Specialized Concentrated Focused

Contents「VII」

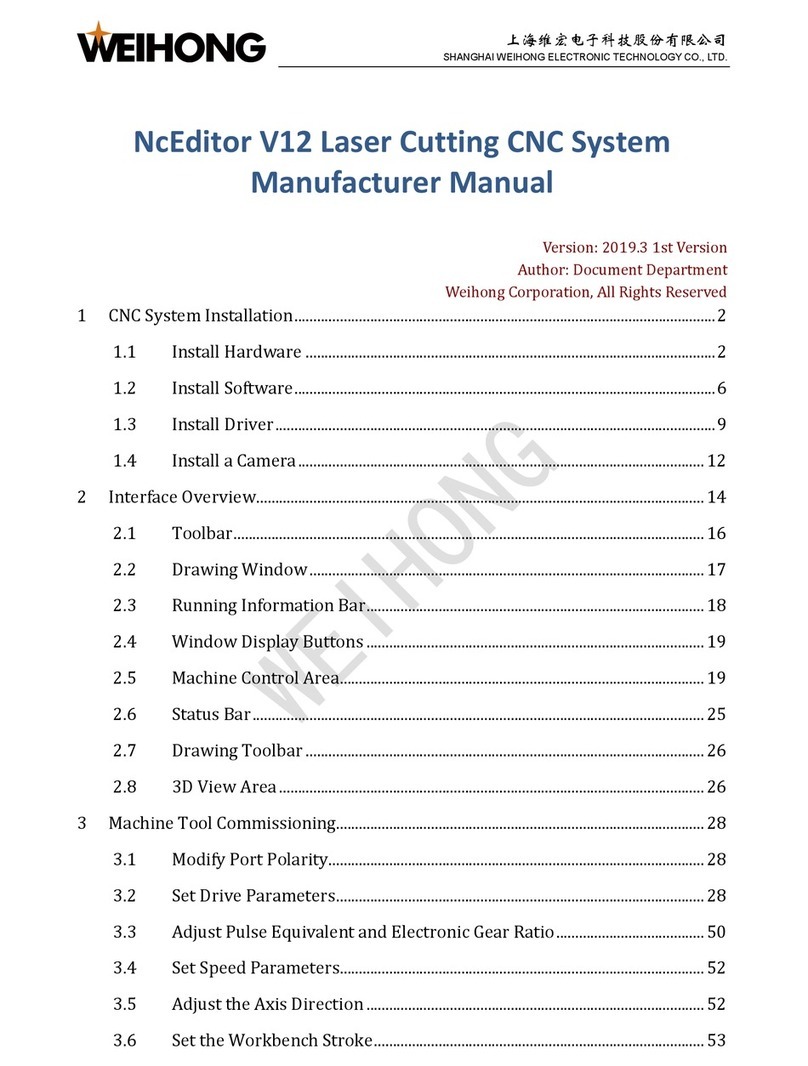

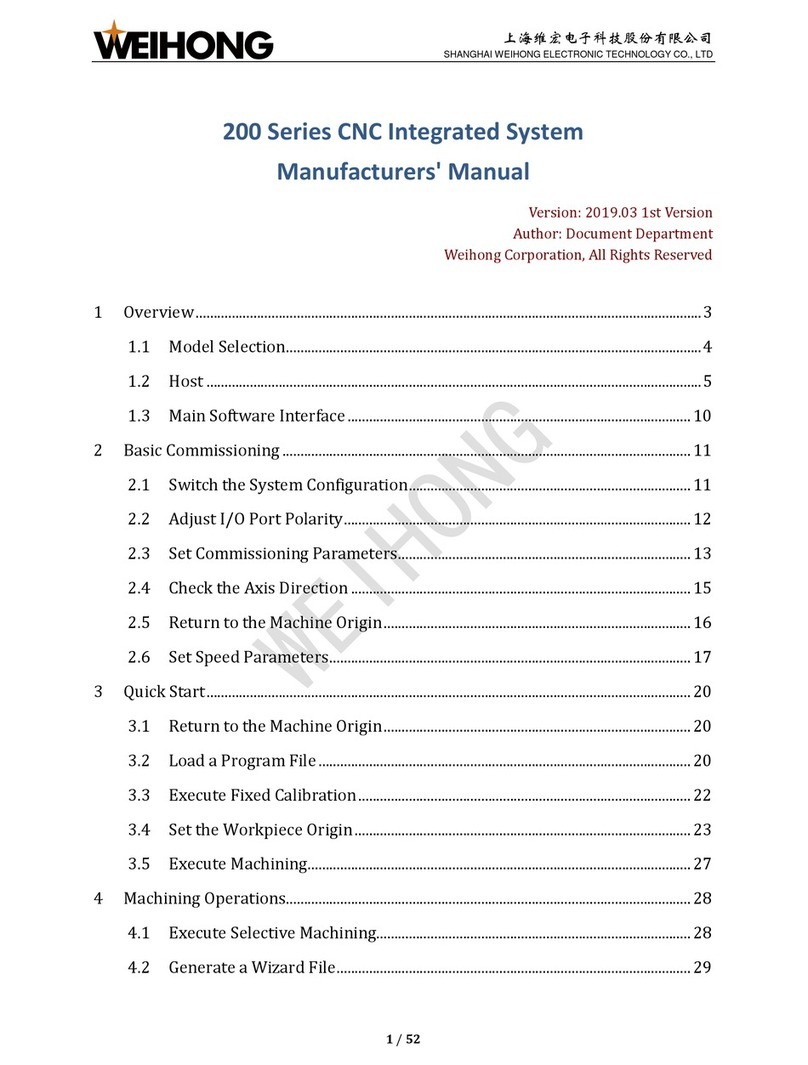

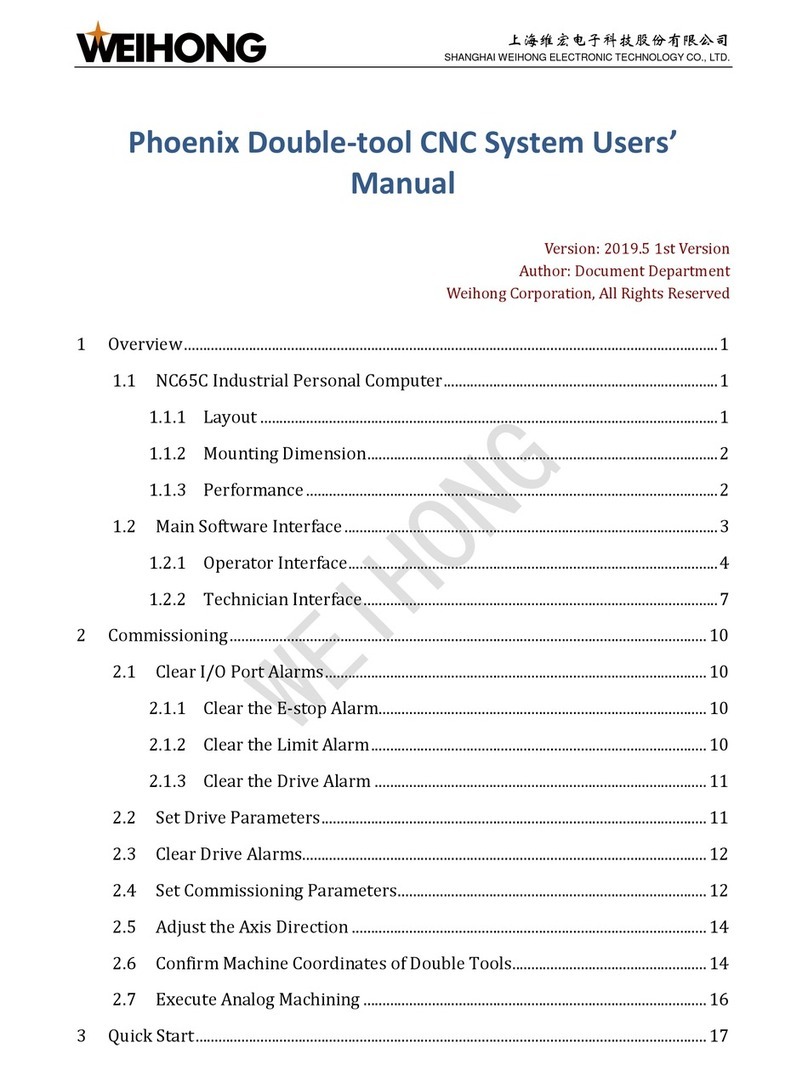

3.5.1. Local Files/USB Files............................................................................................................ 22

3.5.2. Operations............................................................................................................................. 22

3.5.3. Introduction to Parameters.................................................................................................... 25

3.5.4. Parameter Upkeep (Parameter Maintenance)...................................................................... 27

3.5.5. System Upkeep..................................................................................................................... 28

3.5.6. Diagnosis .............................................................................................................................. 31

4. Machining Operations.........................................................................................33

4.1. System Startup................................................................................................................33

4.2. Axis Direction Adjustment .............................................................................................33

4.3. Pulse Equivalent Adjustment.........................................................................................34

4.4. Setup of Machine Stroke................................................................................................36

4.5. Port Polarity Adjustment................................................................................................36

4.6. Back to Machine Origin..................................................................................................37

4.6.1. Parameter Setup of Backing to Machine Origin.................................................................... 38

4.6.2. Operation Mode of Backing to Machine Origin..................................................................... 38

4.7. Spindle Debugging .........................................................................................................39

4.7.1. Spindle Setup........................................................................................................................ 39

4.7.2. Park MCS Site....................................................................................................................... 39

4.7.3. Spindle Stop.......................................................................................................................... 40

4.8. Manual Machining...........................................................................................................41

4.8.1. Manual Selection of Manual Machining................................................................................ 41

4.8.2. Parameter Setting of Manual Machining............................................................................... 42

4.9. Automatic Machining......................................................................................................43

4.9.1. WCS Selection...................................................................................................................... 43

4.9.2. Load File ............................................................................................................................... 43

4.9.3. Set Workpiece Origin............................................................................................................ 44

4.9.4. Start Machining ..................................................................................................................... 45

4.10. Adjustment during Automatic Machining.....................................................................45

4.10.1. Feedrate Override Adjustment.............................................................................................. 45

4.10.2. Spindle Speed Adjustment.................................................................................................... 45

4.10.3. Machining Pause and Jiggle................................................................................................. 45