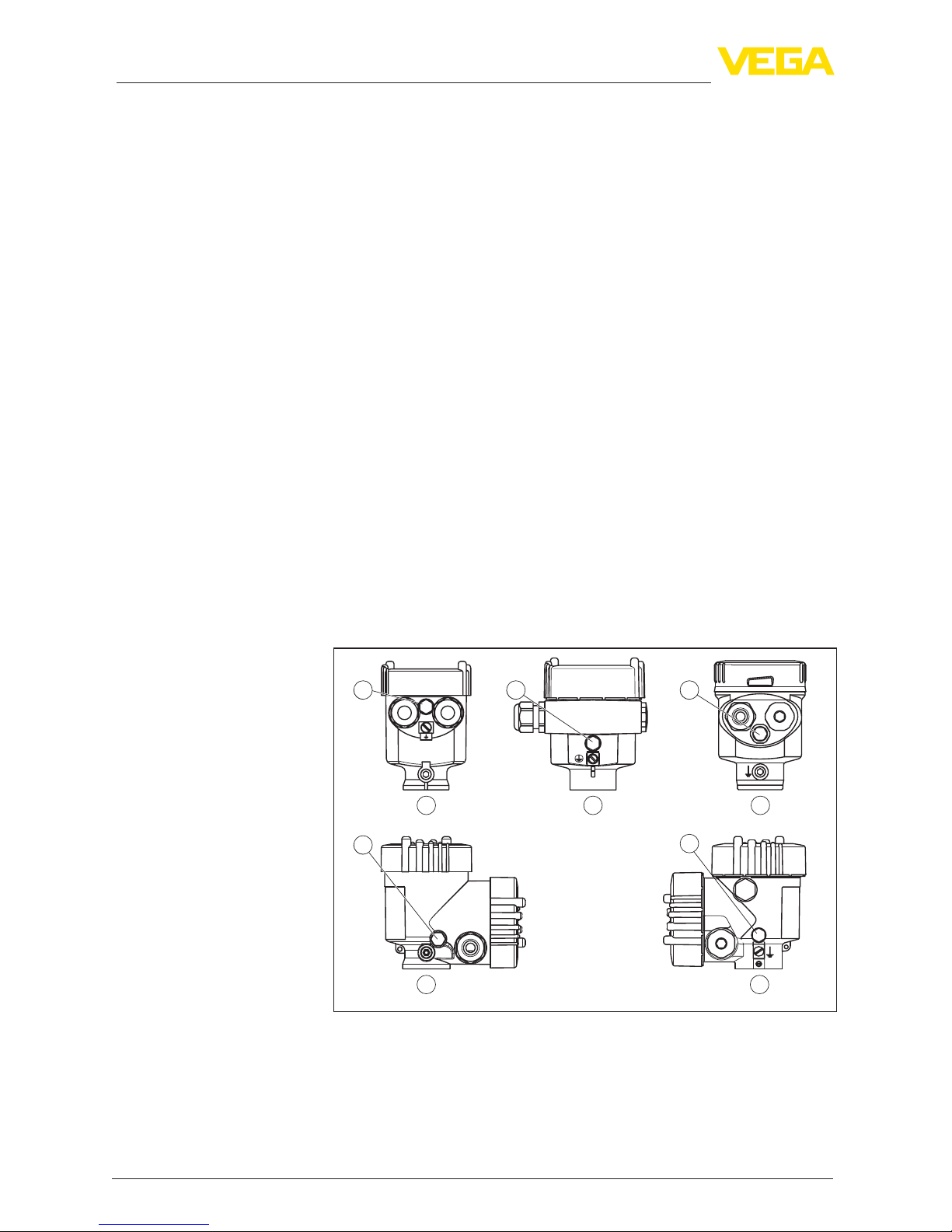

2.1 Conguration.................................................................................................................... 5

3 Mounting

3.1 General instructions for use of the instrument .................................................................. 6

3.2 Ventilation and pressure compensation............................................................................ 6

4 Connecting to power supply and bus system

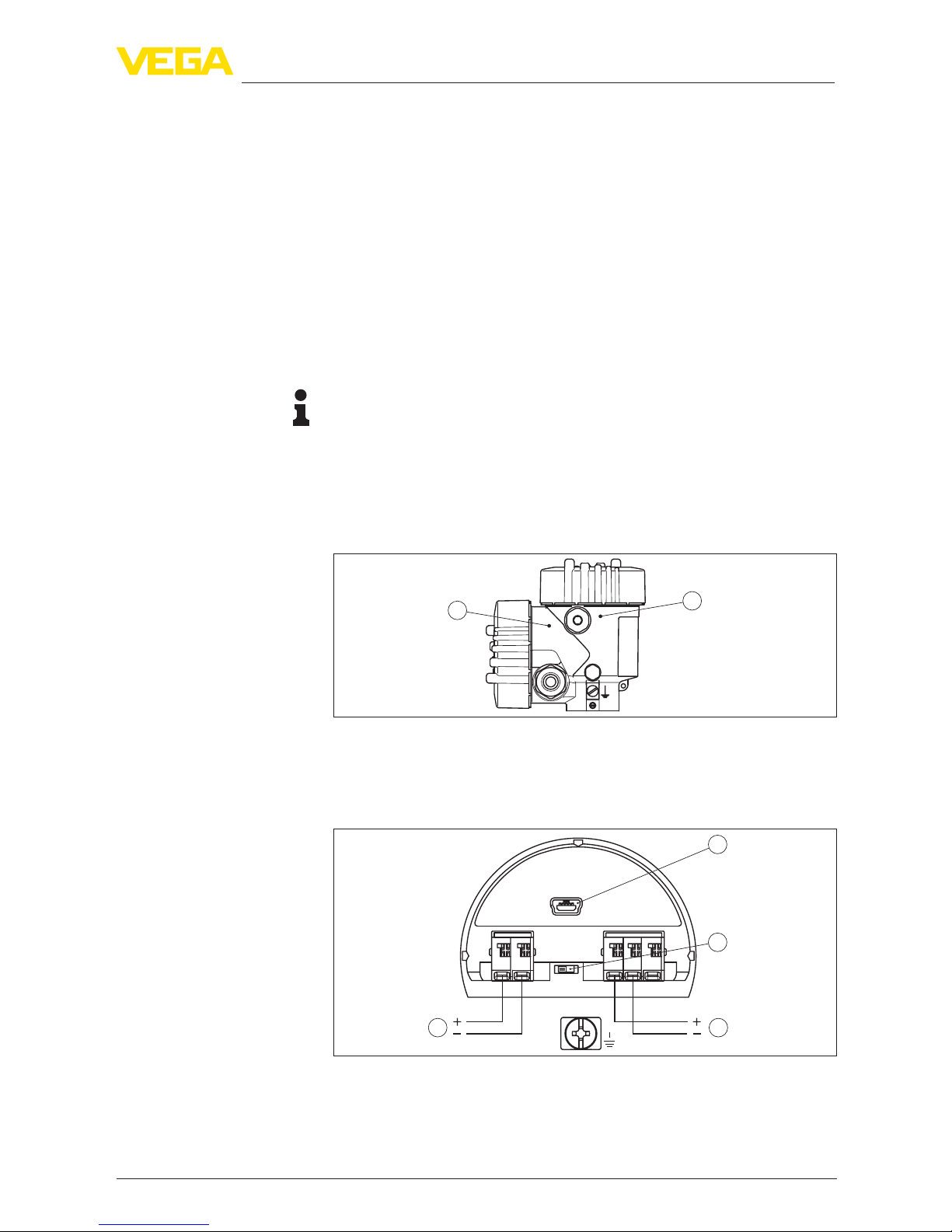

4.1 Connection....................................................................................................................... 8

4.2 Wiring plan ....................................................................................................................... 9

5 Set up the sensor with the display and adjustment module

5.1 Insert display and adjustment module............................................................................ 11

5.2 Parameter adjustment - Quick setup .............................................................................. 11

5.3 Parameter adjustment - Extended adjustment................................................................ 13

6 Supplement

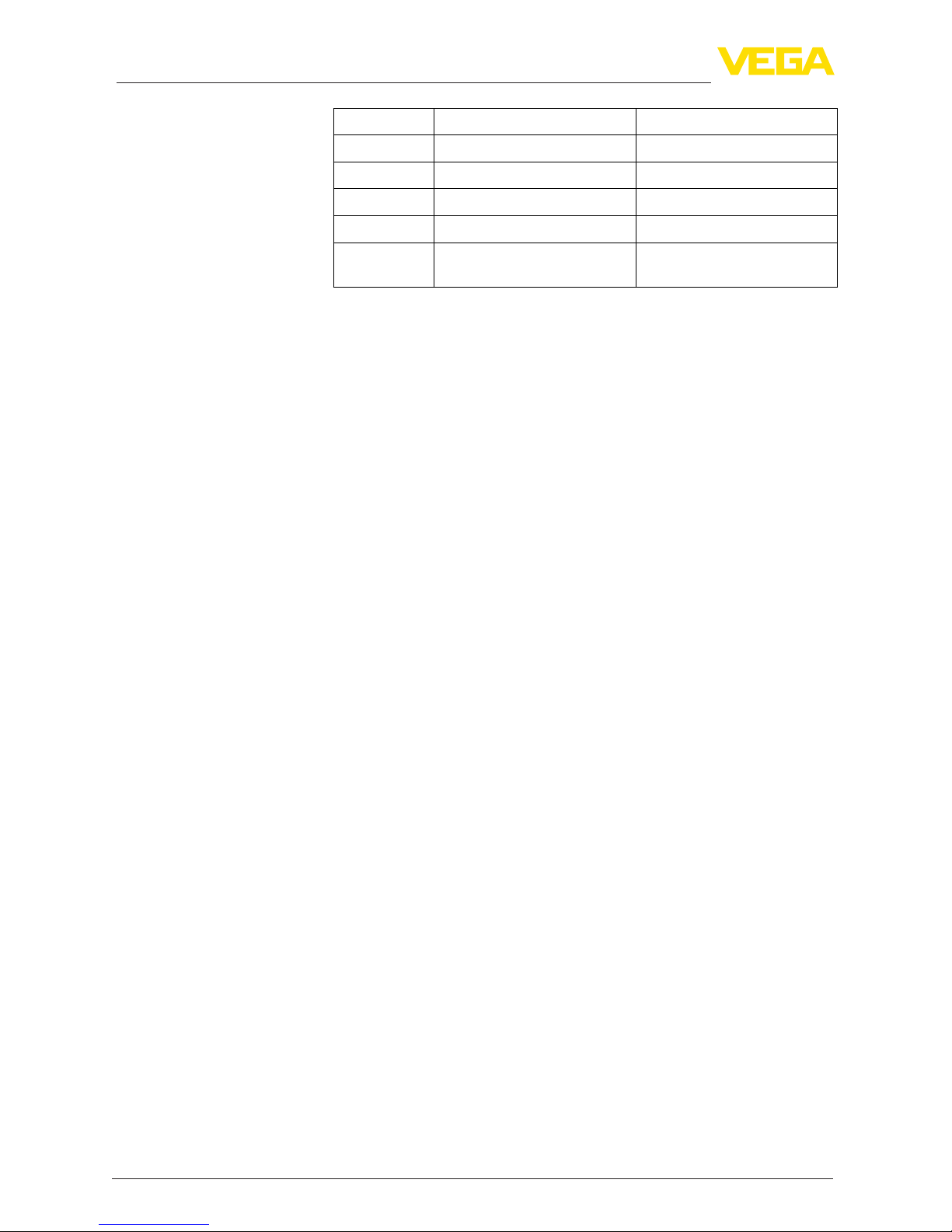

6.1 Technical data ................................................................................................................ 16

Information:

This quick setup guide enables quick setup and commissioning of

your instrument.

Youcanndsupplementaryinformationinthecorresponding,more

detailed Operating Instructions Manual as well as the Safety Manual

thatcomeswithinstrumentswithSILqualication.Thesemanualsare

available on the supplied DVD or in the download area of "www.vega.

com".

Operating instructions VEGABAR 82 - Modbus and Levelmaster

protocol: Document-ID 46294

Editing status of the quick setup guide: 2016-02-04