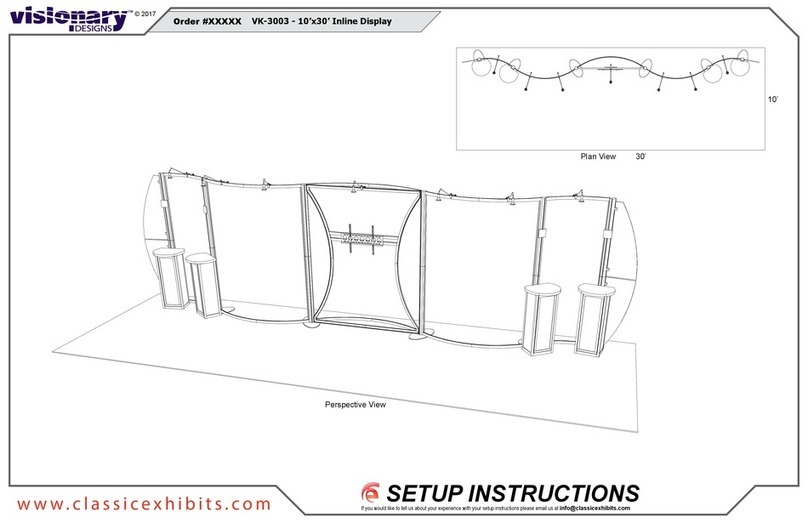

VISIONARY DESIGNS VK-1227 User manual

Other VISIONARY DESIGNS Indoor Furnishing manuals

VISIONARY DESIGNS

VISIONARY DESIGNS LTK-1001 User manual

VISIONARY DESIGNS

VISIONARY DESIGNS VK-2922 Manual

VISIONARY DESIGNS

VISIONARY DESIGNS VK-1032 Manual

VISIONARY DESIGNS

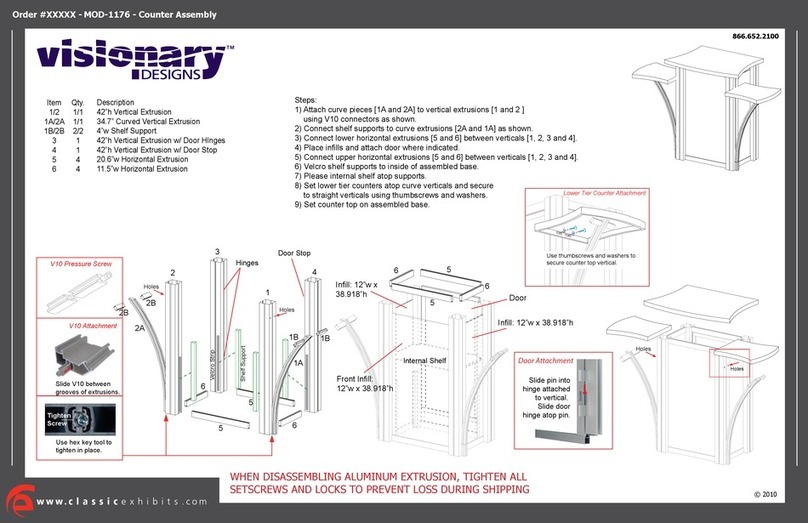

VISIONARY DESIGNS MOD-1176 User manual

VISIONARY DESIGNS

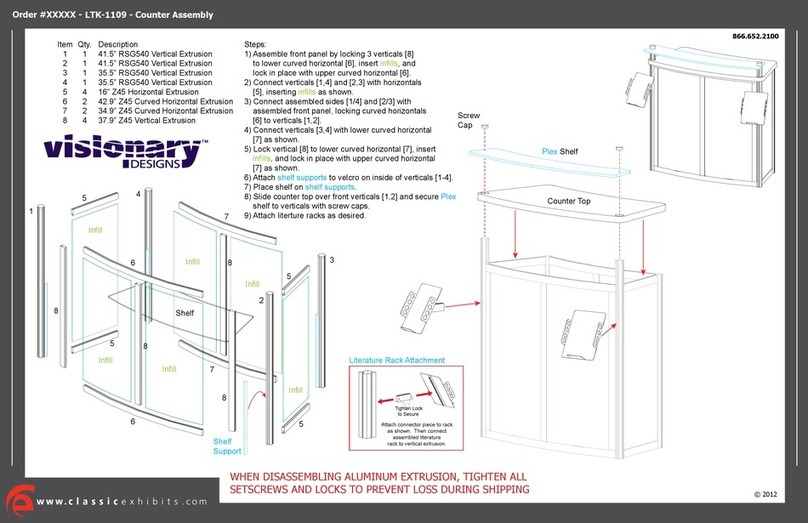

VISIONARY DESIGNS LTK-1109 User manual

VISIONARY DESIGNS

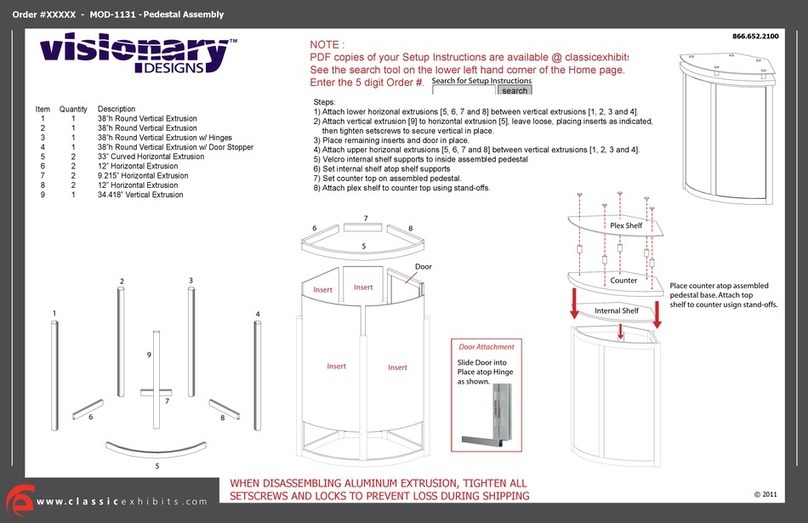

VISIONARY DESIGNS MOD-1131 User manual

VISIONARY DESIGNS

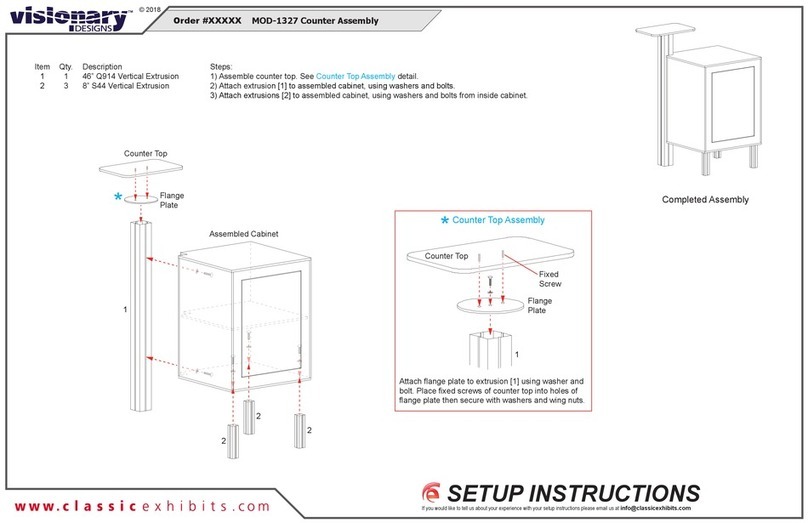

VISIONARY DESIGNS MOD-1327 User manual

VISIONARY DESIGNS

VISIONARY DESIGNS RE-2070 Manual

VISIONARY DESIGNS

VISIONARY DESIGNS MOD-1454 Manual

VISIONARY DESIGNS

VISIONARY DESIGNS MOD-1701c Manual

VISIONARY DESIGNS

VISIONARY DESIGNS VK-1048 Manual

VISIONARY DESIGNS

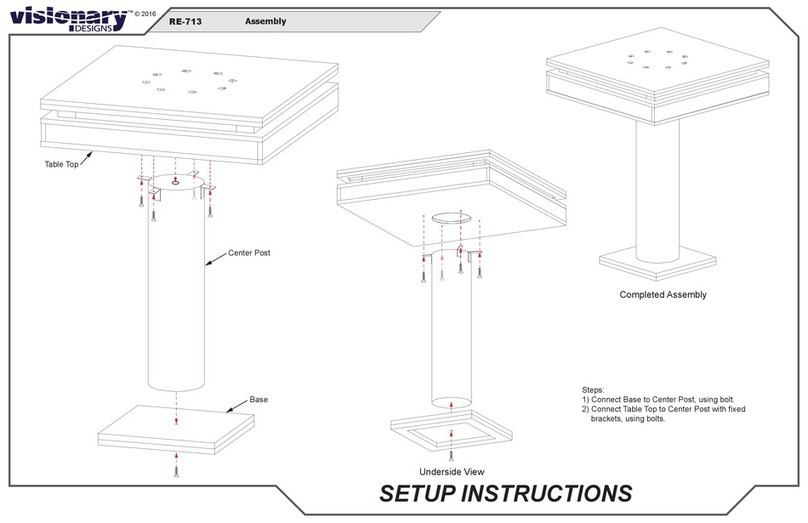

VISIONARY DESIGNS RE-713 Manual

VISIONARY DESIGNS

VISIONARY DESIGNS VK-1334 Manual

VISIONARY DESIGNS

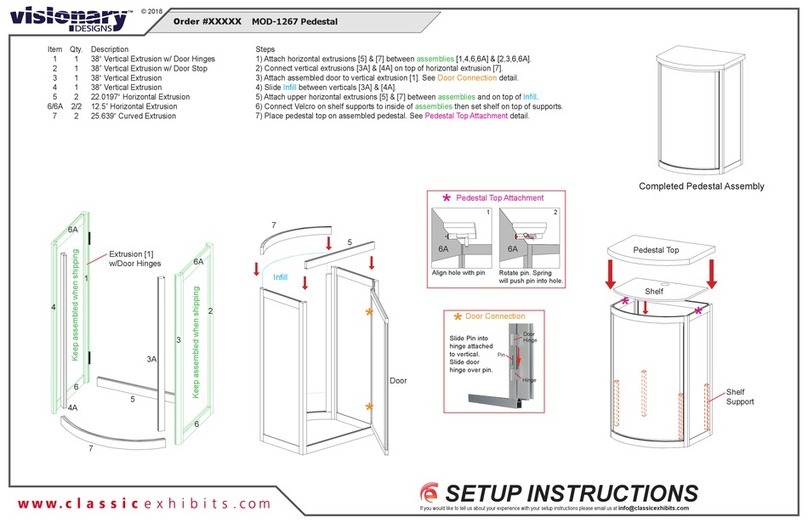

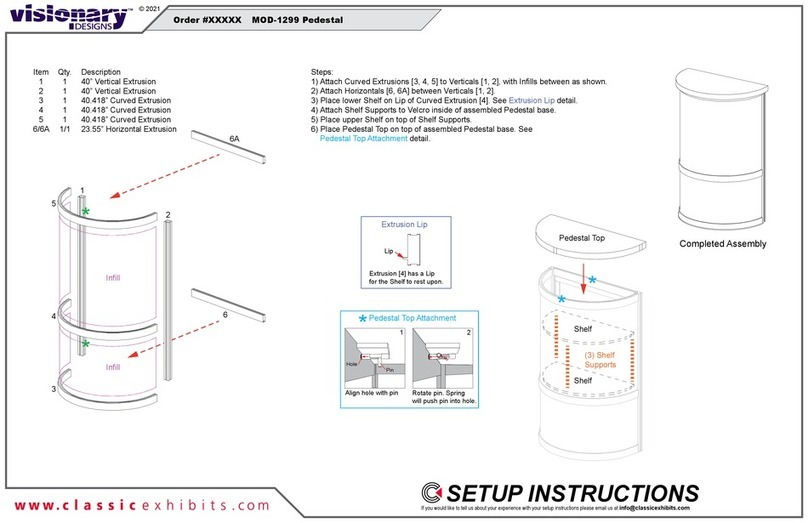

VISIONARY DESIGNS MOD-1299 Manual

VISIONARY DESIGNS

VISIONARY DESIGNS MOD-1243 Manual

VISIONARY DESIGNS

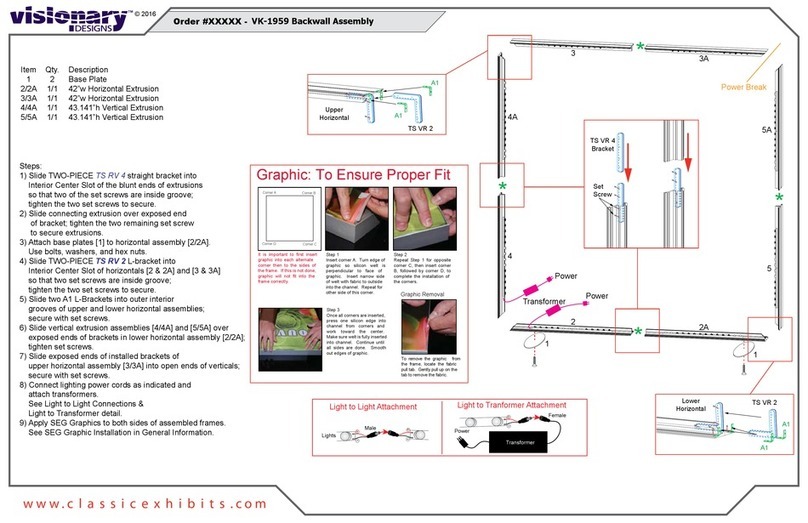

VISIONARY DESIGNS VK-1959 User manual

VISIONARY DESIGNS

VISIONARY DESIGNS VK-2921 Manual

VISIONARY DESIGNS

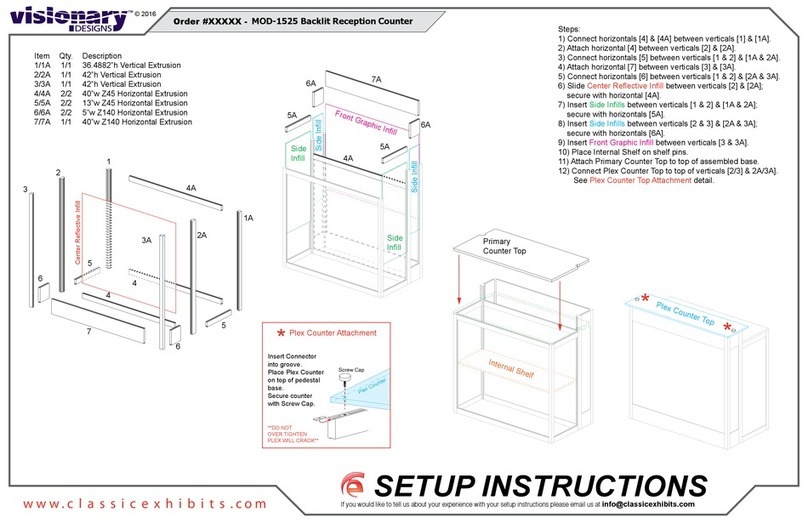

VISIONARY DESIGNS MOD-1525 Manual

VISIONARY DESIGNS

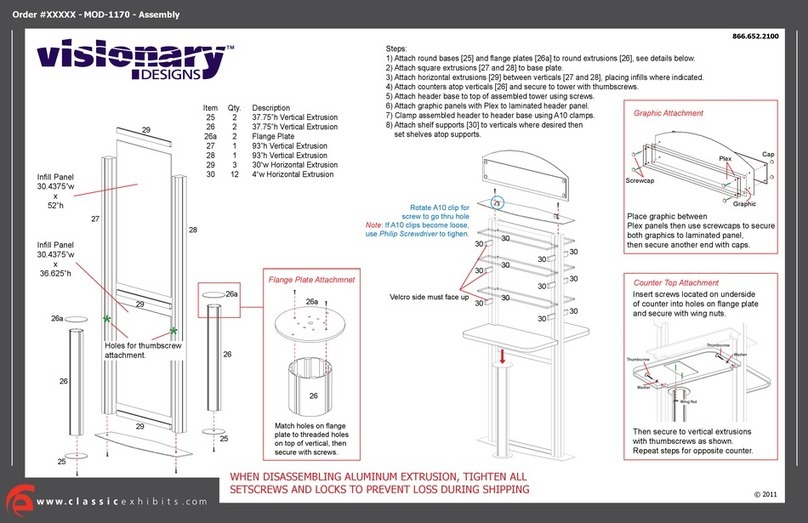

VISIONARY DESIGNS MOD-1170 User manual

VISIONARY DESIGNS

VISIONARY DESIGNS Hybrid Inline VK-1100 Manual

Popular Indoor Furnishing manuals by other brands

Sauder

Sauder Beginnings 424257 Instruction booklet

WWBeds

WWBeds Alpha Murphy Assembly instructions

Emerson

Emerson Closetmaid 1043 Assembly manual

Forte

Forte KZMR621LB Assembling Instruction

Universal Furniture

Universal Furniture 572230 instruction sheet

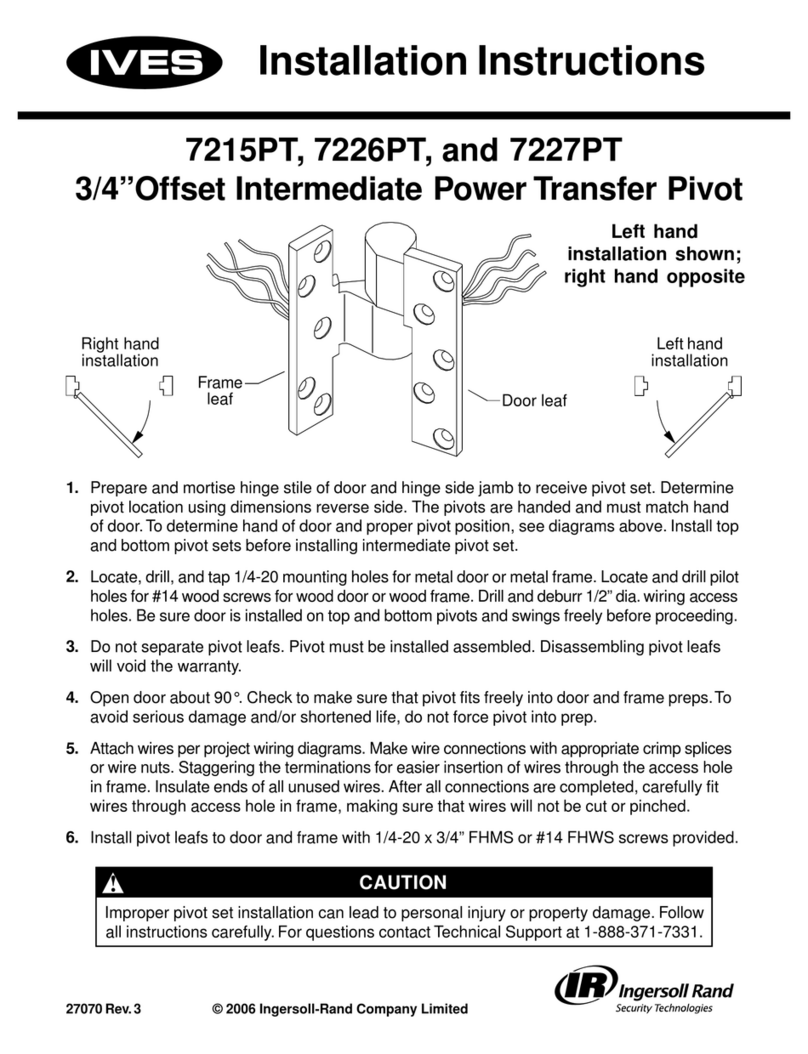

Ives

Ives Offset Intermediate Power Transfer Pivot... installation instructions

Regalo

Regalo Home Accents Widespan 1176 B instructions

Lakeland

Lakeland 23357 user manual

Ameriwood HOME

Ameriwood HOME 8782220W Instruction booklet

Costway

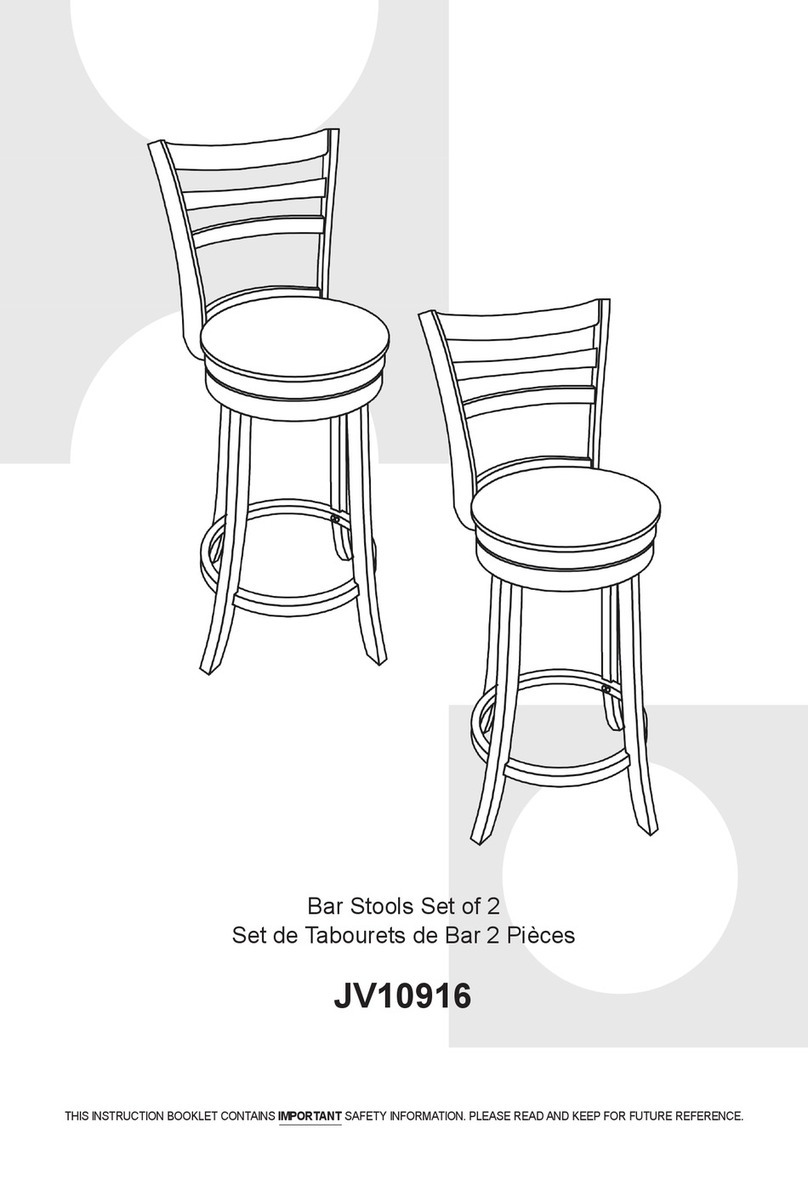

Costway NP10174WH manual

Balmani

Balmani Mitra Elements column cabinet - lacquer installation guide

New Classic Furniture

New Classic Furniture ANTON UC2177-30P1-PBK Assembly instructions