•

•

•

•

CABLE

CONNECTION

STEP NO. 3 - Remove panel underneath

steering wheel

to

expose under

das

h area.

STEP NO. 4 - Disconnect speedometer cable

from

speedometer and transmission. Remove

cable clamps and firewall grommet. Remove

cable

from

vehicle.

NOTE:

Oil

seal

at transmission cable connec·

tion.

This

seal

must

be

in place when

new

cable

is

installed.

STEP NO. 5 - Insert new speedometer cable (3)

through

firewall and connect plastic

nut

end

to

speedometer. Route free end

of

cable

toward

regulator

area

and install

grommet

suppli

ed

on

new cable i

nto

firewall hole.

STEP NO. 6 - Route transmission cable (4)

from

engine

compartmen

t

to

transmission and con·

nec!. Reattach

al

l existing cable clamps

so

that

new cable follows original cable

routing.

STEP NO. 7 -

Approx.

12 inches

forward

of

the existing transmission cable clamp,

drill

a

5/

32"

hole and

mount

new transmission cable

clamp (11)

with

sheet metal screw (10)

pro

·

vided.

NOTE:

The purpose

of

this

new

clamp

is

to

keep the transmission cable away

from

the

exhaust

manifoid.

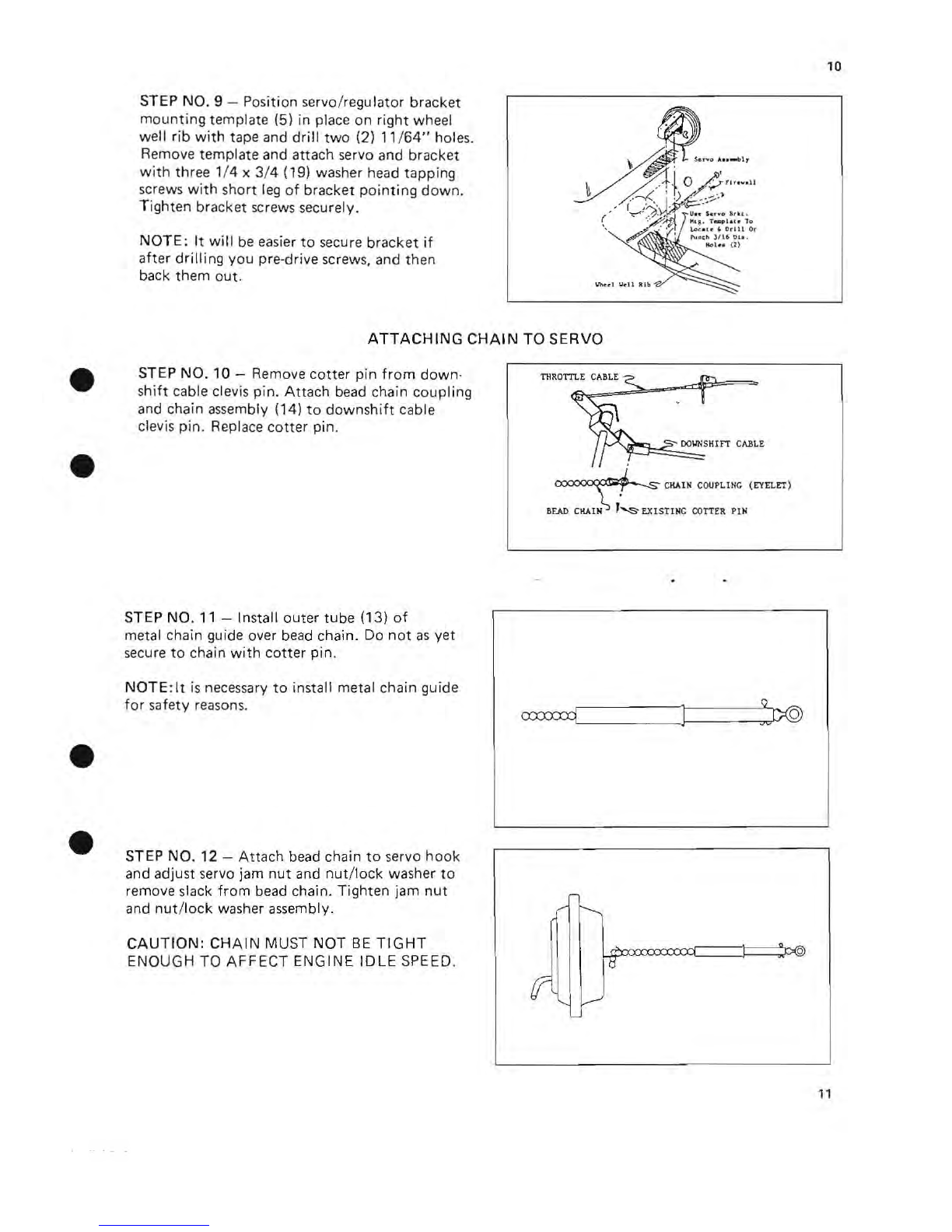

SERVO

MOUNTING

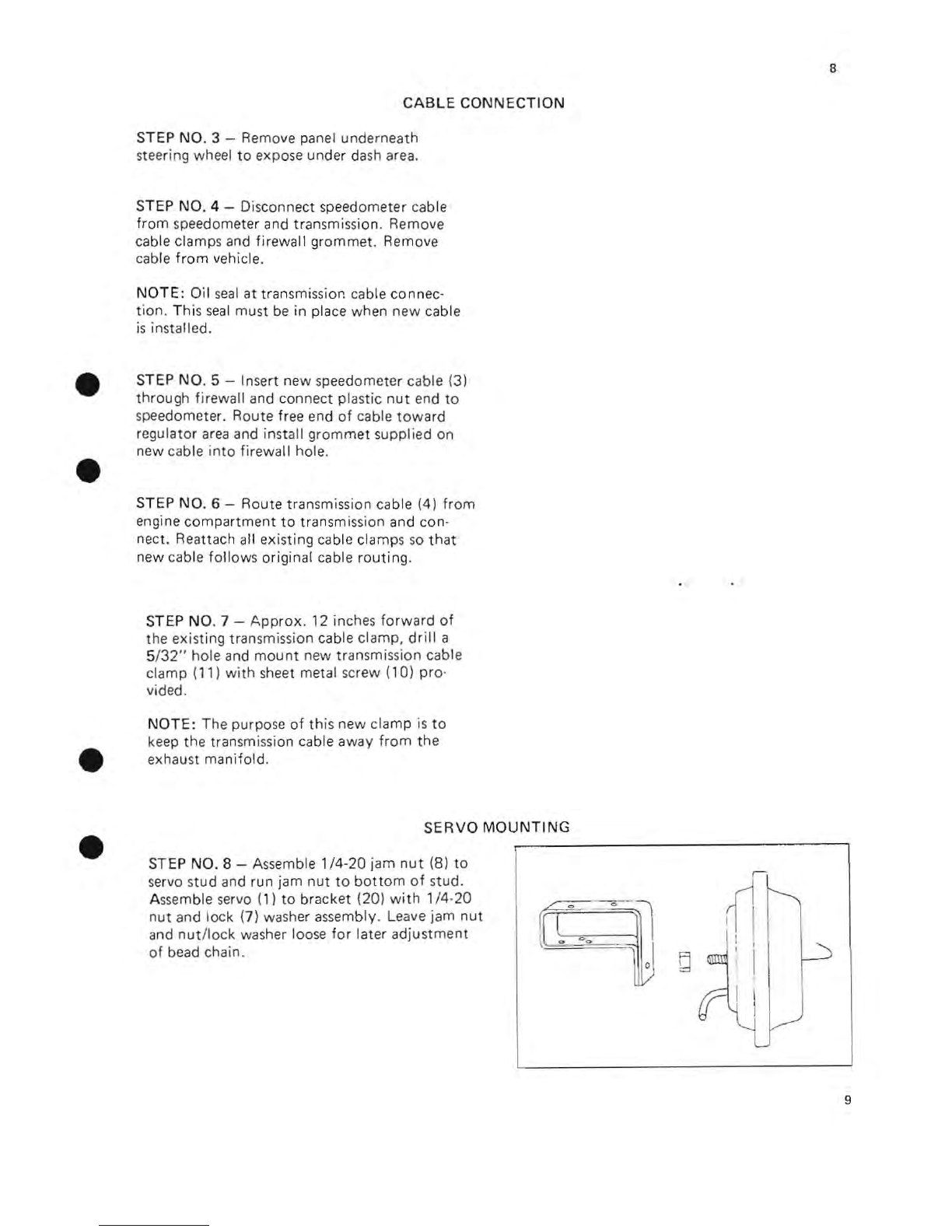

STEP NO. 8 - Assemble

1/4·20

jam

nut

(8)

to

servo s

tud

and run jam

nut

to

bottom

of

stud.

Assemble servo (1)

to

bracket (20)

with

1/4·

20

nut

and lock (7) washer assembly. Leave jam

nut

and

nut

/lock washer loose

for

later

adjustment

of

bead chain.

8

9