11

Before use

WARNING

High voltage danger from power source! Consult a qualified electrician for proper installation

of needed socket. This welder must be grounded while in use to protect the operator from electric shock.

If you are not sure that your outlet is properly grounded, have it checked by a qualified electrician. Do

not remove grounding prong or alter the plug in any way. Do not use any adapters between the

welder’s power cord and the power source socket. Make sure the POWER switch is in OFF position

when connecting your welder’s power cord to a properly grounded 220/230VAC, 50/60Hz,

20 amp, single phase mains supply.

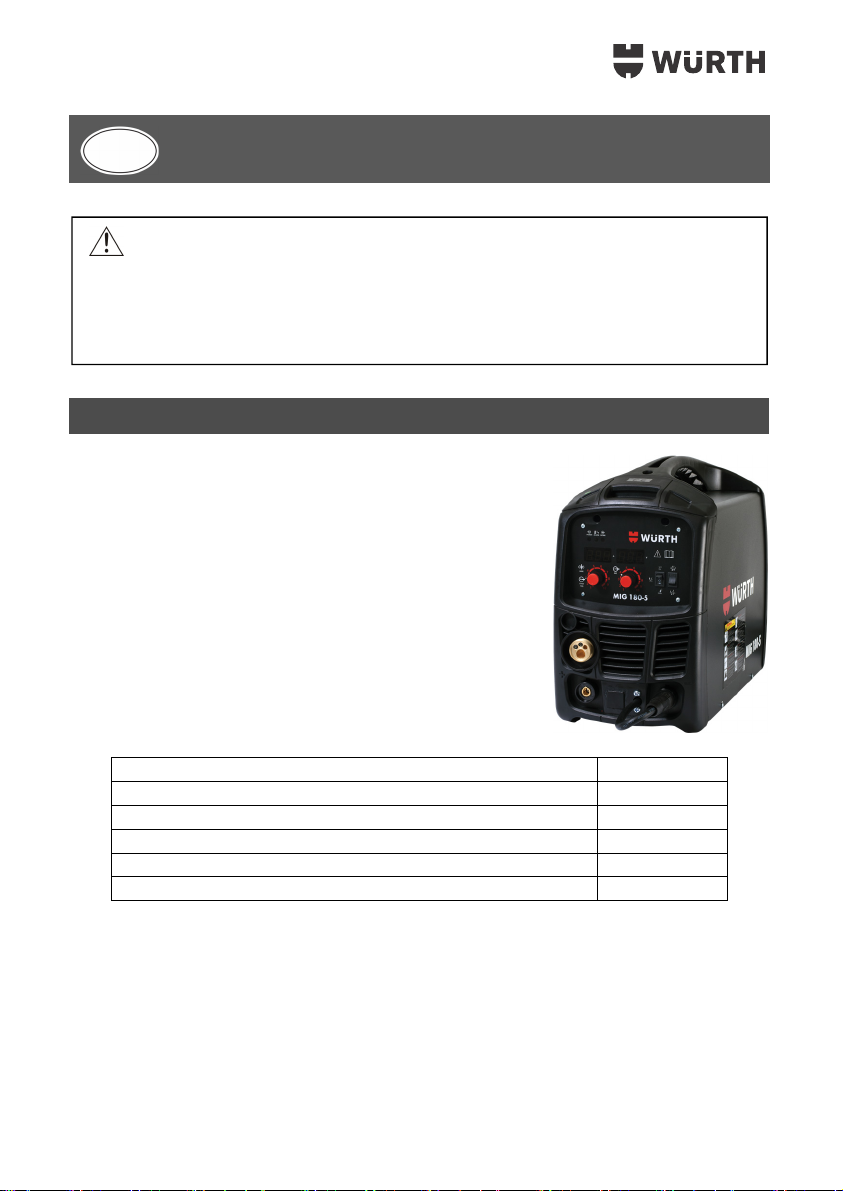

THE MIG WELDING OPERATION

1. Main controls

Power switch – The power switch supplies electrical current to the welder. Whenever the power

switch is in the ON position, the welding circuit is activated. ALWAYS turn the power switch to the OFF

position and unplug the welder before performing any maintenance.

Voltage selector – The voltage selector controls the welding heat. This unit has infinite voltage

control. Refer to the label inside the welder side door for recommended voltage selector settings

required for your welding job.

Wire speed control – The wire speed control adjusts the speed at which the wire is fed out of the

welding torch. The wire speed needs to be closely matched (tuned-in) to the rate at which it is being

melted off. Some of the few things that affect wire speed selection are the type and wire diameter being

used, the heat setting selected, and the welding position to be used.

Note: The wire will feed faster without welding arc established. When an arc is being drawn, the wire

speed will slow down.

2. Holding the torch

The best way to hold the welding torch is the way that feels most comfortable to you. While practicing

to use your new welder, experiment holding the torch in different positions until you find the one that

seems to work best for you.

3. Positioning the torch onto the workpiece

There are two angles of the torch nozzle in relation to the workpiece that must be considered when

welding.

3.1. Angle A can be varied, but in most cases the optimum angle will be 60 degrees, the point at

which the torch handle is parallel to the work piece. If angle A is increased, penetration will

increase. As angle A is decreased, the penetration is decreased as well.