2

Table of Contents

Table of Contents

1 General Information ......................................................................................................................................... 4

2 Safety Information............................................................................................................................................ 6

2.1 Trailer Grounding and Protection from Electrostatic Discharge ..............................................................7

2.2 Vehicle Electrical Grounding Guidelines ................................................................................................. 7

3 Introduction ...................................................................................................................................................... 9

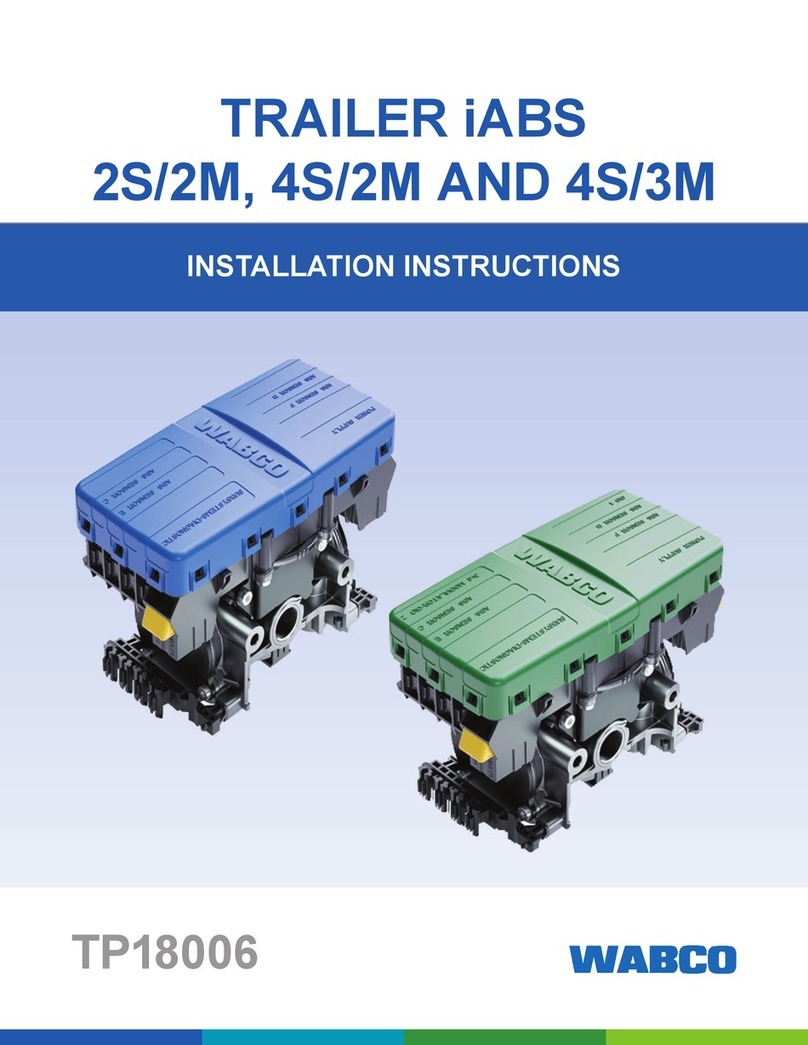

3.1 Identifying iABS....................................................................................................................................... 9

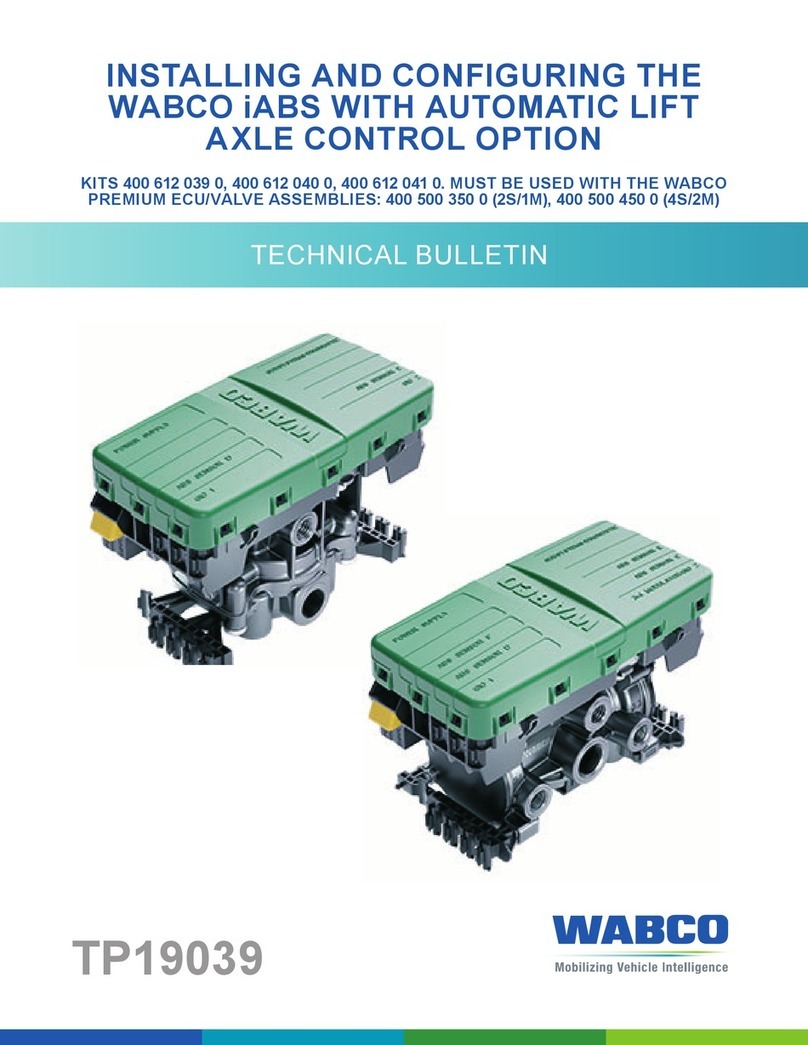

3.2 iABS Trailer ABS Parts.......................................................................................................................... 10

3.3 What Is WABCO’s iABS Trailer ABS?................................................................................................... 10

3.4 System Configuration............................................................................................................................ 10

3.5 How Trailer ABS Works......................................................................................................................... 11

3.6 System Components............................................................................................................................. 11

4 ABS Questions and Answers........................................................................................................................ 15

4.1 The ECU ............................................................................................................................................... 15

4.2 Power Line Carrier (PLC)...................................................................................................................... 15

4.3 ABS Indicator Lamps ............................................................................................................................ 16

4.4 Types of Faults...................................................................................................................................... 18

4.5 Frequently Asked Questions ................................................................................................................. 19

5 System Configurations.................................................................................................................................. 20

5.1 iABS Installation Diagrams ................................................................................................................... 20

5.2 Power Cable Wiring Diagrams.............................................................................................................. 29

6 Diagnostics..................................................................................................................................................... 30

6.1 Important PLC Information for Blink Code Diagnostics......................................................................... 30

6.2 TOOLBOX PLUS™ SOFTWARE ......................................................................................................... 31

6.3 Initial Power-up Check .......................................................................................................................... 37

6.4 Power and Ground Checks .................................................................................................................. 37

6.5 Blink Code Diagnostics ......................................................................................................................... 38

7 Component Replacement............................................................................................................................ 115

7.1 Wheel Speed Sensor .......................................................................................................................... 116

7.2 ABS Relay Valve (Figure 7.3) ............................................................................................................. 117

7.3 ECU/Valve Assembly .......................................................................................................................... 118