3

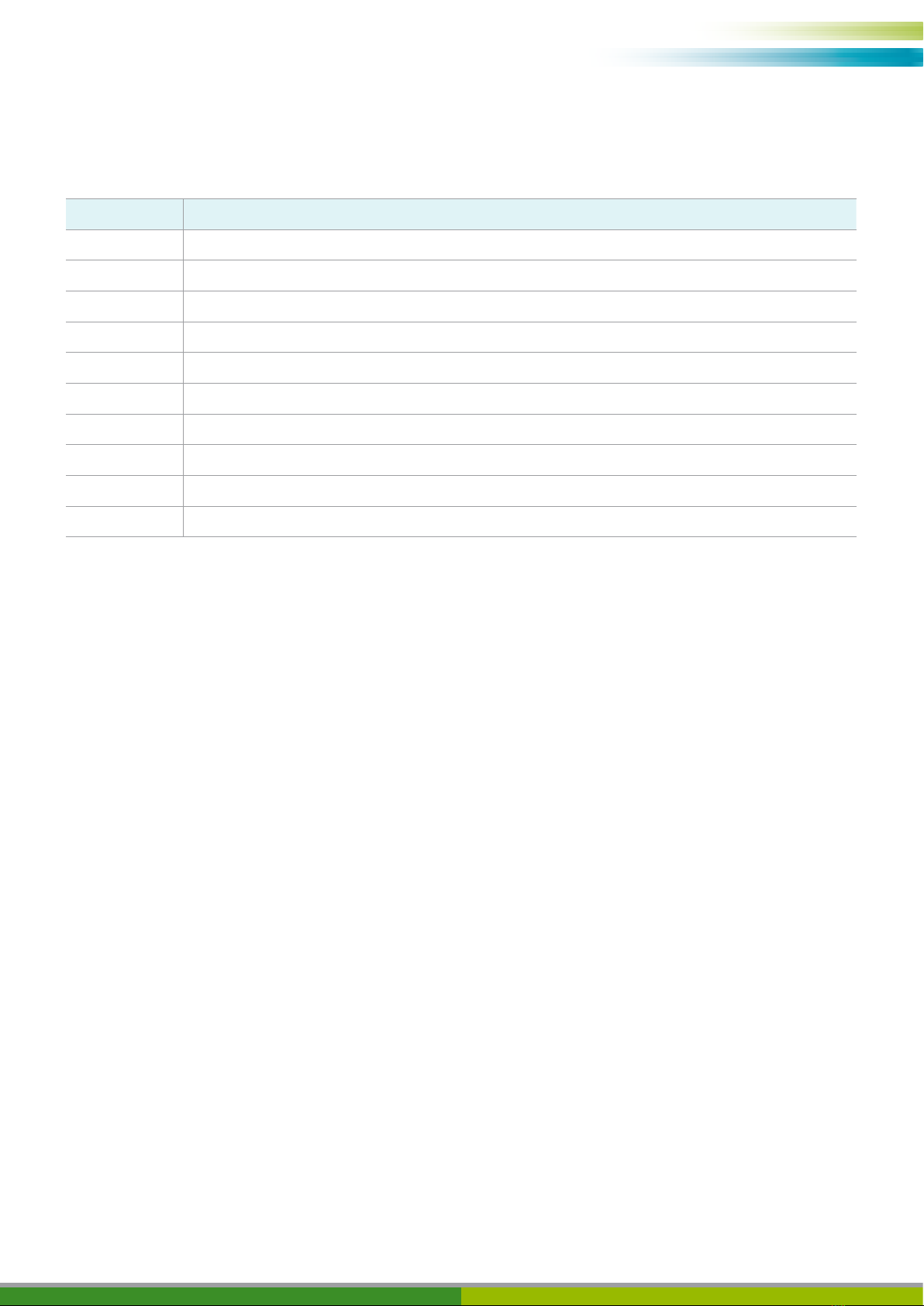

Table of contents

Table of contents

1 List of abbreviations ........................................................................................................................................ 5

2 Information about this document ................................................................................................................... 6

2.1 General equal treatment ......................................................................................................................... 6

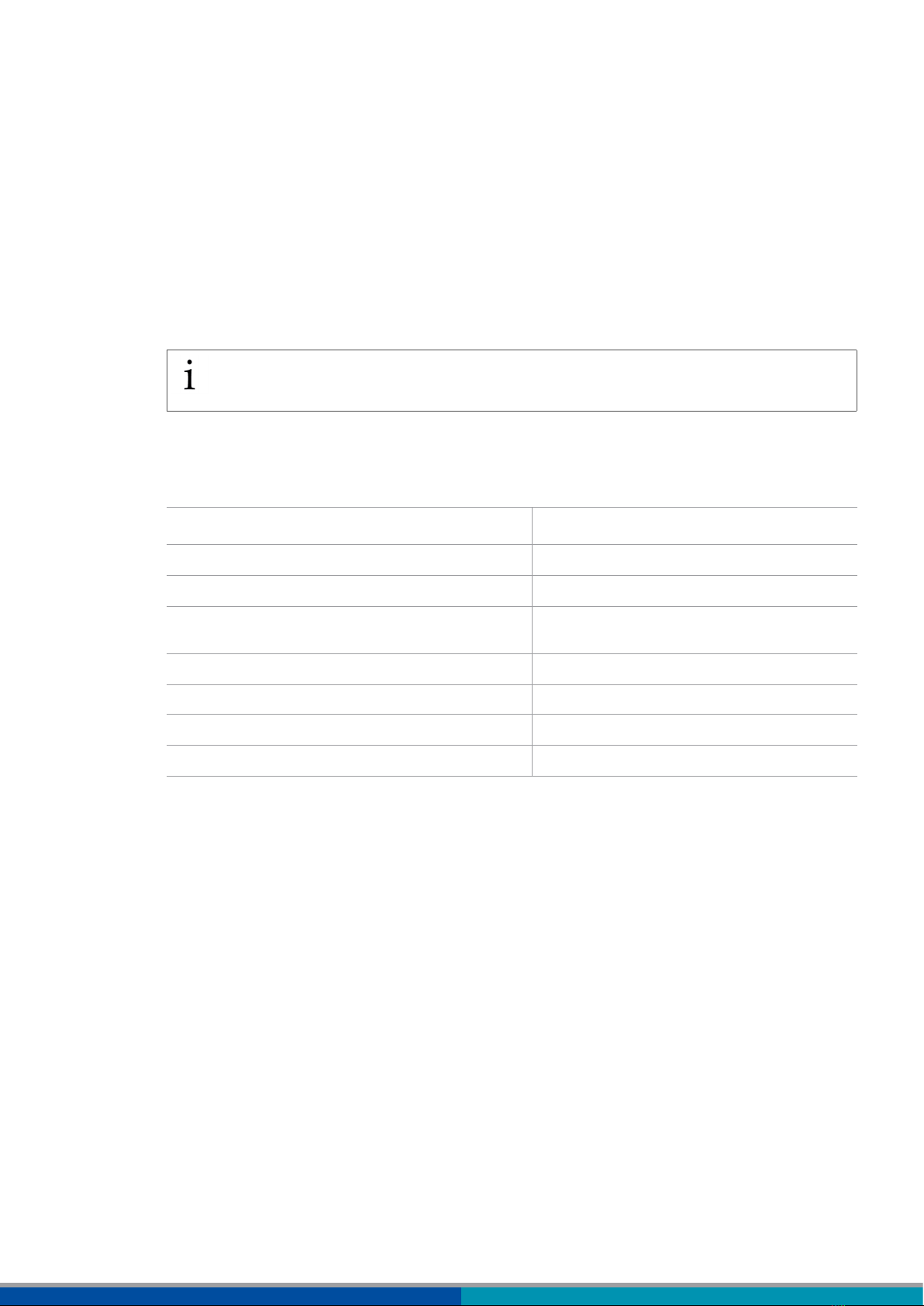

2.2 Symbols used ......................................................................................................................................... 6

3 Basic safety instructions................................................................................................................................. 7

3.1 Proper use .............................................................................................................................................. 7

3.2 Obvious misuse ...................................................................................................................................... 7

3.3 Qualication and knowledge of the personnel ........................................................................................ 7

3.4 Structure and explanation of the warning notes...................................................................................... 7

3.4.1 Structure of the warning notes .................................................................................................. 7

3.4.2 Explanation of the warning notes .............................................................................................. 8

3.5 General safety instructions ..................................................................................................................... 8

3.6 Personal protective equipment ............................................................................................................... 8

4 Introduction ...................................................................................................................................................... 9

5 Technical description .................................................................................................................................... 10

5.1 Scope of supply .................................................................................................................................... 10

5.2 Technical data ....................................................................................................................................... 10

5.3 Overview graphics ................................................................................................................................ 11

5.3.1 Structure.................................................................................................................................. 11

5.3.2 Connections and operating elements on the training model ................................................... 12

5.3.3 Indicator lights ......................................................................................................................... 13

5.4 Installed systems/components.............................................................................................................. 13

5.5 ECAS remote control unit ..................................................................................................................... 14

6 Setting up........................................................................................................................................................ 15

7 Start-up ........................................................................................................................................................... 16

7.1 Establishing the compressed air supply................................................................................................ 16

7.2 Establishing the power supply .............................................................................................................. 16

7.3 Switching on the ignition ....................................................................................................................... 17

7.4 Initial start-up of EBS 3 ......................................................................................................................... 18

8 Function and operation ................................................................................................................................. 19

8.1 Brake function ....................................................................................................................................... 19

8.2 Air suspension (ECAS) ......................................................................................................................... 20

8.3 Operation with switches in the driver's cab........................................................................................... 20

8.3.1 Lighting.................................................................................................................................... 20

8.3.2 Reverse monitoring system..................................................................................................... 20

8.3.3 Lifting and lowering the lifting axle .......................................................................................... 20

8.3.4 Activating and deactivating the traction help........................................................................... 21

8.3.5 Regulation of the driving level ................................................................................................. 21

8.4 Operation with the ECAS remote control unit ....................................................................................... 21