2

This manual must be read in full before Installation, Operation and Maintenance of the units

supplied

Please ensure that this document is passed to the end user. This manual forms an integral part of

the product and should be kept for the working life of the product. Additional copies of this and

supporting documents are available by contacting VES or by visiting www.ves.co.uk and following

the 'Download O & M's' link.

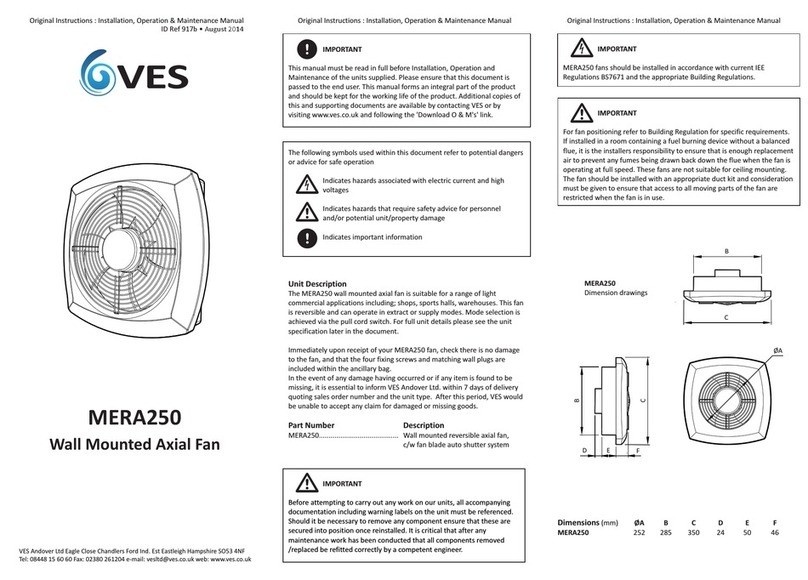

The following symbols used within this document refer to potential dangers, advice for safe

operation or important points of reference

Indicates hazards associated with electric current and high voltages

Indicates hazards that require safety advice for personnel or potential unit/property damage

Indicates important information

Warning

Caution

Important

Important

Conventions

roundfan inline centrifugal fans

page

Introducon .................................................................................................................................. 2

Nomenclature ................................................................................................................................ 3

Receipt of Goods & Handling ........................................................................................................

Installaon ......................................................................................................................................

Standard Wiring & Fan Installaon ........................................................................................... 6

1

2

3

4

5

6

Contents

Introducon

Maintenance .............................................................................................................................. 10

1

3

3

The roundfan series is a range of inline EC centrifugal fans available sizes from 100 mm to 315 mm

diameter, with a duty range up to 0.38 m³/s. The standard operang temperature for AC units is -25 to +45 °C

<95% RH.

For further technical details regarding dimensions and weights, contact VES on 02380 46 11 50, quong the

sales order (SO) number and the unit type as found on the unit nameplate, or alternavely visit

www.ves.co.uk.