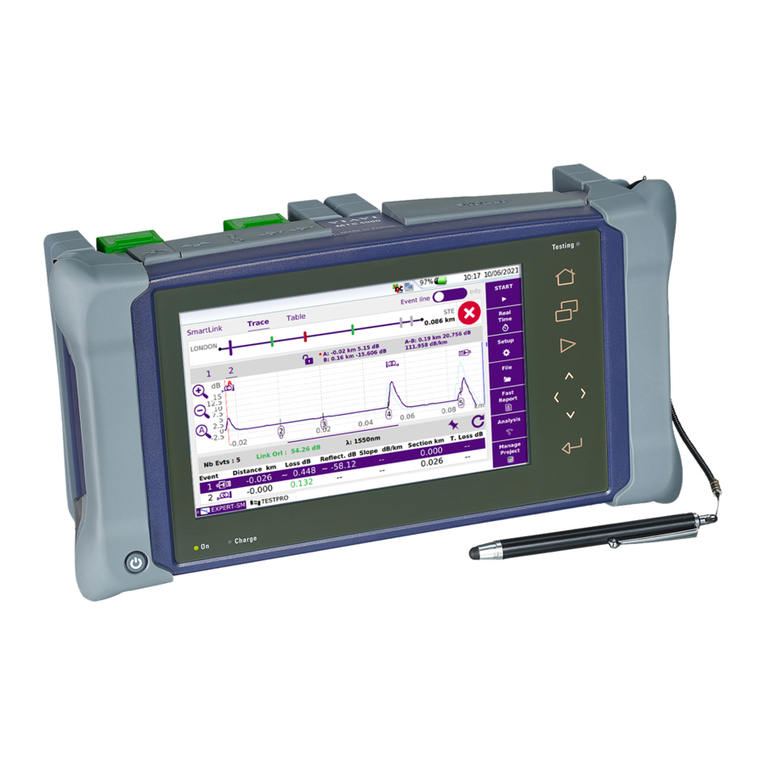

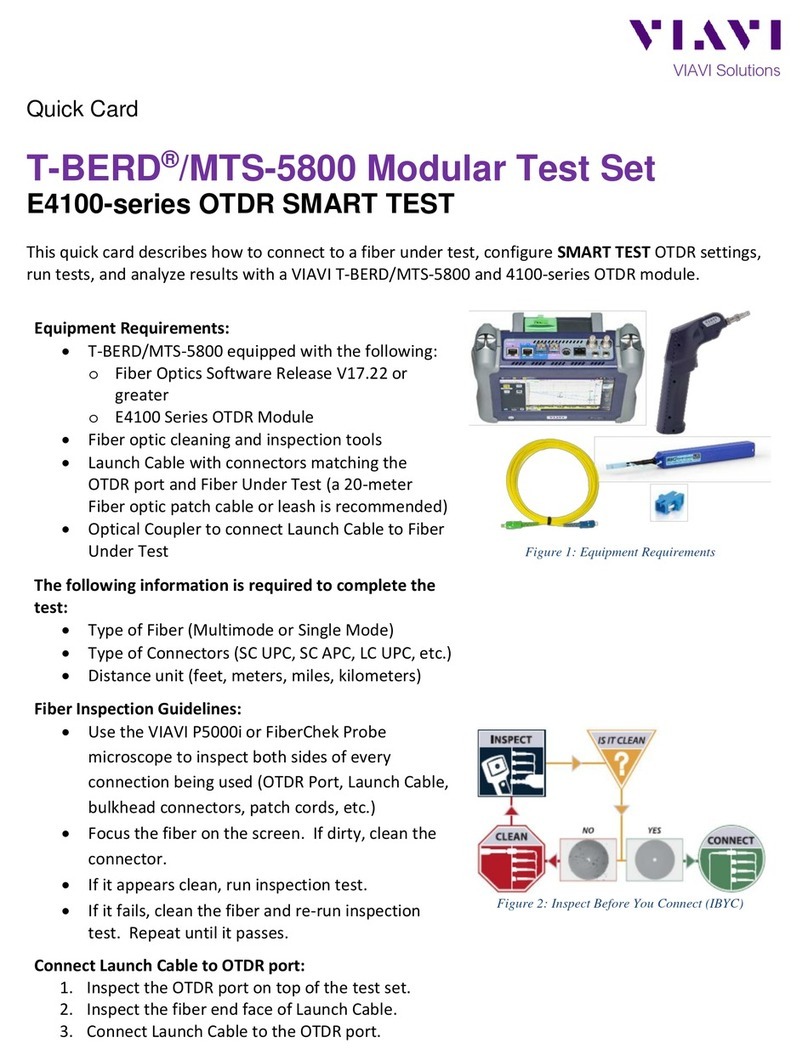

2000

15’’ Touchscreen

11

Direction keys & validation

2Charge indicator

12

Results

3On indicator

13

Loudspeaker

4File

14

Mini USB port

5Setup

15

AC/DC Input

6Start/Stop

16

Headset Jack

7Testing indicator

17

RJ45 connector

8On/Off

18

USB ports (2)

9Home

19

Power Meter port

10

Cancel

20

VFL or Talkset port

1

1312111098

765432

161514 19 201817

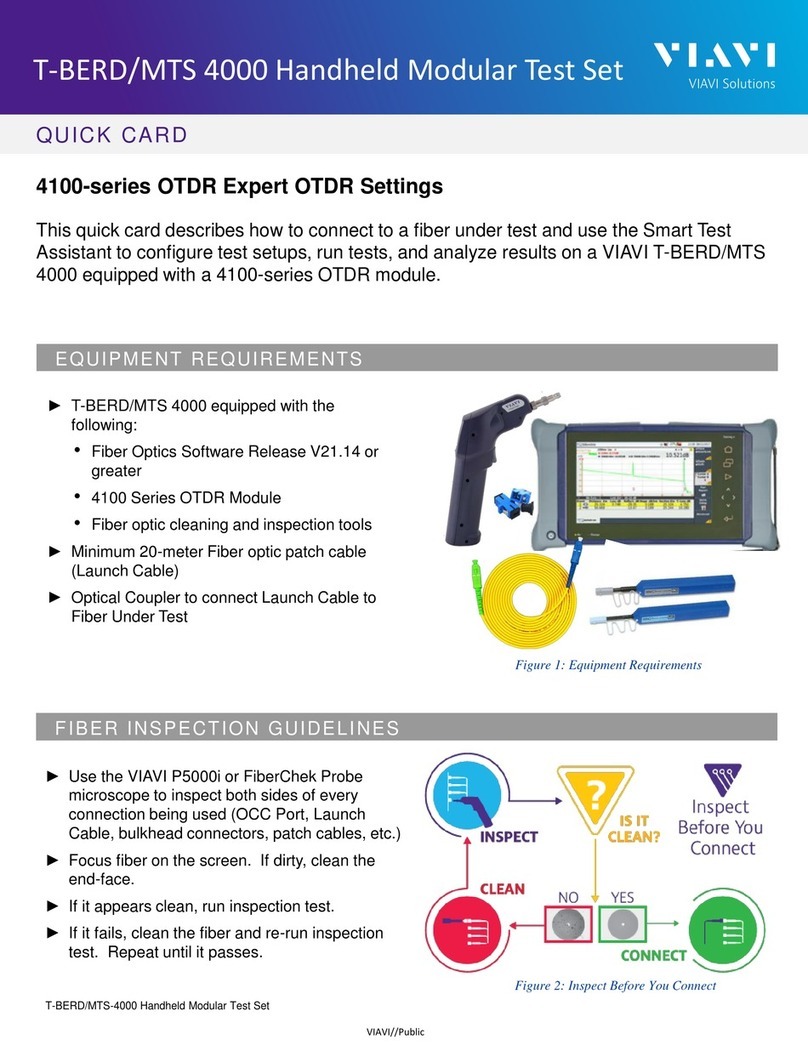

To access the User Manuals concerning the T-BERD/MTS-2000, go to the Home page and select

HELP icon. Click on one link in the WebBrowser page to open the correponding manual in PDF. You

can also transfer pdf files onto USB key (see «Transferring files - Through USB key»).

Press Cancel to deactivate a function selected.

MART TEST onfiguration File

3

Press Load Config. to select the right

configuration per your application and/or modify

the parameters.

1

On the Home page, select Smart TEST icon.

2

In the Results page, press SETUP hard key.

4

Select the configuration file corresponding to

your application and press Load as SMART

Config. key.

SETUP

summary of selected

configuration

To create a configuration file go in Expert mode (see «ExpertOTDR - Configuring Test / Creating

Smart config. File».

MART

1

Press RESULTS hard key to return to the

results page and press START/STOP button.

Step1: connector check

Step2: acquisition in progress

2

At the end of test,

the results trace displays.

START/STOP

1

Trace: select the active trace (multi-traces analysis)

Event: move the active cursor onto events

2

Zoom: zoom on trace

Shift: displace the displayed trace section

3

Select Cursor A and/or B

4

Allows to modify some acquisition parameters

before lauching a new OTDR test in Smart TEST

mode

5

Save in a sor file and create a txt or pdf report of

the results

6

Switch to Fault Locator view

1

2

3

4

5

6

T-BERD/MTS - 2000 GETTING STARTED MANUAL

Laser safety

The provisions contained in two standards define the safety procedures to be observed both by users

and by manufacturers when utilizing laser products:

-EN 60825-1: 2001 - Safety of laser products – Part 1: Classification of products, requirements and

user guidelines.

-FDA 21 CFR § 1040.10 - Performance standards for light-emitting products - Laser products.

Due to the range of possible wavelengths, power values and injection characteristics of a laser beam,

the risks inherent in its usage vary. The laser classes form groups representing different safety thresh-

olds.

-VFL option: Laser Class 2.

Due to the reduced dimensions of the optical modules, it is not possible to attach the required warning

labels to them. In line with the provisions of Article 5.1 of the EN 60825-1 standard, the laser class

identification labels are shown below:

Ref. standard EN 60825-1, Edition 1.2, 2001-08 FDA21CFR§1040.10

Class 2

LASER RADIATION

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

The user must take the necessary precautions concerning the optical outputs of the instrument and

follow the manufacturer’s instructions.

AC/DC power supply safety

Always use the proper adaptable plug to connect the power supply to an electrical outlet.

Viavi is not responsible for direct or indirect damage including damage to persons or property

if the power supply is not use correctly. For assistance using one of the Viavi supplied adapt-

ers (your specific regional adapter may not be available) please refer to the user manual.

!

CAUTION

LASER RAD

IATION - DO NOT STARE

INTO BEAM

CLASS II LASER PRODUCT

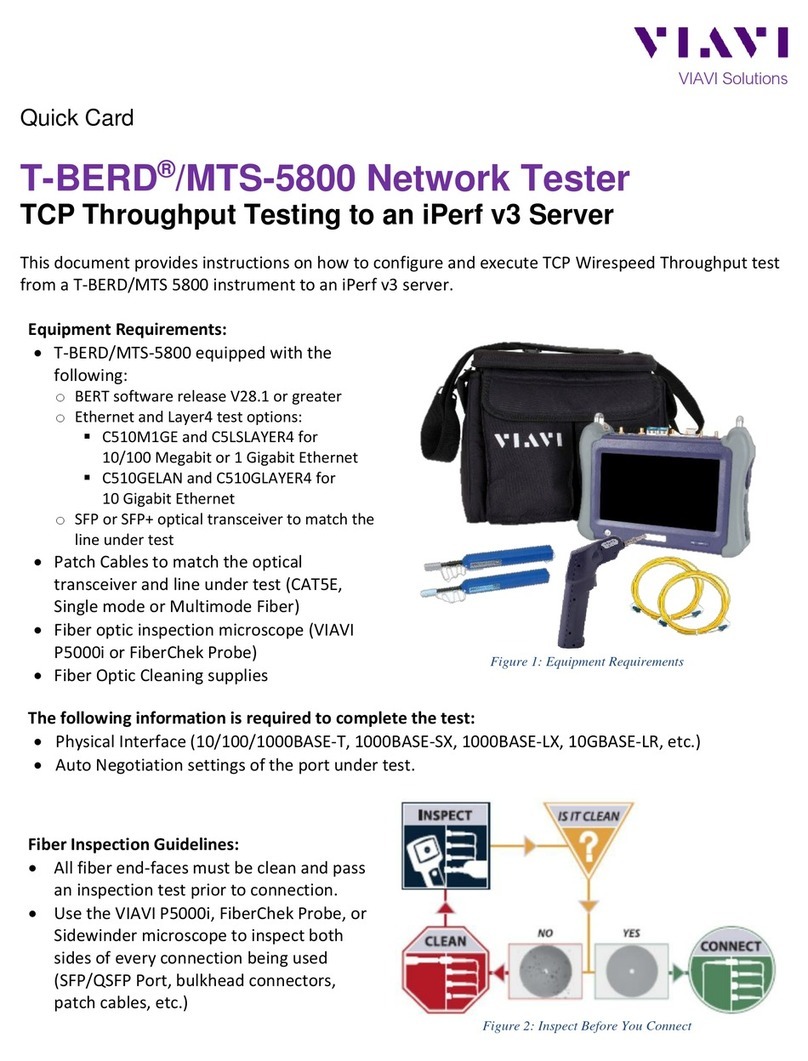

Before connecting a fiber into a test module, inspect and clean the module bulkhead and the fiber

jumper connectors.

1

Use a video inspection scope (such as P5000i) to verify the connector quality. Follow this simple

“INSPECT BEFORE YOU CONNECT” process.

2

Use appropriate cleaning material (e.g. IBC™ cleaner, cotton swab, dust air sprays, etc...) and

re-inspect to confirm.

3

Carefully align the connector and test port prior to mating both.

Never force the connector ferrule or insert it with an angle into the test port adapter. Mechanical

stress may permanently damage the ceramic sleeve of the adapter or the end face of the connector.

2000

2

On the Home page, select the Scope icon.

3

Use Focus control button on Scope to adjust

focus.

4

Configure the test of the connector.

7

A summary of test results is displayed:

Zones: A - Core / B - Cladding / C - Epoxy /

D - Ferrule

1

Connect the Scope to the 2000 Platform USB

port.

SETUP

5

Press

RESULTS

to return to Results page.

Configure the file storage

6