29

CONTENTS

Contents

1 SAFETY REGULATIONS FOR AIRLESS SPRAYING 30

1.1 Flash point_________________________________ 30

1.2 Explosion protection_________________________ 30

1.3 Danger of explosion and re from sources of

ignition during spraying work _________________ 30

1.4 Danger of injury from the spray jet _____________ 30

1.5 Secure spray gun against unintended operation __ 30

1.6 Recoil of spray gun __________________________ 30

1.7 Breathing equipment as protection against

solvent vapors______________________________ 30

1.8 Prevention of occupational illnesses ____________ 30

1.9 Max. operating pressure______________________ 31

1.10 High-pressure hose _________________________ 31

1.11 Electrostatic charging

(formation of sparks or ames) ________________ 31

1.12 Use of units on building sites and workshops_____ 31

1.13 Ventilation when spraying in rooms ____________ 31

1.14 Suction installations _________________________ 31

1.15 Earthing of the object________________________ 31

1.16 Cleaning the unit with solvents ________________ 31

1.17 Cleaning the unit ___________________________ 31

1.18 Work or repairs at the electrical equipment ______ 31

1.19 Work at electrical components_________________ 32

1.20 Setup on an uneven surface___________________ 32

2 GENERAL VIEW OF APPLICATION ____________ 32

2.1 Application ________________________________ 32

2.2 Coating material ____________________________ 32

2.2.1 Coating materials with sharp-edged additional

materials __________________________________ 32

2.2.2 Filtering (for spay work) ______________________ 32

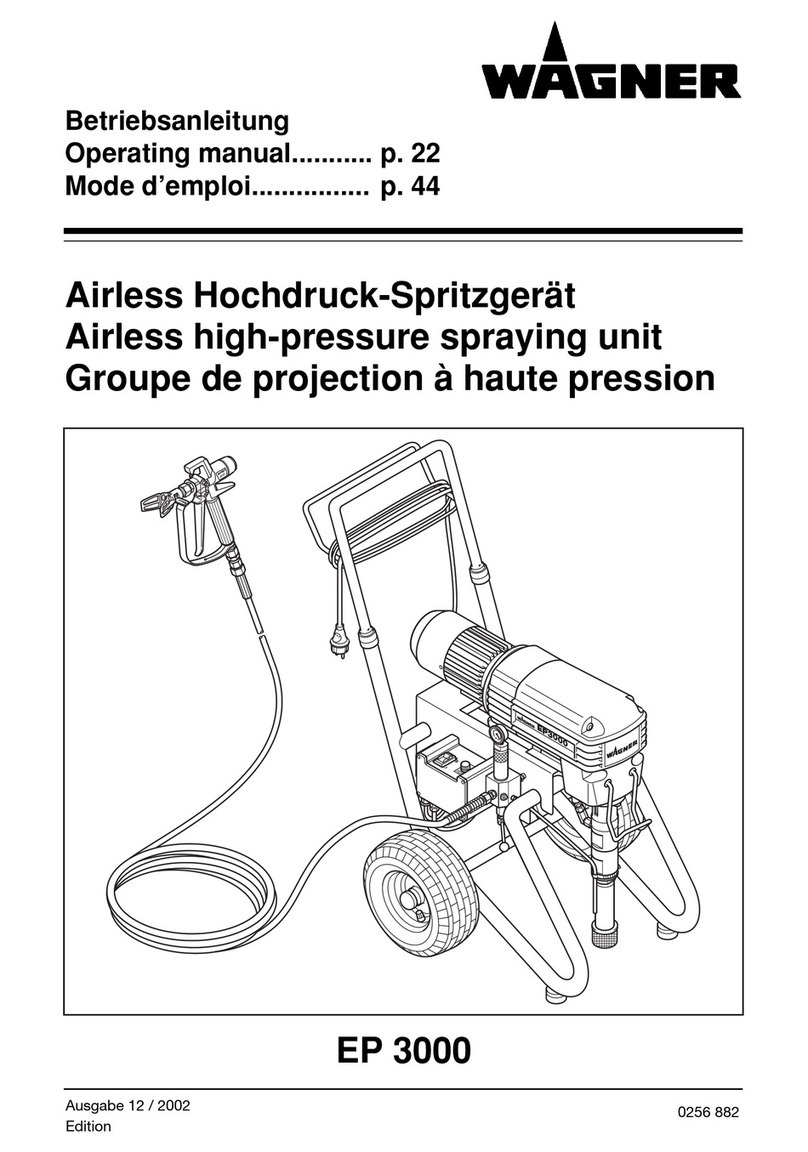

3. DESCRIPTION OF UNIT _____________________ 33

3.1 Functioning of the unit_______________________ 33

3.2 Two-position operation ______________________ 33

3.3 Explanatory diagram_________________________ 34

3.4 Technical data ______________________________ 35

4 STARTUP _________________________________ 35

4.1 Gun ______________________________________ 35

4.2 High pressure hose and pressure gauge _________ 36

4.3 Hopper____________________________________ 36

4.4 Suction system _____________________________ 36

4.5 Connection to the mains network ______________ 37

4.6 Cleaning preserving agent when starting-up of

operation initially ___________________________ 37

4.6 Ventilate unit (hydraulic system) if the sound of

inlet valve is not audible______________________ 36

4.7 Taking the unit into operation with

coating material ____________________________ 36

5 TRANSPORTATION _________________________ 38

6 HANDLING THE HIGHPRESSURE HOSE_______ 38

7 INTERRUPTION OF WORK ___________________ 38

8 CLEANING THE UNIT _______________________ 39

8.1 Cleaning the unit from the outside _____________ 39

8.2 Suction lter _______________________________ 39

8.3 Cleaning the Airless spray gun_________________ 40

9 SERVICING ________________________________ 40

9.1 General servicing ___________________________ 40

9.2 High-pressure hose__________________________ 40

10 REPAIRS AT THE UNIT ______________________ 41

10.1 Inlet valve Pusher ___________________________ 41

10.2 Inlet valve _________________________________ 41

10.3 Outlet valve ________________________________ 42

10.4 Pressure control valve________________________ 42

10.5 Typical wear parts ___________________________ 42

10.6 Remedy in case of faults ______________________ 45

11 SPARE PARTS AND ACCESSORIES ____________ 44

11.1 Super Finish 23 CR accessories_________________ 44

11.2 Spare parts list Super Finish 23 CR _____________ 49

11.3 Spare parts List Trolley _______________________ 50

11.4 Spare parts list hopper 5l _____________________ 50

Testing of the unit ________________________________ 51

Important information on product liability_____________ 51

Note on disposal__________________________________ 51

Guarantee declaration _____________________________ 51

CE - declaration___________________________________ 52

European service network _________________________ 132