EMEA SALES

2, rue Alexis de Tocqueville

92160 ANTONY

FRANCE

Phone +33 (0)1 55 59 10 25

Fax +33 (0)3 90 20 66 36

© 2007 RSI VIDEO TECHNOLOGIES™ Videoed®is a Registered Trademark of RSI VIDEO TECHNOLOGIES™.

S2View®is a registered trademark of RSI VIDEO TECHNOLOGIES™. Specications subject to change without notice.

USA SALES

4455 White Bear Parkway, Suite 700

White Bear Lake, MN 55110

USA

Phone 877-06-5800

Fax 651-762-4693

www.videofied.com

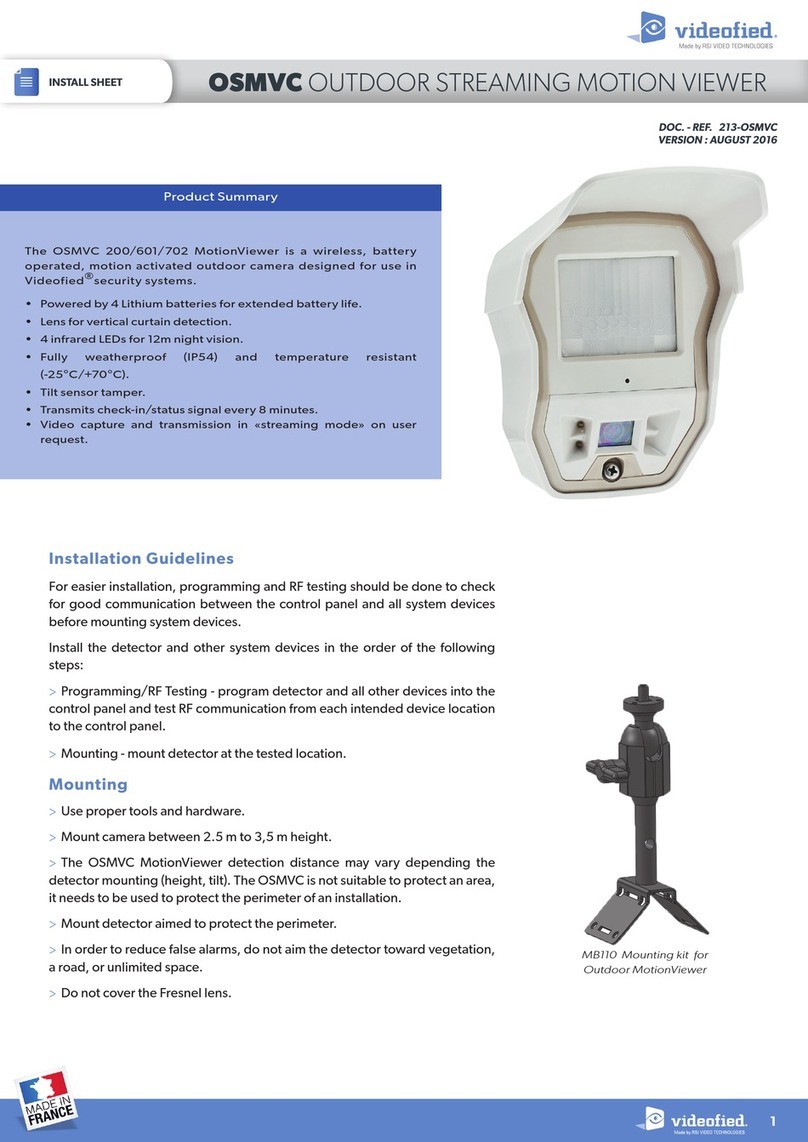

Mounting

> Use proper tools and hardware.

> Mount indoors in a temperature-controlled environment.

> Mount detector on frame and magnet assembly on movable

opening (door, window).

> When using internal switch, mount so that detector and

magnet alignment marks are lined up with each other.

> When using internal switch, do not exceed 3/8-inch/10 mm

gap between detector and magnet.

> Magnet spacers must be used to match magnet height with

detector to ensure correct alignment and functionality.

Regulatory Information

FCC Part 15

This device complies with FCC Rules Part 15.

Operation is subject to the following two conditions:

1.) This device may not cause harmful interference and,

2.) this device must accept any interference that may be received,

including interference that may cause undesired operation.

Changes or modications not expressly approved by RSI VIDEO

TECHNOLOGIES, Inc. can void the user’s authority to operate the

equipment.

Specifications

Panel Compatibility VIDEOFIED V6000/VISIO1000/V7000

Operating Frequency 915/868/920 MHz

Radio type Spread Spectrum Bidirectional RF

Power Requirements One 3.6 V lithium battery

Battery Type LS14500

Operating Temperature 32° - 104° F (0° - +40° C)

Maximum Relative Humidity 70% non-condensing

Dimensions (LxWxD) 3 in. x 1-3/8 in. x 1 in. / (80 mm x 35 mm x 23 mm)

Weight 1.4 oz. (40 g) without battery

Approvals UL / FCC (CT600/610)

CE / EN50131 / EN300220 / INCERT/ IDA / NCP (CT201/211)

A-Tick (CT700/710)

Note: If detector installation only requires use of the external input,

magnet assembly installation is not required.

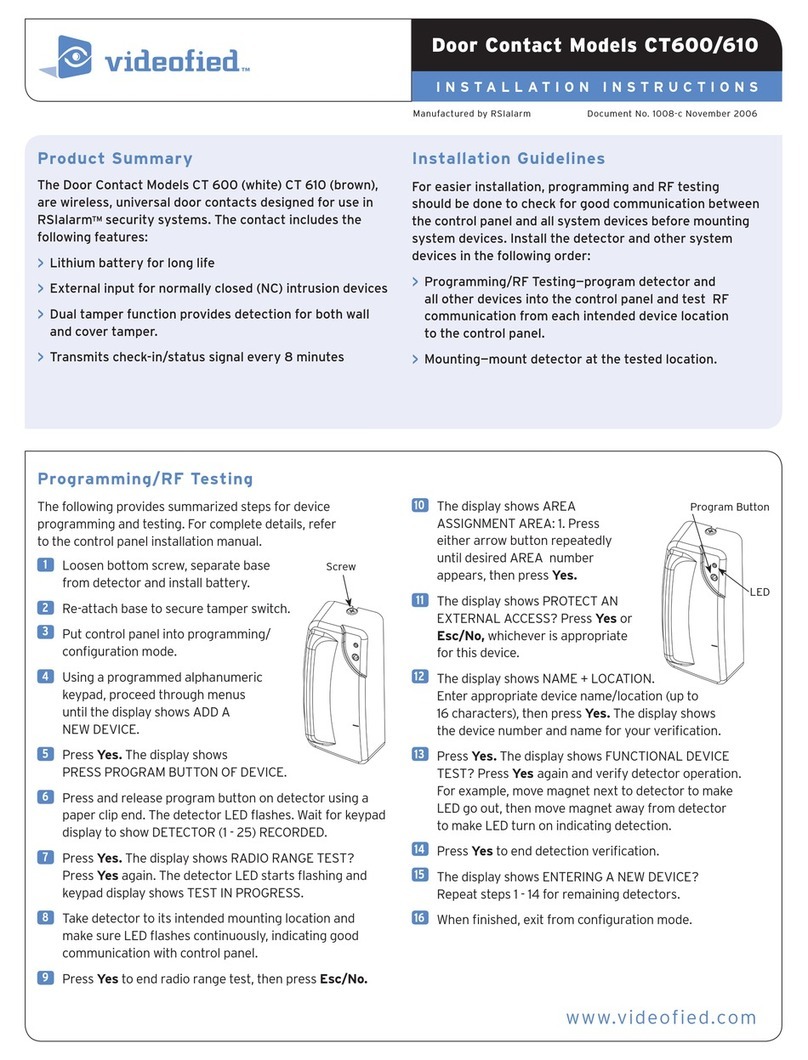

1Separate base from detector.

2Hold detector base against

mounting surface and mark

the two mounting holes.

3Drill pilot holes into mounting

surface.

4Mount detector base to surface

using appropriate screws.

5If using external input, run

2-conductor, 22-gauge wire from

protection point to detector.

6Connect hardwire circuit wires to

external input screw terminals.

7Connect other end of wires to

initiating device and install the

battery.

8Attach detector to base, making

sure every wire is secure with screws.

9Attach wedges to magnet holder

as needed to match height of detector.

10 Hold magnet base against

mounting surface and mark

the two mounting holes.

Note: Be sure alignment marks on detector

and magnet base are lined up with each other

and that there is no more than a 3/8-inch

(10 mm) gap between them.

11 Drill pilot holes into mounting surface.

12 Insert screws through magnet base and wedges,

then secure to mounting surface.

13 Attach cover to magnet holder.

External Input Terminal, Jumper position and wiring

Note: The internal jumper wire is only used for internal or external

switch use. The jumper is not used when both Int. and Ext switches

are used together. The default jumper position is in the Internal

switch mode. it only has to be changed if wiring external switches

to the transmitter.

The internal jumper shown in

position for possible connections.

1. Internal reed switch only

2. External reed switch only

3. Both Int. and Ext. switch use

Internal Reed Switch

External Reed Switch

Int + Ext Reed Switch

External

Input

Terminals

To

Initiating

Device

Mounting

Holes

Base

Wedge

I N S T A L L A T I O N I N S T R U C T I O N SDoor Contact Models CT600/CT610/CT201/CT211/CT700/CT710