1

CONTENTS

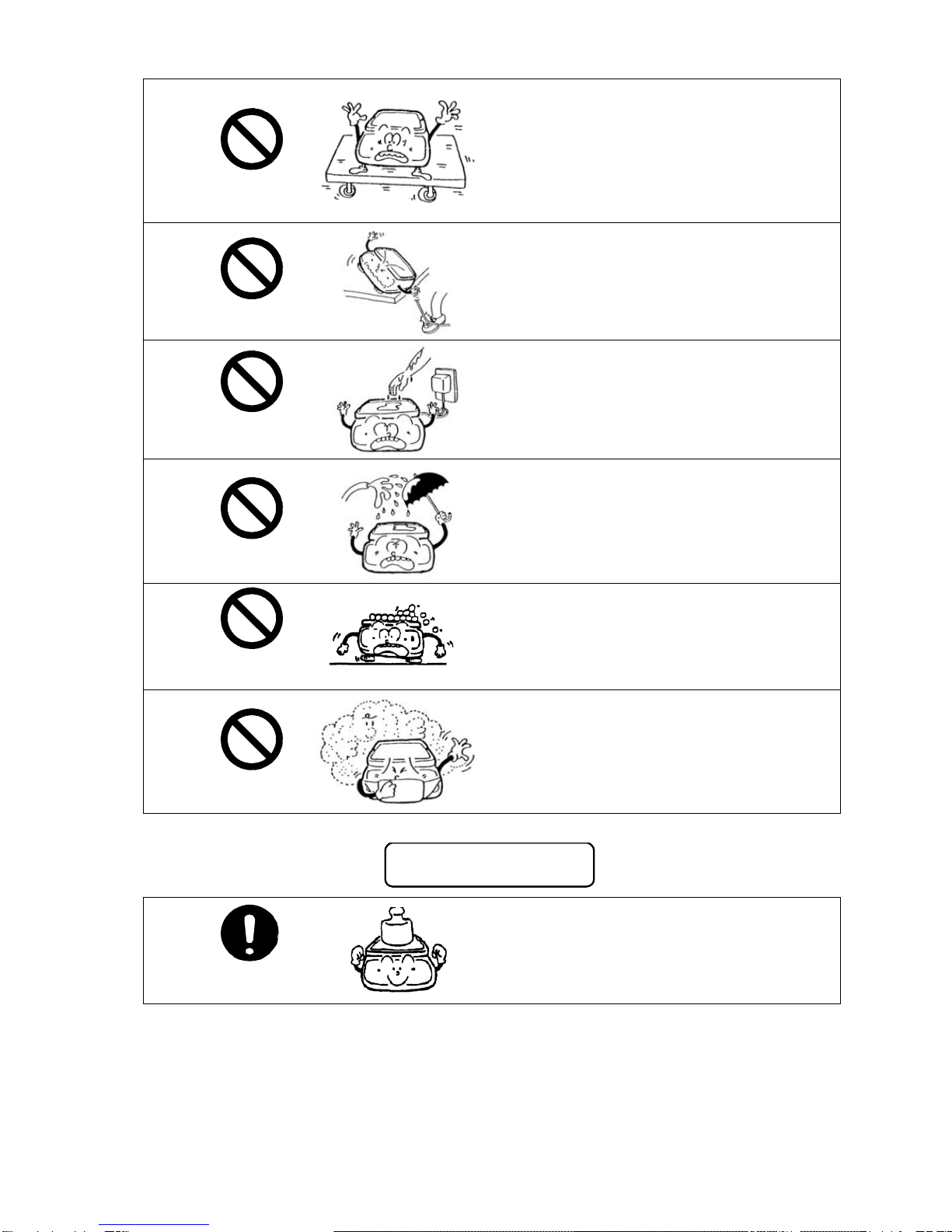

1. Precautions Relating on the Use........2

2. Specifications .....................................5

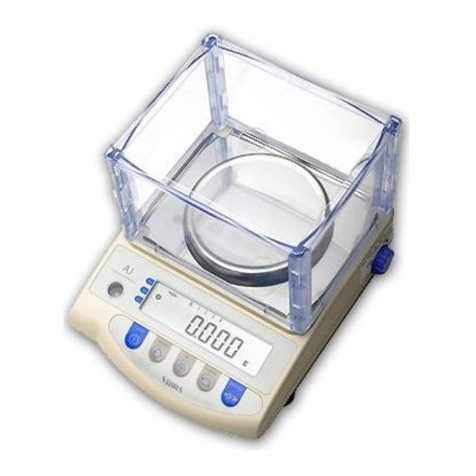

3. Names of Component Parts...............6

4. Installation ..........................................9

5. Operation Check...............................12

6. Time and Date Setup........................13

6.1 Time Setup..............................13

6.2 Date Setup..............................14

7. Calibration of Balance ......................15

7.1 Advice CAL.............................15

7.2 Span Adjustment with Built-In

Weight (Auto-Span

Adjustment).............................15

7.3 Span Test with Built-In

Weight.....................................16

7.4 Span Adjustment with External

Weight.....................................17

7.5 Span Test with External

Weight.....................................18

8. Basic Operations of Balance............20

8.1 Operation for Tare Range .......20

8.2 Example ofApplication ...........20

8.3 Minimum Indication Switching

Function..................................21

8.4 Interval Function.....................23

8.5 Time Output Function .............24

8.6 Counting Mode .......................25

8.7 Percentage Mode....................27

8.8 Addition Mode.........................28

8.9 Density Mode..........................29

9. Functions of Function 1....................30

9.1 Description of Function 1........30

9.2 Functions in Density Mode .....31

9.3 Interfaces................................31

9.4 Description of Compliance with

ISO/GLP/GMP ........................32

9.5 Setup and Check of

Function 1...............................32

10. Functions of Function 2....................33

10.1 Description of Function 2........33

10.2 Setup of ID No. ......................33

10.3 Setup of Error of Weight in

Use..........................................34

10.4 Calibration of Built-in Weight...36

10.5 Use of Weight Error ................37

11. Using the Printer...............................38

11.1 Setting up the Printer..............38

11.2 Printing in Compliance with

ISO/GLP/GMP ........................38

11.3 Recording Calibration

Results....................................38

11.4 Outputting Measurement Data

in Compliance with

ISO/GLP/GMP ........................39

12. Input/Output Functions.....................40

12.1 RS232C Output.......................40

12.2 Output to Peripherals..............43

12.3 Type of Communication

Texts........................................44

12.4 Output Data.............................44

12.5 Other Output Data...................46

12.6 Control with Commands..........47

13. Output in Compliance with

ISO/GLP/GMP..................................52

14. Servicing of Balance.........................58

15. Conversion Table of Units.................59

16. Troubleshooting................................60

Page Page