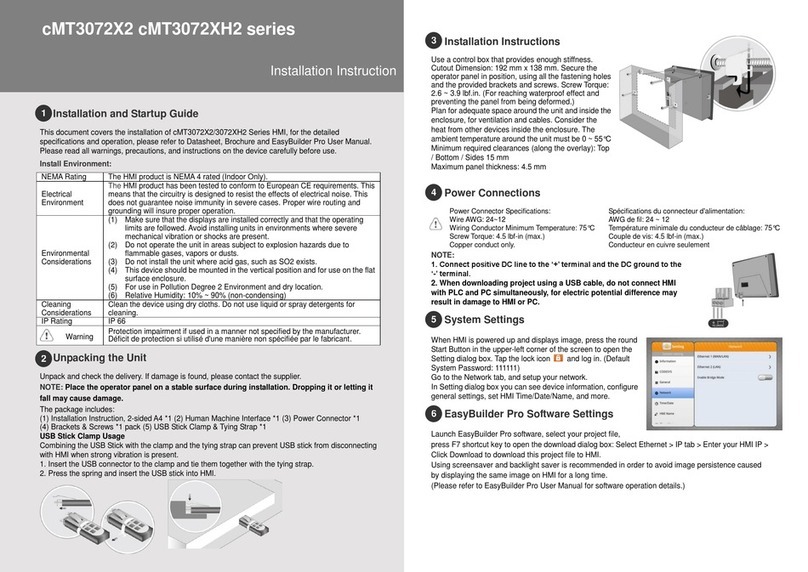

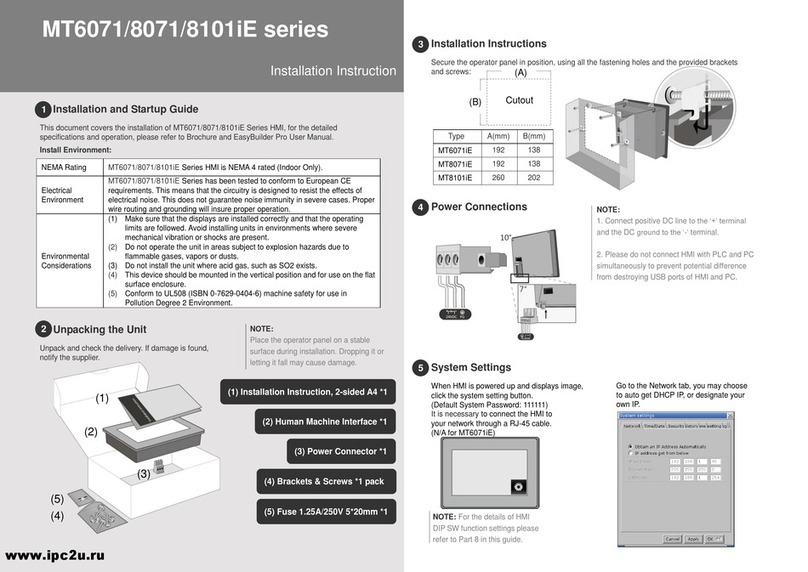

EasyBuilder Pro Software Settings

Launch EasyBuilder Pro software, select your project file, press F7 shortcut key to open the download

dialog box: Select Ethernet > IP tab > Enter your HMI IP > Click Download to download this project

file to HMI.

If use MT6071iE, please select USB cable.

Using screensaver and backlight saver is recommended in order to avoid image persistence caused

by displaying the same image on HMI for a long time.

( Please refer to EasyBuilder Pro User Manual for software operation details )

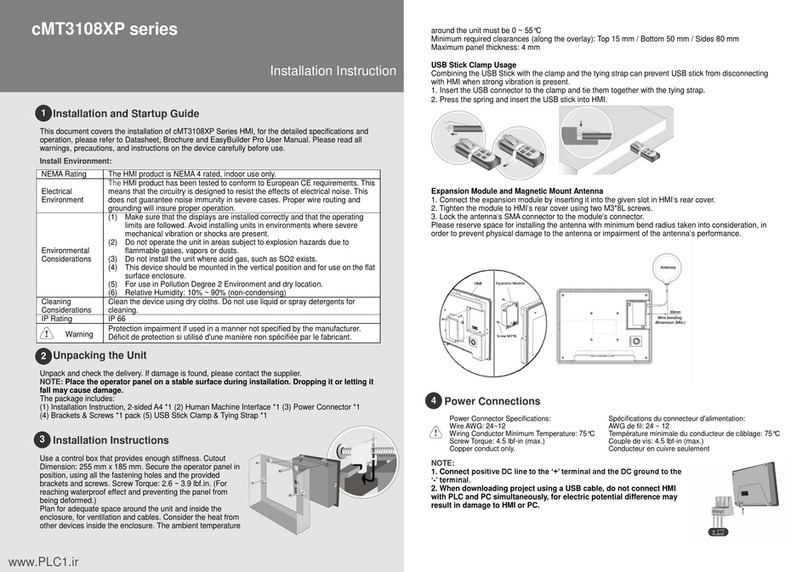

Communication Connections

NOTE: COM2 and COM3 [RS485] 2W support MPI 187.5K, please use one at a time.

COM1 [RS232] 9 Pin, Male, D-sub COM2 / COM3 [RS485] 9 Pin, Female, D-sub

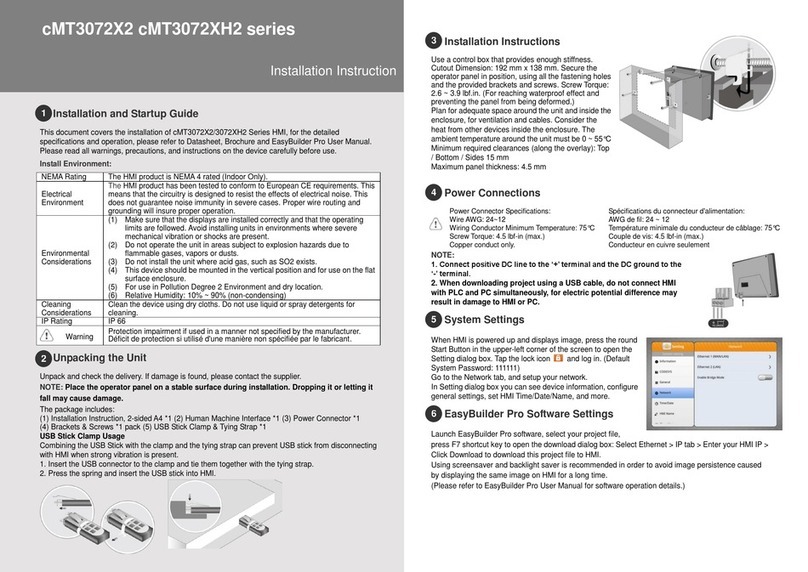

DIP SW Settings

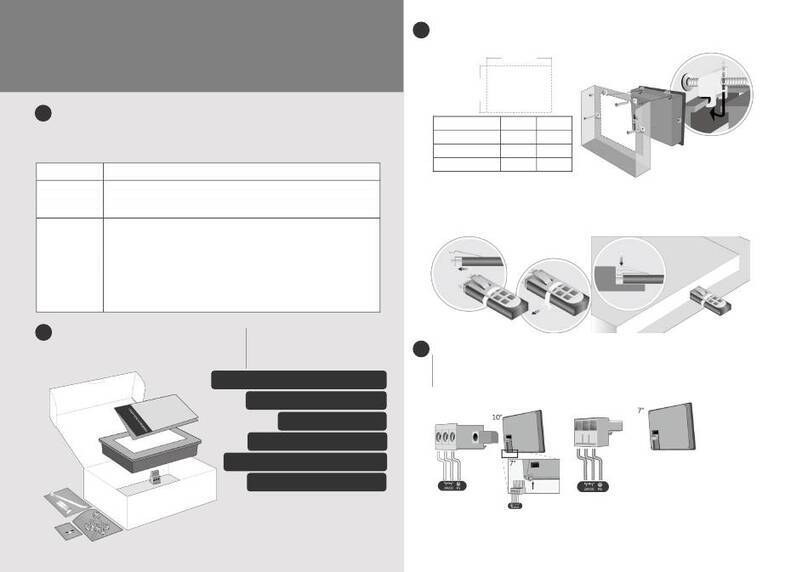

Battery Replacement

Battery replacement shall be performed by qualified personnel only and care must be taken when

handling lithium batteries.

Limited Warranty

This product is limited warranted against defects in design and manufacture.

The proven defective product will either be repaired or replaced, at Weintek’s discretion.

This warranty shall not cover any product which is

(a) Out of warranty period which is 12 months from the manufacturing month of the HMI products.

(b) Damage caused by Force Majeure, accident, negligence, improper installation or misuse.

(c) Product has been repaired or taken apart by unauthorized technicians.

(d) Products whose identification markings have been removed or damaged.

NOTE:

Make sure that all local and national electrical standards are met when installing

the unit. Contact your local authorities to determine which codes apply.

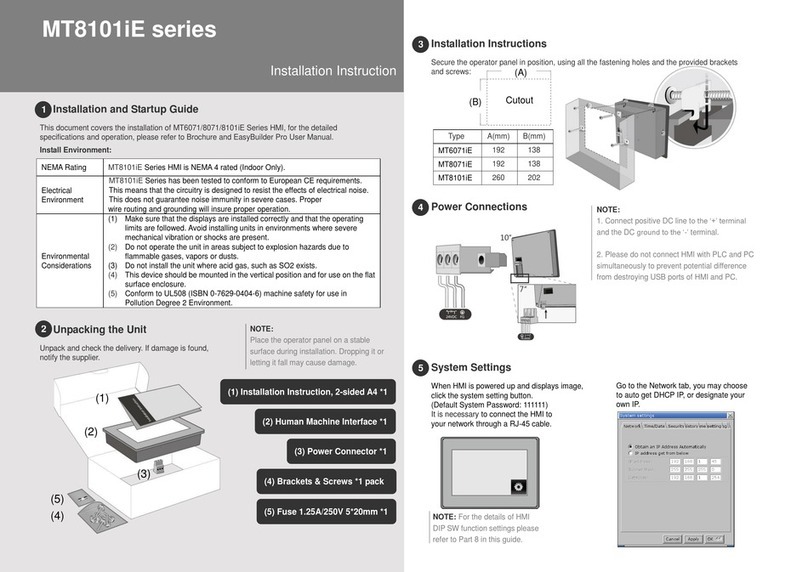

Touch Screen Calibration Mode

Hide HMI System Setting Bar

Another way to enter touch screen calibration mode: Press and hold

anywhere on the screen for more than 2 seconds when HMI starts.

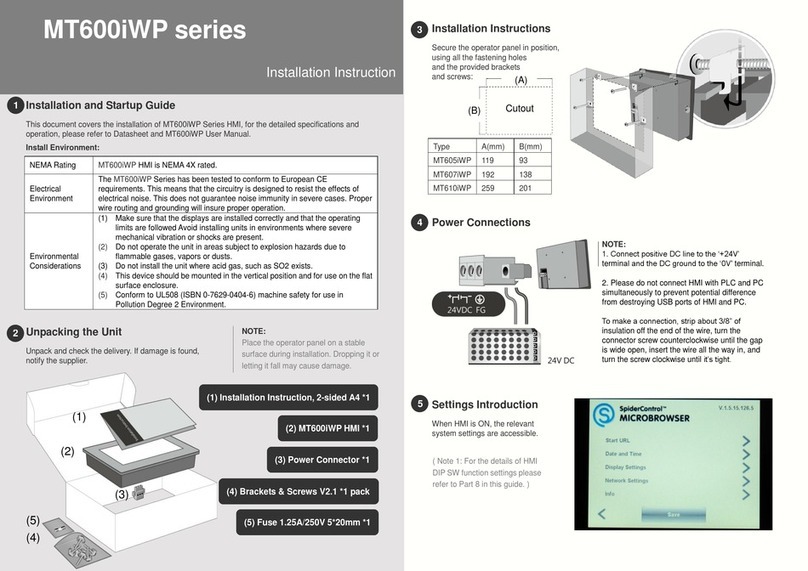

The unit can be powered by DC power only, voltage range: 24±20% Volts DC, compatible with

most controller DC systems. The power conditioning circuitry inside the unit is accomplished by a

switching power supply. The peak starting current can be as high as 2A.

If the display does not come on within 5 seconds of power up, remove power.An internal fuse will

prevent damage if the polarity of the DC power is incorrect. Check wiring for proper connections

and try to power up again.

An Internal fuse will prevent damage for overcurrent condition however it isn’t guaranteed. DC

voltage sources should provide proper isolation from main AC power and similar hazards.

A Hard-wired EMERGENCY STOP should be fitted in any system using HMI to comply with ICS

Safety Recommendations.

Do not power the unit and inductive DC loads, or input circuitry to the controller, with the same

power supply. Note: The 24 VDC output from some controllers may not have enough current to

power the unit.

a. Power wire length should be minimized (Max: 500m shielded, 300m unshielded).

b. Please use twisted pair cables for power wire and signal wire and conform to the impedance

matching.

c. If wiring is to be exposed to lightning or surges, use appropriate surge suppression devices.

d. Keep AC, high energy, and rapidly switching DC power wiring separated from signal wires.

e. Add a resistor and capacitor in the parallel connection between the ungrounded DC power

supply and the frame ground. This provides a path for static and high frequency dissipation.

Typical values to use are 1M Ohm and 4700pF.

NOTE: Make sure that all local and national electrical standards are met when

installing the unit. Contact your local authorities to determine which codes apply.

The system designer should be aware that devices in Controller systems could fail and thereby

create an unsafe condition. Furthermore, electrical interference in an operator interface can lead to

equipment start-up, which could result in property damage and/or physical injury to the operator.

If you use any programmable control systems that require an operator, be aware that this potential

safety hazard exists and take appropriate precautions. Although the specific design steps depend on

your particular application, the following precautions generally apply to installation of solid-state

programmable control devices, and conform to the guidelines for installation of Controllers

recommended in NEMA ICS 3-304 Control Standards.

Programming

Considerations

To conform with ICS Safety Recommendations, checks should be placed in the controller to ensure

that all writable registers that control critical parts of plant or machinery have limit checks built into

the program, with an out-of-limit safe shut down procedure to ensure safety of personnel.

GME6871E0_MT6071_8071_8101iE1_Installation_170516

NOTE:

Make sure that all local and national electrical standards are met when installing

the unit. Contact your local authorities to determine which codes apply.

Pobrano z: https://panele-hmi.pl/panel-operatorski-hmi-10-weintek-mt8101ie