Contents

1About this document

1.1Function.................................. 5

1.2Target group .............................. 5

1.3Symbolism used............................ 5

2For your safety

2.1Authorised personnel ........................ 6

2.2Appropriate use ............................ 6

2.3Warning about misuse ....................... 6

2.4General safety instructions . . . . . . . . . . . . . . . . . . . . 6

2.5Safety label on the instrument . . . . . . . . . . . . . . . . . . 7

2.6CE conformity ............................. 7

2.7Fulfillment of NAMUR recommendations . . . . . . . . . . 7

2.8Safety instructions for Ex areas . . . . . . . . . . . . . . . . . 7

2.9Safety instructions for oxygen applications . . . . . . . . . 7

2.10 Environmental instructions..................... 7

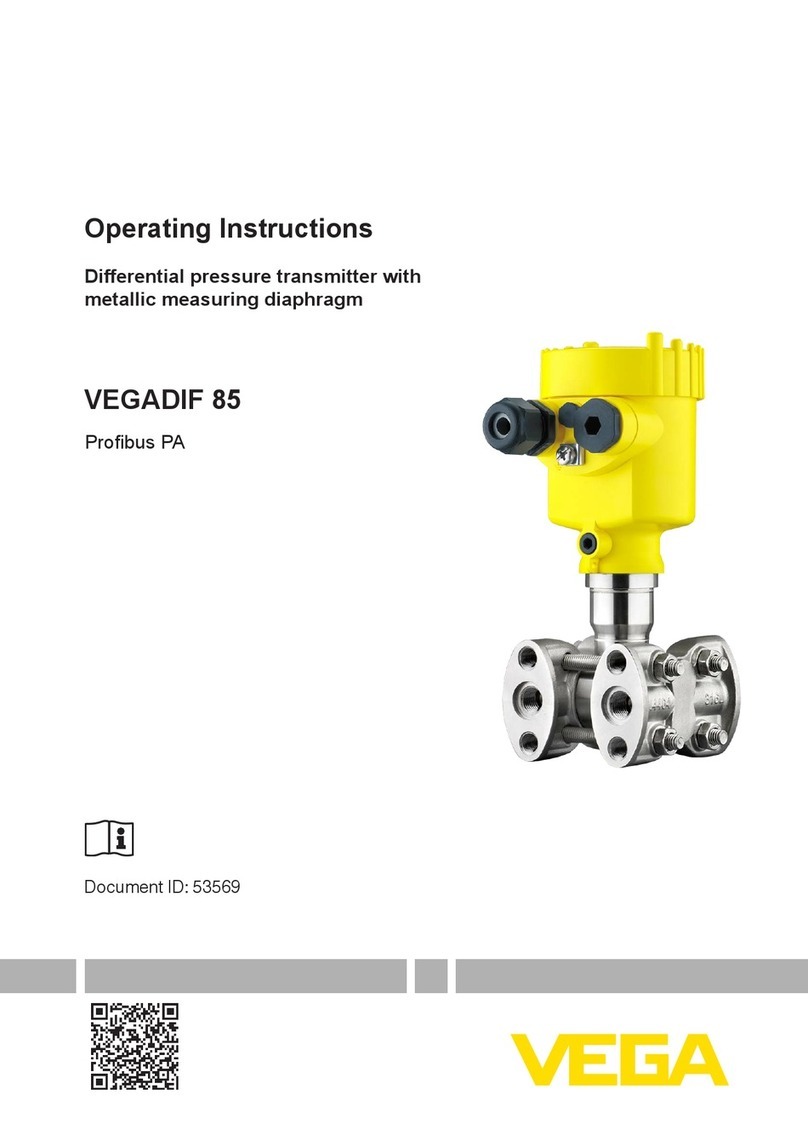

3Product description

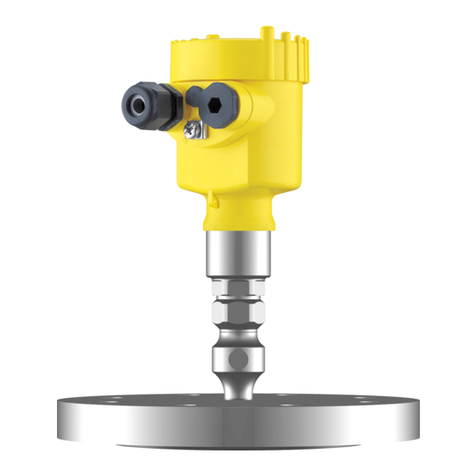

3.1Configuration .............................. 9

3.2Principle of operation ........................ 10

3.3Operation................................. 14

3.4Packaging,transport and storage ............... 14

4Mounting

4.1General instructions ......................... 16

4.2Special application conditions . . . . . . . . . . . . . . . . . . 17

4.3Flow measurement .......................... 18

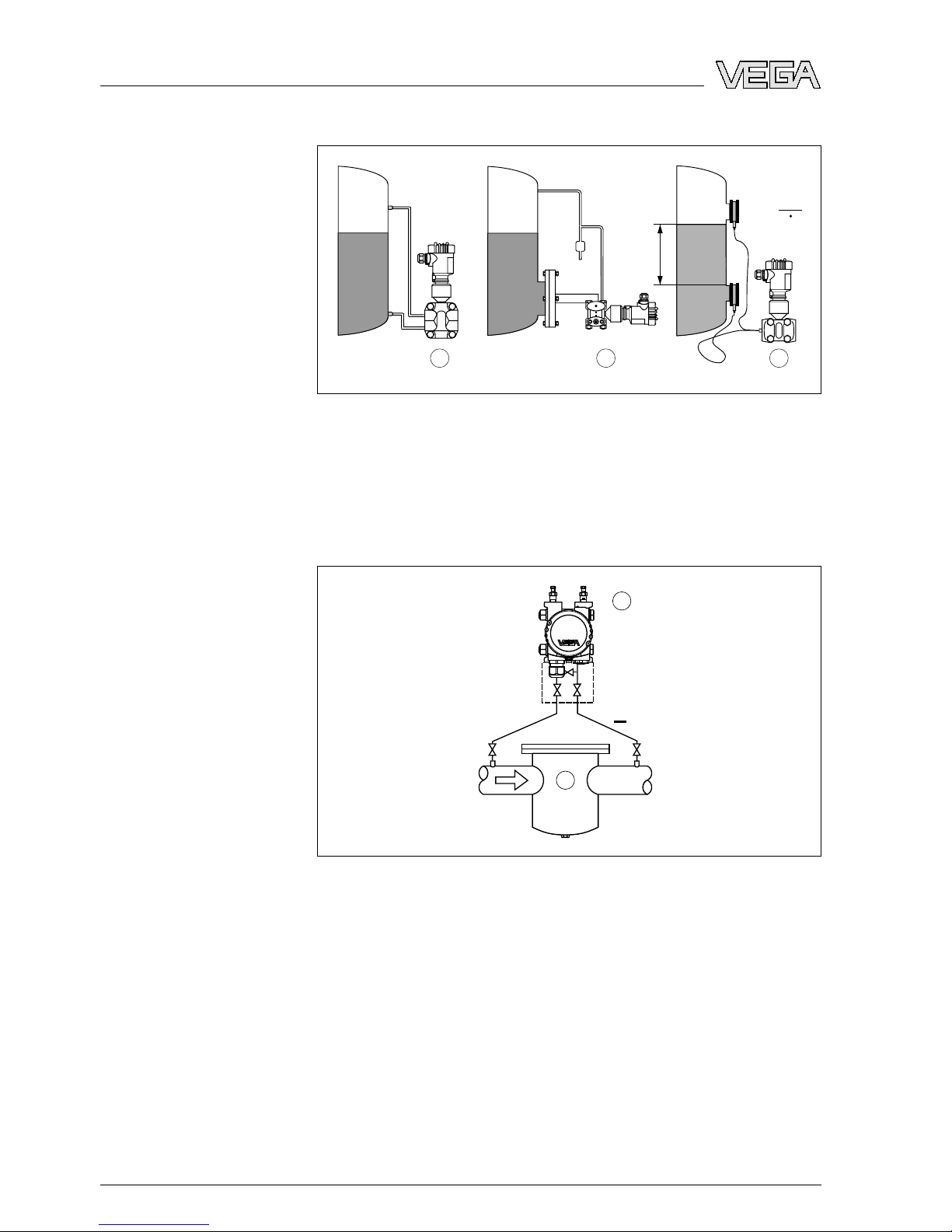

4.4Level measurement ......................... 20

4.5Density and interface measurement. . . . . . . . . . . . . . 25

4.6Differential pressure measurement............... 27

4.7Wall or tube mounting........................ 29

4.8External housing............................ 29

4.9Mounting control............................ 30

5Connect to power supply

5.1Prepare the connection....................... 31

5.2Connection procedure........................ 32

5.3Single chamber housing . . . . . . . . . . . . . . . . . . . . . . 35

5.4Double chamber housing ..................... 36

5.5Double chamber housing Ex d . . . . . . . . . . . . . . . . . 37

5.6Version IP 66/IP 68,1bar..................... 38

5.7External housing with version IP 68 . . . . . . . . . . . . . . 38

5.8Switch on phase............................ 39

6Adjustment with the indicating and adjustment module

PLICSCOM

6.1Short description ........................... 41

6.2Insert indicating and adjustment module. . . . . . . . . . . 41

6.3Adjustment system .......................... 43

2VEGADIF 65 •4…20 mA/HART

Contents

36128-EN-090604