- 1 -

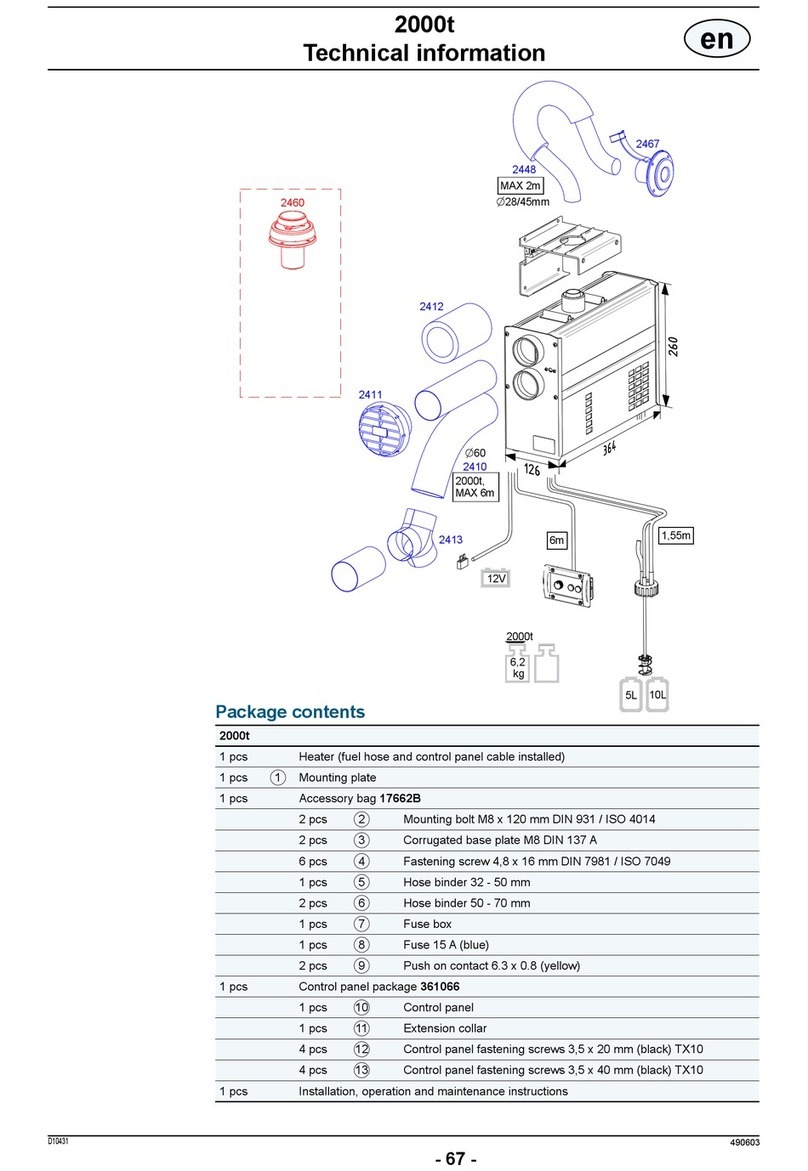

Technical information - Accessories and measures 2 ....................................................................................

2 .....................................................................................................................................................................................

Technical information - Technical information 3 ............................................................................................

3 .....................................................................................................................................................................................

Technical information - Operation description 4 ............................................................................................

4 .....................................................................................................................................................................................

Technical information - Things to note before Installation 5 .......................................................................

5 .....................................................................................................................................................................................

Installation - Fastening the device 6 ................................................................................................................

6 .....................................................................................................................................................................................

Installation - Electrical connections 9 ..............................................................................................................

9 .....................................................................................................................................................................................

Installation - Electrical connections B 9 ..........................................................................................................

9 .....................................................................................................................................................................................

Installation - Warm air ducting 12 ....................................................................................................................

12 ...................................................................................................................................................................................

Exhaust gas connections - Exhaust gas connections coaxial 13 ..................................................................

13 ...................................................................................................................................................................................

Exhaust gas connections - Side lead-through 2467 15 .................................................................................

15 ...................................................................................................................................................................................

Exhaust gas connections - Closable lead-through 2460 16 ..........................................................................

16 ...................................................................................................................................................................................

Exhaust gas connections - Stern lead-through 5400 17 ...............................................................................

17 ...................................................................................................................................................................................

Exhaust gas connections - Insulation kit 17 ....................................................................................................

17 ...................................................................................................................................................................................

Fuel connections - Fuel connections 18 ...........................................................................................................

18 ...................................................................................................................................................................................

Fuel connections - Fixed tank connection 30011 19 ......................................................................................

19 ...................................................................................................................................................................................

Fuel connections - Separate tank connection 20 ...........................................................................................

20 ...................................................................................................................................................................................

Fuel connections - Solenoid valve 21 ...............................................................................................................

21 ...................................................................................................................................................................................

Fuel connections - Tank external filters 22 .....................................................................................................

22 ...................................................................................................................................................................................

Operation - Device operation 23 .......................................................................................................................

23 ...................................................................................................................................................................................

Control Panel functions for 3007 and 3008 - Control Panel basic features. 25 ........................................

25 ...................................................................................................................................................................................

Control Panel - Software update 29 .................................................................................................................

29 ...................................................................................................................................................................................

Control Panel - Wallas Remote application and Control Panel connection 30 ..........................................

30 ...................................................................................................................................................................................

Installation and initial start-up - Installation and initial start-up 34 ..........................................................

34 ...................................................................................................................................................................................

Maintenance - Maintenance recommendations 36 ........................................................................................

36 ...................................................................................................................................................................................

Warranty terms - Warranty terms 37 ...............................................................................................................

37 ...................................................................................................................................................................................

Back cover - Wallas - Spartan Air 38 ................................................................................................................

38 ...................................................................................................................................................................................