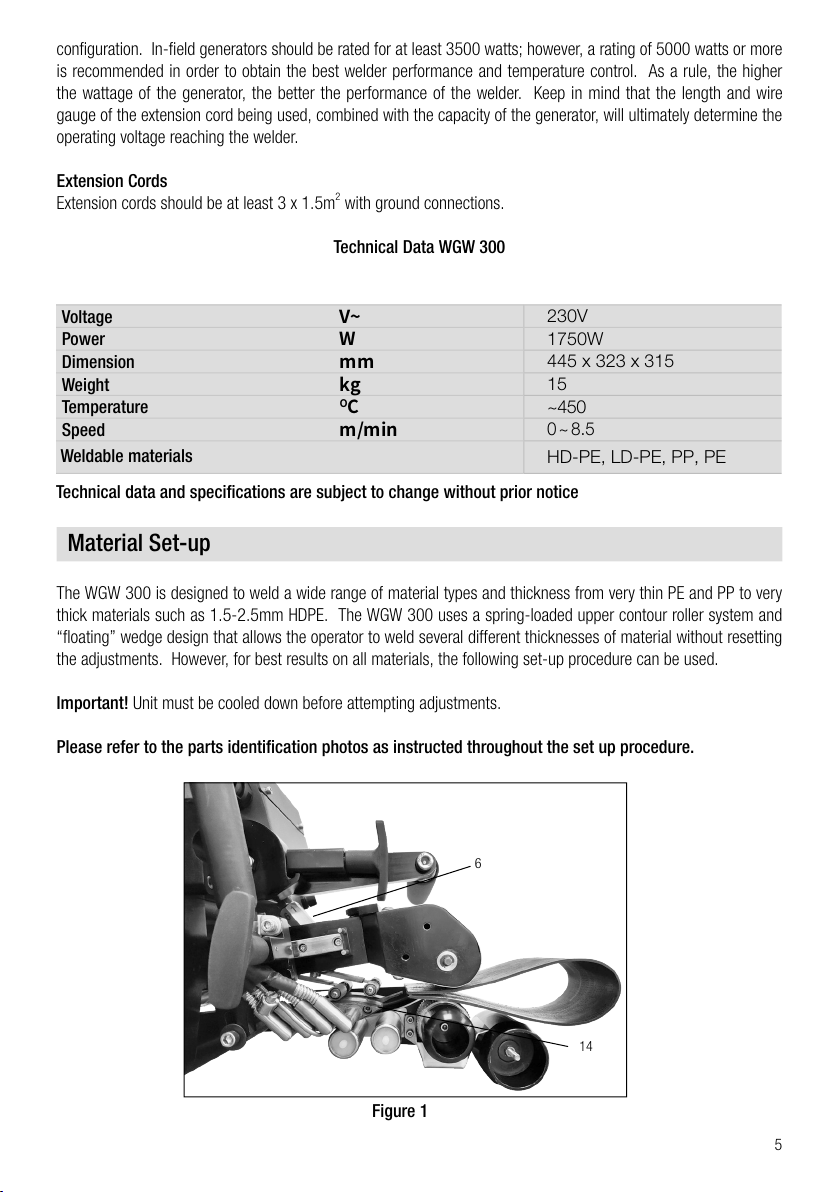

6

Set-up Nip Pressure Adjustment:

Adjustment Location:

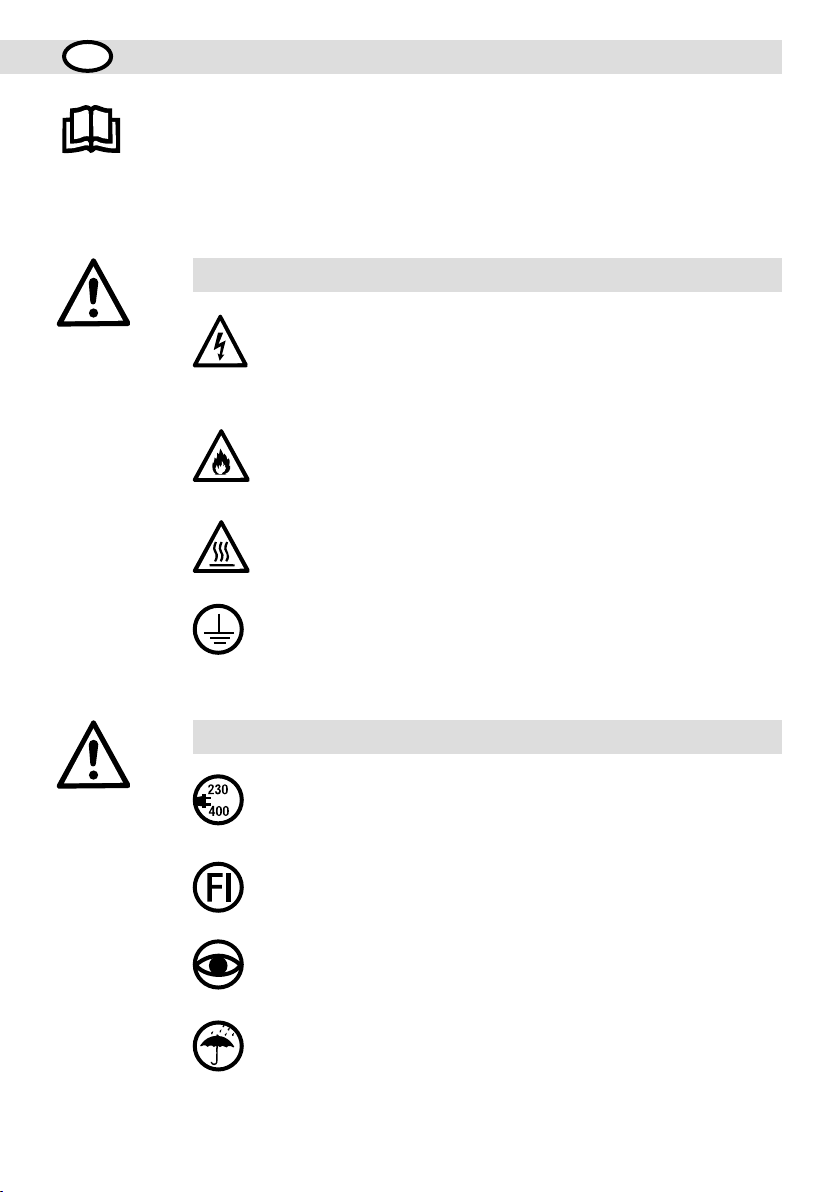

The nip pressure adjustment is located between the nip lever and upper nip arm; it is a hex shaped turnbuckle

style nut (#6, Figure 1).

The correct amount of nip pressure is needed to get a good weld. It is also important that the nip rollers are

providing enough traction to keep the WGW 300 from “burning out”. This can happen when the nip rollers lose

traction and spin on the material, causing the WGW 300 to stop in the seam and burn a hole in the material.

Note: Pressure Adjustment for thin material and geotextiles:

These materials require less nip pressure. Too much pressure can cause the material to perforate at the edge of

the seam causing a “zipper” effect.

• Make sure the heating wedge (#14, Figure 1) is in the disengaged position.

• Turn the nip pressure adjustment hex nut clockwise while looking down from above several turns, raising the

nip arm up to give a fresh starting point for this adjustment. (Loosen set screw(s) on hex nut first if present to

avoid damaging threads on eye bolts)

• Place one end (one thickness) of your adjustment material between the nip rollers and into the unit about 1”

inch. Engage nip rollers by pushing down on the nip lever until it has “clicked” into place and is held in position

by the lock pin. At this point the material should move around freely between the nip rollers.

• Turn the hex nut (#6, Figure 1) counter clockwise until the nip rollers begin to pinch down on the material and

you cannot turn the nut by hand anymore. This zeroes the adjustment.

• Disengage nip rollers and turn the hex nut counter clockwise one full rotation.

• Insert the adjustment material (the opposite end of the fold, two thicknesses) between the nip rollers and

engage nip rollers together until the lock pin clicks into its detent as shown on the Figure 1. Check pressure

by attempting to move the material side to side. If you are able to move the material or pull the material

straight out without the nip rollers turning, disengage the nip pressure and turn adjustment nut (#6, Figure 1)

counter clockwise ¼ turn at a time until the desired pressure is reached. Remember to tighten the set screw(s)

on the adjustment nut after you have completed adjustment of the nip pressure to prevent the pressure from

backing off while welding.

Note: When the nip pressure adjustment is set correctly, engaging the nip pressure lever should take some effort

but it should feel like a smooth motion. Again, it is important that you are getting enough traction to avoid burning

out and at the same time providing enough nip pressure to create a good weld. Keep in mind that the thicker the

material being welded and especially textured material, the greater the pressure should be.