Structure and Operation

4

Digital timer of operating unit

A digital timer with day and week

feature, calendar, automatic resetting to

daylight savings time and automatic

functions for domestic hot water heating

and recirculation pump.

Time, day and standard switching times

for space heating, domestic hot water

heating and the domestic hot water

recirculation pump are factory preset

(individually programmable) max. four

time switch intervals programmable per

day

Shortest interval: 1 minutes

Power reserve: 5 years

Adjusting the operating mode

All operating modes provide freeze-up

protection*1 for the heating system.

With the program selector buttons the

following can be selected:

-- heating and domestic hot water

-- domestic hot water only

-- standby operation

*1 see “Freeze-up protection function”

below.

Freeze-up protection function

The freeze-up protection function is

-- activated when the outdoor

temperature drops to +34 ºF/ 1ºC.

Freeze-up protection activates the

circulation pumps and keeps the boiler

water temperature at the reduced

operation setpoint level, at a minimum

temperature of approx. 68 ºF / 2 ºC

(for heating boilers with low limit the

respective temperature will be

maintained).

-- deactivated when the outdoor

temperature exceeds 37 ºF / 3 ºC.

When the freeze-up protection function

is deactivated, heating boiler and

circulation pumps are turned off.

Summer economy mode

(Domestic hot water heating only,

program selector switch ” ”)

The burner only activates if domestic hot

water needs to be produced (as required

by DHW setpoint).

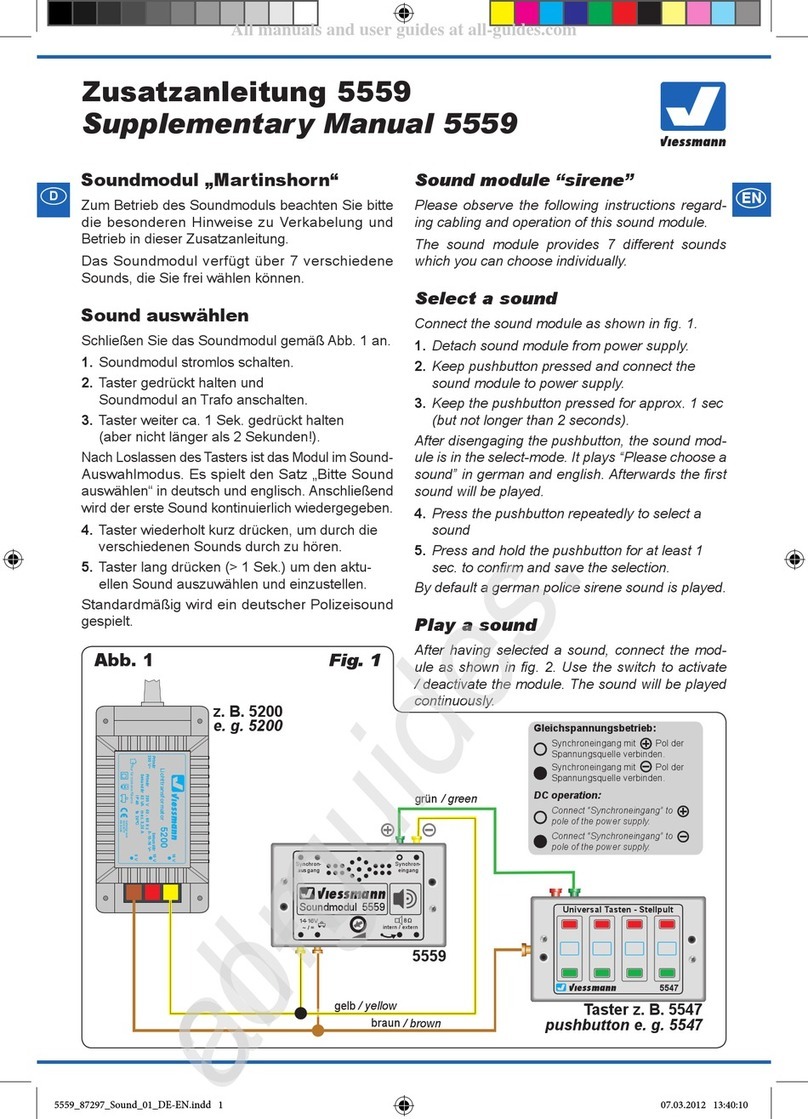

Heating curve adjustment

The weather-responsive Vitotronic 3

regulates the boiler water temperature

(= supply temperature of the heating

circuit without a mixing valve) and the

supply temperature of the heating circuit

with mixing valves.

Boiler water temperature is maintained

from to 72 ºF / to 4 ºC above the

calculated supply temperature of either

mixing valve circuit (factory default

setting 5 ºF / 8 ºC).

The required boiler supply temperature

for a certain room temperature depends

on the heating system and the insulation

of the building in question. The

adjustment of each heating curve allows

for the boiler water temperature and the

supply water temperature of the mixing

valve circuits to adjust to these

conditions.

Heating curves:

Low temperature heating system,

e.g. radiant floor heating

Medium temperature heating system,

e.g. cast iron radiation, staple-up

radiant floor heating

High temperature heating system,

e.g. fintube radiation, fan coils

The maximum boiler water temperature is

restricted by both the adjustable high

limit and the electronic maximum

temperature limit.

The supply water temperature cannot

exceed the boiler water temperature.

Boiler water temperature sensor

Cable length 5.2 ft./1.6 m,

ready to plug in.

Maximum ambient temperature

– at operation: 32 to 266 ºF

to 13 ºC

– when storing or transporting:

–4 to +158 ºF

–2 to +7 ºC

Outdoor temperature sensor

Installation site:

-- North or northwest side of building

-- 6.6 to 8.2 ft. / 2 to 2.5 m above

ground, for multi-storey buildings mount

sensor on upper half of second floor.

Connection:

-- 2-wire cable, cable length 115 ft. /

35 m with a wire size of min. AWG 16

copper.

-- the cable to the outdoor sensor must

not be laid near line voltage wiring

(12 / 24 V).

Maximum ambient temperature at

operation,

when storing or

transporting: – 4 to +158 ºF

– 4 to +7 ºC

Domestic hot water tank temperature

sensor

Cable length 19 ft. / 5.8 m,

ready to plug in.

Maximum ambient

temperature:

– at operation: 32 to 194 ºF

to 9 ºC

– when storing or transporting:

–4 to +158 ºF

–2 to +7 ºC

5265 533 v1.4