Contents

Crane Horizontal Motion | 4

CONTENTS

ABOUT THE MANUAL.................................................................................. 6

ABBREVIATIONS AND DEFINITIONS ......................................................................................................... 6

NUMERICAL REPRESENTATION ............................................................................................................... 6

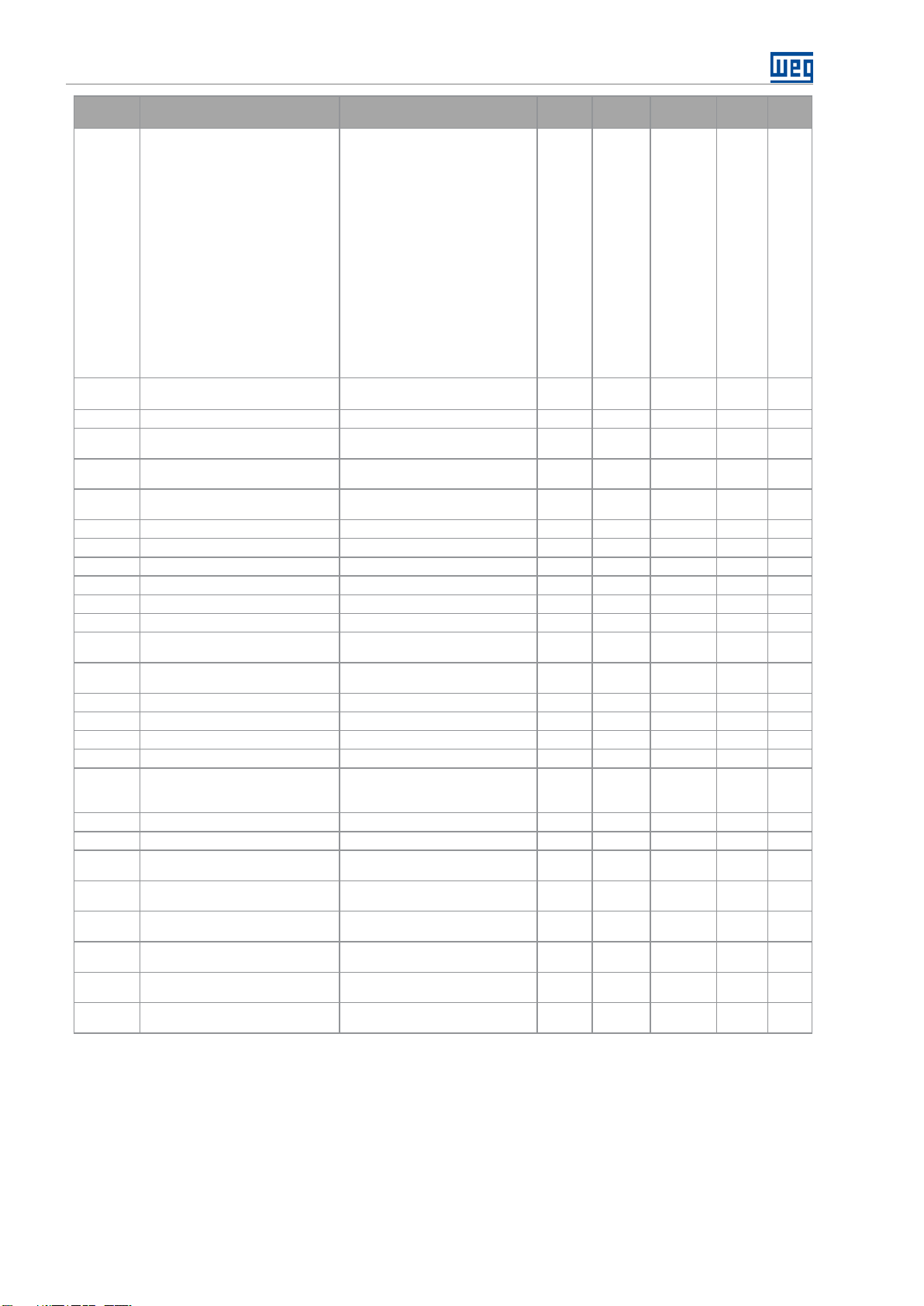

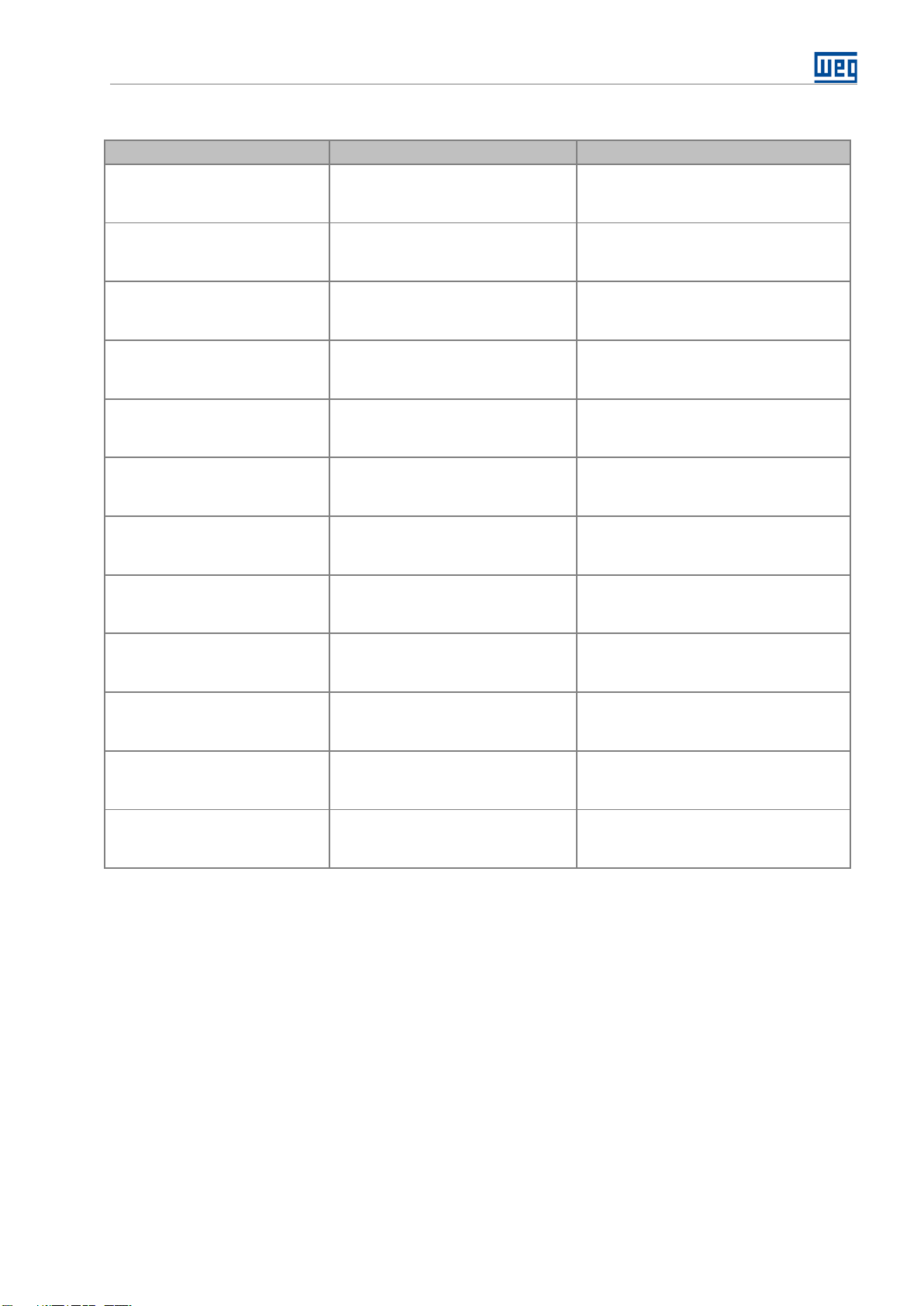

QUICK PARAMETER REFERENCE, FAULTS AND ALARMS .....................7

FAULTS AND ALARMS ................................................................................9

1 INTRODUCTION TO THE CRANE........................................................... 10

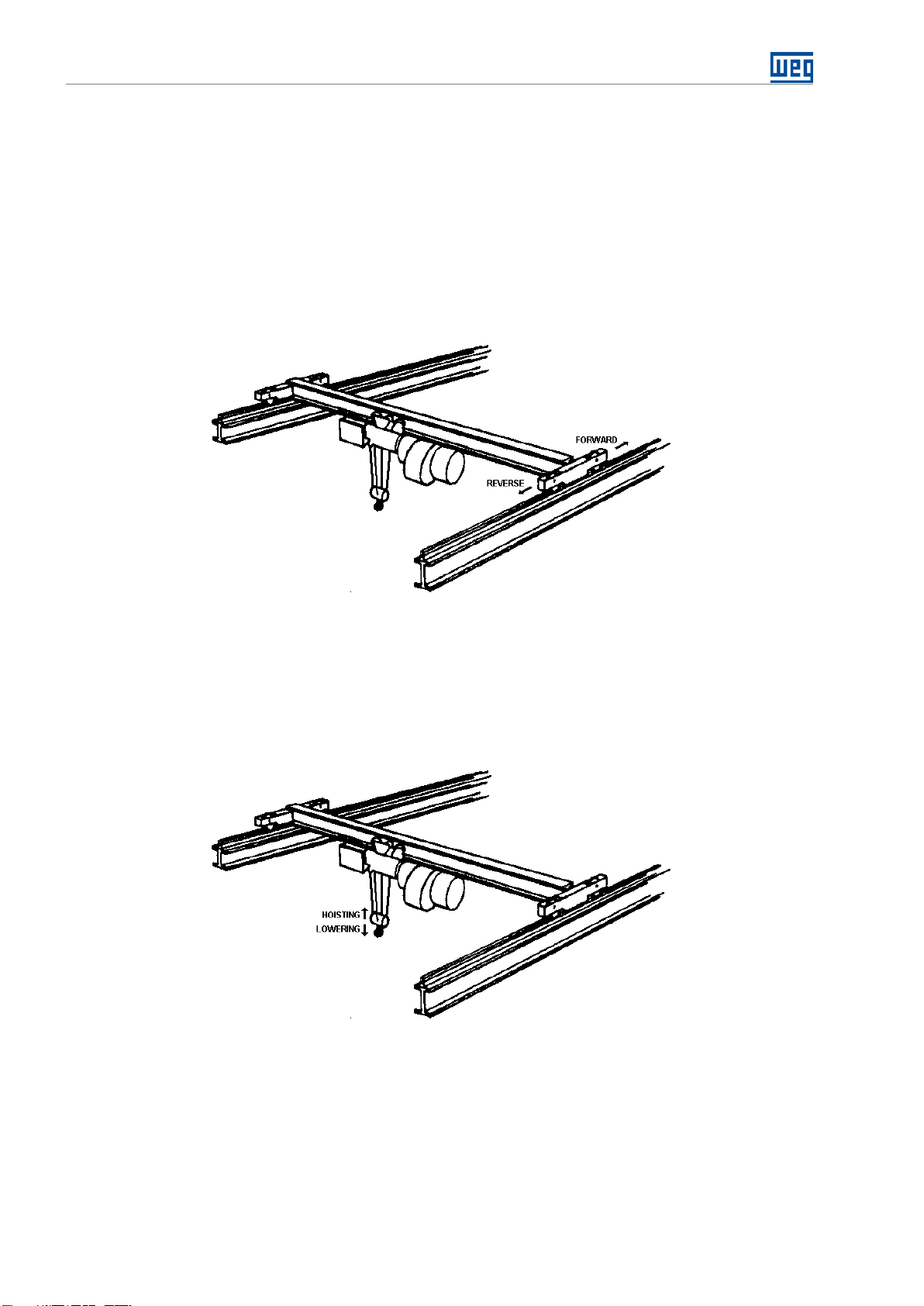

1.1 CRANE HORIZONTAL MOTION.......................................................................................................... 10

1.2 CRANE VERTICAL MOTION................................................................................................................ 10

1.3 FREQUENCY INVERTER USE ADVANTAGES ................................................................................... 11

1.4 PRECAUTIONS IN THE FREQUENCY INVERTER SELECTION ....................................................... 11

1.5 FREQUENCY INVERTER AND BRAKING RESISTOR SELECTION CRITERIA................................ 12

1.5.1 Horizontal Motion

.......................................................................................................................................12

1.5.2 Vertical Motion

............................................................................................................................................12

1.5.3 General Notes

..............................................................................................................................................13

2 CRANE HORIZONTAL MOTION ............................................................. 14

2.1 CONTROL CONNECTIONS ................................................................................................................. 14

2.1.1 Speed Reference via Electronic Potentiometer (EP)

.........................................................................15

2.1.2 Speed Reference via Digital Inputs

........................................................................................................16

2.1.3 Speed Reference via Analog Input AI1

.................................................................................................17

2.1.4 Speed Reference via Communication Networks

...............................................................................18

2.2 BRAKE SYSTEM................................................................................................................................... 19

2.2.1 Connection Diagram

..................................................................................................................................19

3 PARAMETERS DESCRIPTION ................................................................ 21

3.1 ORIGIN OF THE COMMANDS............................................................................................................. 21

3.1.1 Configuration of the Commands

............................................................................................................21

3.2 RAMPS .................................................................................................................................................. 23

3.3 SPEED LIMITS ...................................................................................................................................... 24

3.4 DYNAMIC BRAKING ............................................................................................................................ 25

3.5 SPEED REFERENCES.......................................................................................................................... 25

3.6 CONTROL WORD................................................................................................................................. 29

3.7 CONFIGURATION OF THE LIMIT SWITCHES.................................................................................... 29

3.8 DIGITAL INPUTS................................................................................................................................... 30

3.9 DIGITAL OUTPUTS............................................................................................................................... 35

3.10 ANALOG INPUT .................................................................................................................................. 36

3.11 LIGHTWEIGHT MODE ........................................................................................................................ 37

3.12 BRAKE CONTROL.............................................................................................................................. 40

3.13 MOMENTARY OVERLOAD ................................................................................................................ 45

3.14 INVERTER IN TORQUE LIMIT DETECTION ..................................................................................... 47

3.15 IMPROPER OPERATION ................................................................................................................... 48

3.16 MOTOR UMBALANCED CURRENT.................................................................................................. 49

3.17 HMI MONITORING ............................................................................................................................. 49

3.18 READ-ONLY PARAMETERS.............................................................................................................. 50

3.18.1 Alarm History

.............................................................................................................................................50

3.18.2 Status Word

...............................................................................................................................................51

4 CREATION AND DOWNLOAD THE APPLICATION................................ 53

5 DOWNLOAD DIALOG BOXES................................................................. 58

6 PROJECT TREE ON WLP........................................................................59