- vii -

Contents

Preface .................................................................................................................................. i

IECEx CERTIFICATE/Korean Certificate Safety ................................................................. ii

EU-TYPE EXAMINATION CERTIFICATE............................................................................ ii

Important Notice.................................................................................................................. iv

How to use this document.................................................................................................... v

Contents ..............................................................................................................................vii

1 Prior to use.................................................................................................................... 1

1-1 Precautions ........................................................................................................................ 1

1-2 For more accurate measurement ..................................................................................... 4

1-2-1 Precautions related to measuring environment ................................................................ 4

1-2-2 Precautions related to measuring table ............................................................................ 5

1-2-3 Precautions related to a specimen ................................................................................... 5

1-2-4 Precautions related to the main unit of a scale ................................................................. 6

1-3 Check for the articles contained in the box....................................................................... 7

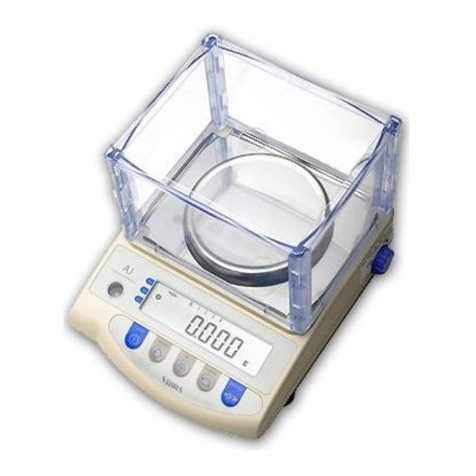

1-4 Name and function of each section .................................................................................. 8

1-5 Assembling and installation.............................................................................................. 9

1-5-1 How to mount the pole and the indicator ........................................................................ 11

1-5-2 Mounting of the pan base and the weighing pan ............................................................ 13

1-5-3 Mounting of the windshield (Option) ............................................................................... 14

1-5-4 Installation of the power supply box................................................................................ 15

1-5-5 Leveling .......................................................................................................................... 19

1-5-6 Grounding....................................................................................................................... 20

1-5-7 Connecting to main power supply and starting up .......................................................... 21

2 Maintenance ............................................................................................................... 22

2-1 Care and cleaning method ............................................................................................. 22

2-2 Care and cleaning method in the case of heavy soil ...................................................... 22

2-2-1 How to remove the side windshield (Square pan) .......................................................... 23

2-2-2 How to remove the side windshield (Round pan) ........................................................... 24

2-3 How to replace the fuse.................................................................................................. 26

2-4 Maintenance of earth connection ................................................................................... 26

2-5 Troubleshooting.............................................................................................................. 27

3 Repair ......................................................................................................................... 28

4 Taking out of service and dismantling......................................................................... 28

Appendix ............................................................................................................................ 29

Appendix 1 Specification .............................................................................................................. 29

Appendix 1-1 Metrological specification................................................................................... 29