7

Preparation

4 Preparation

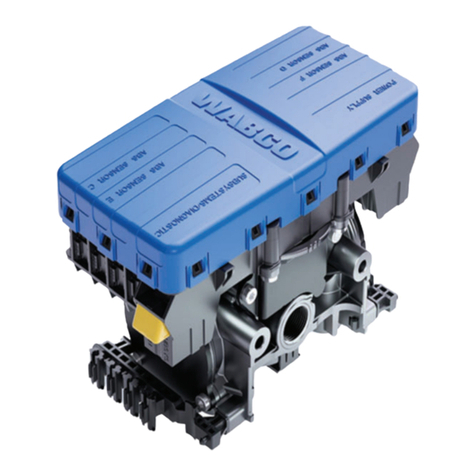

1. Before beginning the installation procedure, inspect the ECU/dual modulator valve assembly for

damage that may have occurred during shipping or storage.

Look for damaged or broken connectors.

Do not install a damaged ECU/dual modulator valve assembly. Notify your supervisor, or contact

WABCO if there is any apparent damage.

2. Have the following installation material available.

WABCO Components:

ECU/dual modulator valve assembly

ABS relay valve and relay valve extension cable (3M system only)

Power cable or power/diagnostic cable

Sensor extension cables (two pieces for 2S systems, four pieces for 4S systems)

ABS sensors (two or four) for non-ABS prepped axles

ABS Indicator Label (TP-95172)

Non-WABCO Components:

5/8-inch O.D. nylon tubing for supply (frame mount)

Pipe plug (3/4-inch NPT)

Schedule 80 hex pipe nipple (3/4-inch NPT) for air tank mounts or two Grade 8 bolts (3/8-inch)

and prevailing torque nuts for frame mounts

ABS sensor clip lubricant (the following are approved by WABCO):

•Mobilith SHC-220 (Mobil)

•TEK 662 (Roy Dean Products)

•Staburags NBU 30 PTM (Kluber Lubrication)

•Valvoline EP 633

SAE-standard, DOT-approved sealing paste

ABS indication lamp (to ensure correct lamp operation, use an incandescent-type DOT-approved

lamp, or an LED with integral load resistor)

All WABCO component part number information can be found in Appendix IV.

End of line testing must be done after all installations. WABCO recommends using TOOLBOX PLUS™

Software to perform this testing. If you do not have TOOLBOX PLUS™ Software, this bulletin also includes

instructions for testing without the software. The TOOLBOX PLUS™ Software can be purchased and

downloaded from www.wabco-snapon.com.