Start URL

1. Enter the Webserver IPAddress of

the target device to be connected.

2. Enter the Path or URL of the HTML

file name right after the “/” slash.

3. When resetting HMI or communication

failure happens, the seconds in which HMI

attempts the connection again can be set.

Info

Display HMI information, including

MicroBrowser version and firmware version.

Click ”Software Update” to update

MicroBrowser Version.

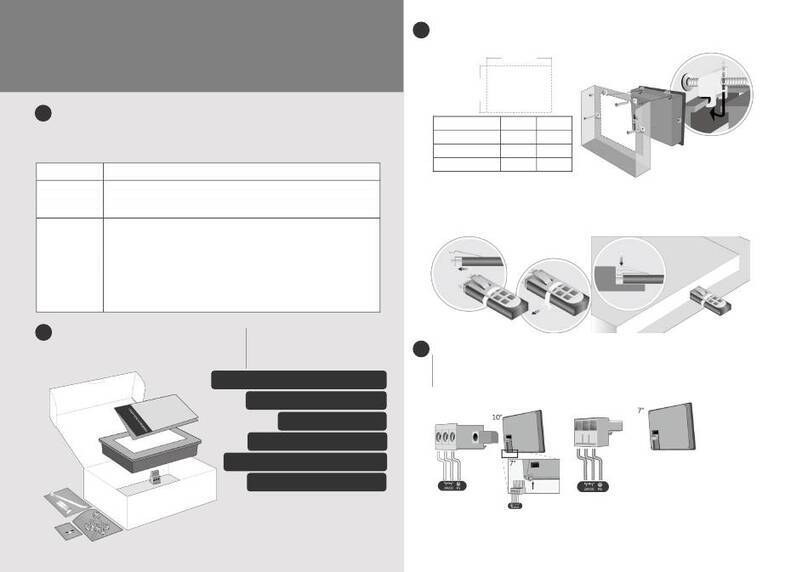

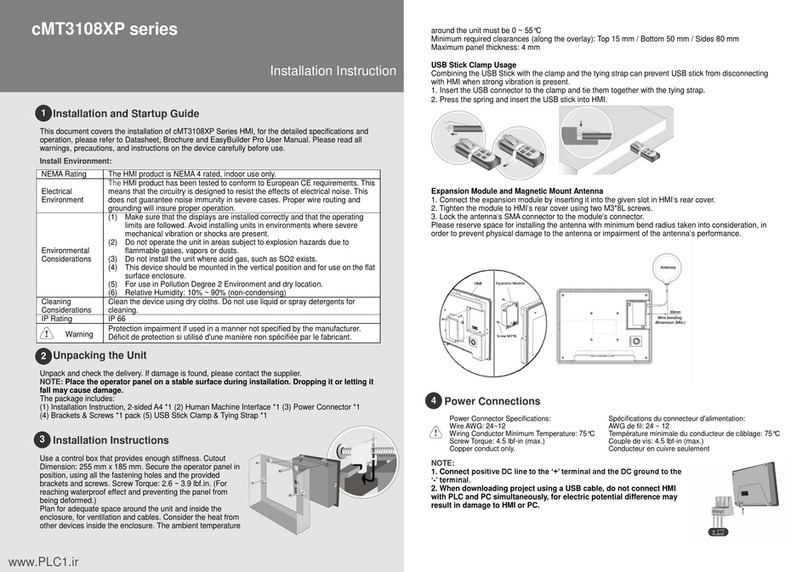

1. Insert a SD card into HMI, click

”Software Update” to start updating.

2. Or, after inserting SD card, switch ON

DIP SW3 and then reboot HMI.

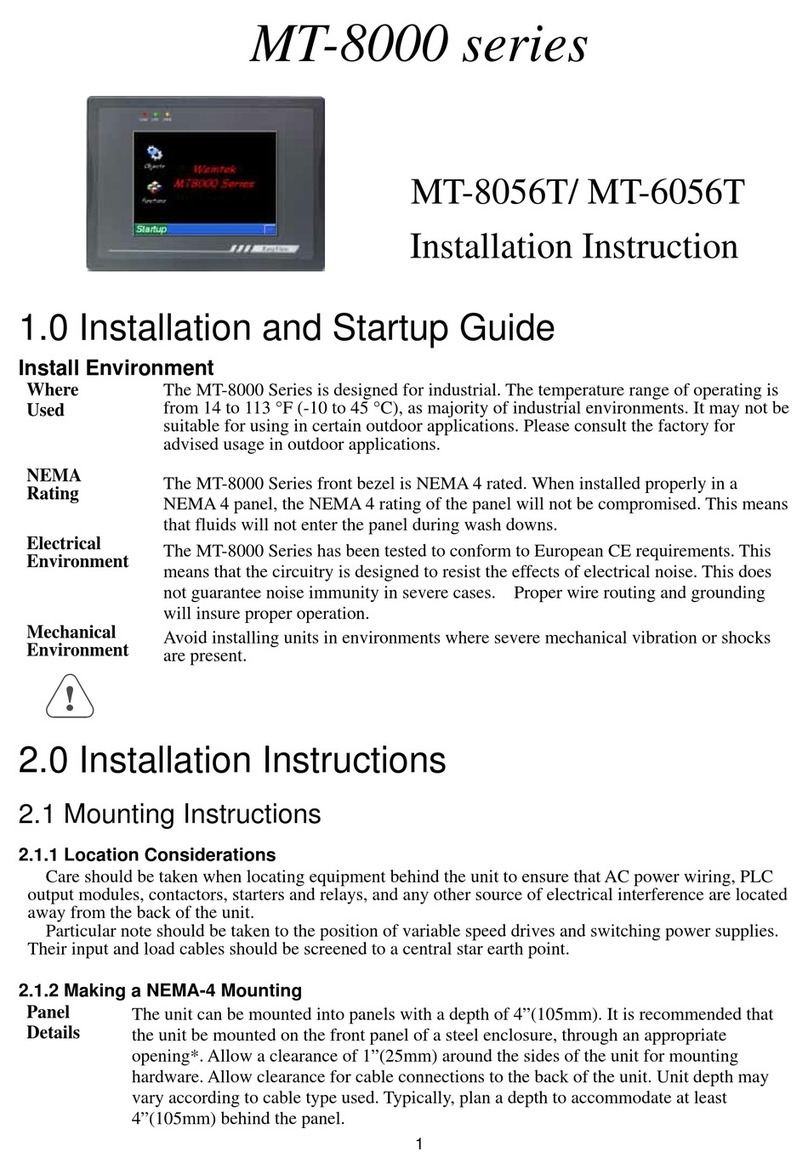

DIP SW Settings

The HMI can be powered by DC power only, voltage range: 24±20% Volts DC, compatible with

most controller DC systems. The power conditioning circuitry inside the unit is accomplished by

a switching power supply. The peak starting current can be as high as 2A.

If the display does not come on within 5 seconds of power up, remove power. An internal fuse

will prevent damage if the polarity of the DC power is incorrect. Check wiring for proper

connections and try to power up again.

An Internal fuse will prevent damage for over voltage condition however it isn’t guaranteed. DC

voltage sources should provide proper isolation from main AC power and similar hazards.

A Hard-wired EMERGENCY STOP should be fitted in any system using HMI to comply with ICS

Safety Recommendations.

Do not power the HMI and inductive DC loads, or input circuitry to the controller, with the same

power supply. Note: The 24 VDC output from some controllers may not have enough current to

power the HMI.

a. Wire lengths should be minimized (Max: 500m shielded, 300m unshielded).

b. Wires should be run in pairs with a neutral or common paired with a hot or signal line.

c. If wiring is to be exposed to lightning or surges, use appropriate surge suppression devices.

d. Keep AC, high energy, and rapidly switching DC wiring separate from signal wires.

e. Equip ungrounded DC supplies with a resistor and capacitor in parallel to earth ground.

This provides a path for static and high frequency dissipation. Typical values to use are 1MOhm

and 4700pF.

The system designer should be aware that devices in Controller systems could fail and thereby

create an unsafe condition. Furthermore, electrical interference in an operator interface can lead

to equipment start-up, which could result in property damage and/or physical injury to the

operator.

If you use any programmable control systems that require an operator, be aware that this

potential safety hazard exists and take appropriate precautions. Although the specific design

steps depend on your particular application, the following precautions generally apply to

installation of solid-state programmable control devices, and conform to the guidelines for

installation of Controllers recommended in NEMA ICS 3-304 Control Standards.

Programming

Considerations

To conform with ICS Safety Recommendations, checks should be placed in the controller to

ensure that all writable registers that control critical parts of plant or machinery have limit

checks built into the program, with an out-of-limit safe shut down procedure to ensure safety of

personnel. GME60IWP0_MT605_607_610iWPV1WK_Installaiton_120525

Limited Warranty

This product is limited warranted against defects in design and manufacture. The proven

defective product will either be repaired or replaced, at Weintek’s discretion. This warranty

shall not cover any product which is

(a) Out of warranty period which is 1 year from the date of purchase.

(b) Damage caused by Force Majeure, accident, negligence, improper installation or misuse.

(c) Product has been repaired or taken apart by unauthorized technicians.

(d) Products whose identification markings have been removed or damaged.

NOTE:

Make sure that all local and national electrical standards are met when installing

the unit. Contact your local authorities to determine which codes apply.

NOTE: Make sure that all local and national electrical standards are met when

installing the unit. Contact your local authorities to determine which codes apply.

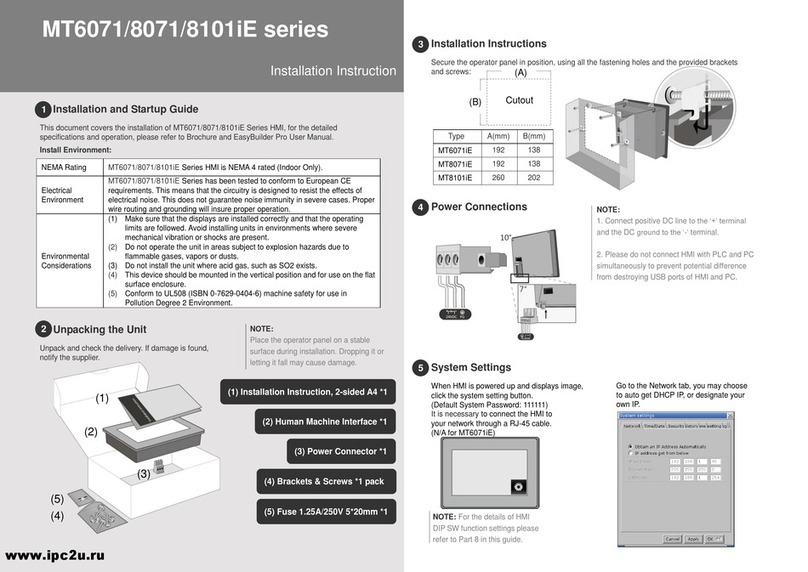

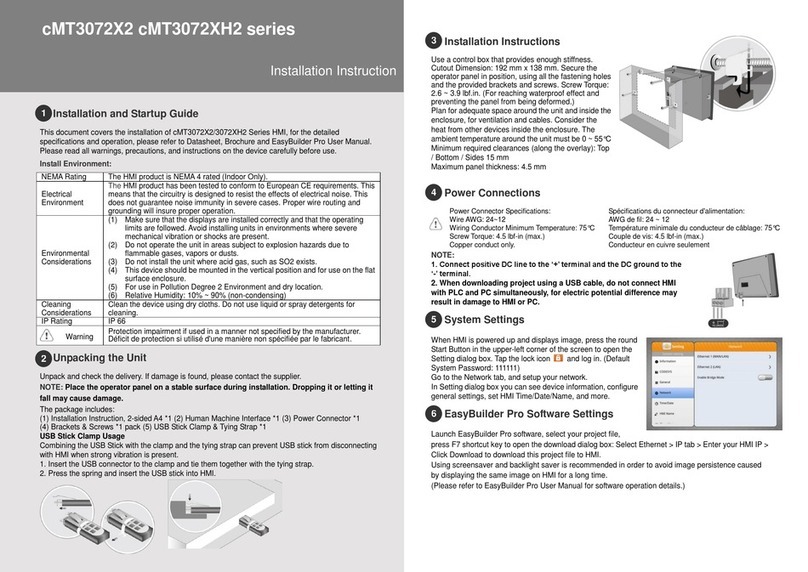

Touch Screen Calibration Mode

Hide HMI System Setting Bar

MT607iWP/MT610iWP Normal

MT605iWP Must stay OFF

MT605iWP Normal

MT607iWP/MT610iWP Must stay OFF

NOTE:

Since MT605iWP (4.3”) does not support

SD card, to update MicroBrowser version,

please contact your distributor.