ECJ002S Calibration Check

I.

Disconnect soldering tool

from

the tool receptacle on the power unit and connect

to

the

receptacle

on

th

e

WC

1000 Calibration Reference Unit. Connect the

WC

I000

to

the tool receptacle on the power unit aod select resistor

"8"

.

CAUTION: The power unit should not be turned above 350°F (175

c-

C)

for

more

than l m

inut\!

with the tool connected

to

the WCI000 to prevent damage

to

the

tool heating element.

2.

Rotate temperature set knob fully CCW and

turn

power unit on. Indicator lamps

on

we

I000 should

be

out. Allow 30 minute warm-up before continuing.

3. Rotate temperature

se

t knob fully

ew

, indicator lamps should

be

full

on.

4.

Rotate temperature set knob

cew

until indicator lamps start

fl

as

hing,

note

temperature

se

tting. Continue rotating temperature set knob

cew

until lamps

ju

st

stop flashing. Temperature set should equal 745°F ±

10

(395°C

:!-

6)

a

nd

the

indicator lamps shou

ld

have started flashing approximately 35°F (

19

c-

C) higher.

5. Select resistor "A" on

th

e

We

I

000

Calibration Reference

Uni

t.

6. Rotate temperature set knob

ecw

until indicator la

mp

s just stop

fl

as

hin

g.

Temperature set should equal 395°F ±l0 (200"C ±6).

7. Ifcalib

ra

tion

is

out

of

tolerance, perfonn there-calibration procedure.

ECJ002S

Tip Temperature Calibration Procedure

1.

Monitor the t

ip

temperature with a 30 gauge thermocouple resistance welded

to

the center

of

the wetted area, tinning should be removed before welding.

K-Ill

,

K-121, and

K-131

temperature test kits are recommended: see Replacement parts

and Accessories section.

2.

Se

t the temperature set knob

to

t

he

desired temperature and allow the tip

temperature

to

stabilize.

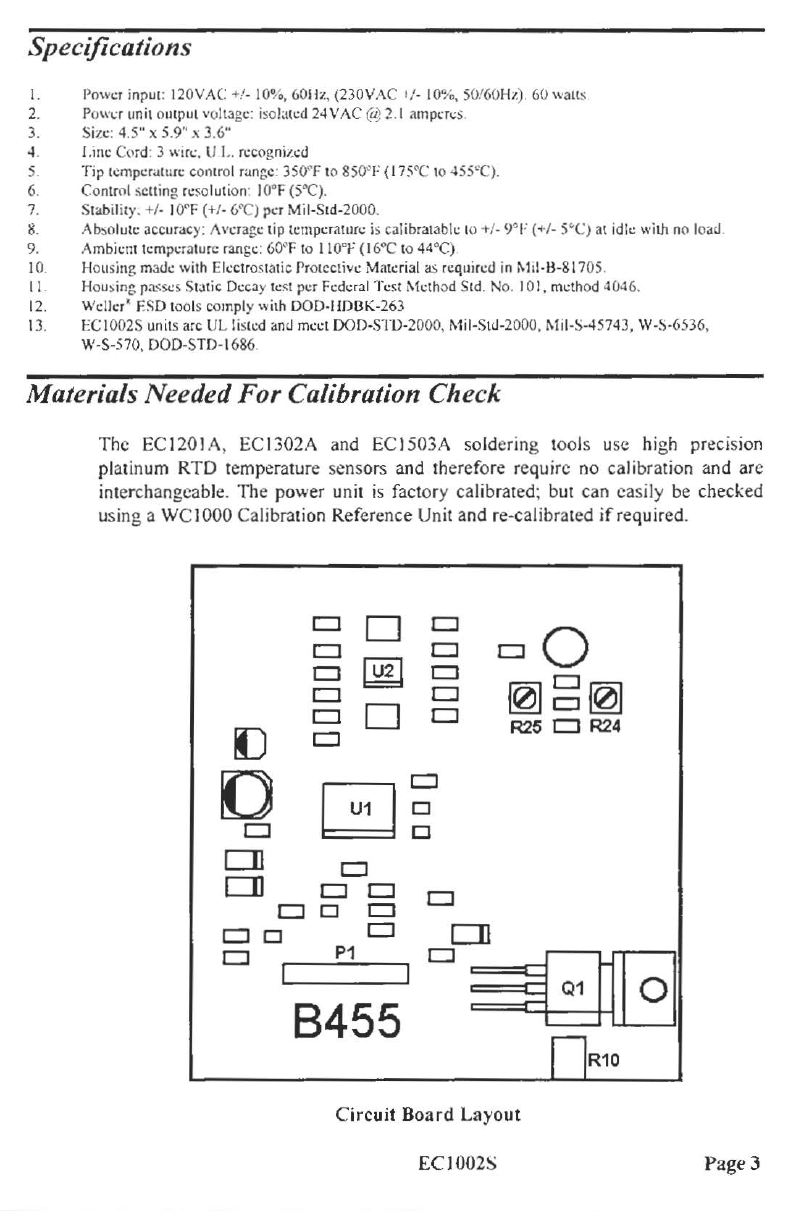

3. Adjust RI

0,

accessible through the hole

in

the station bottom directly

be

l

ow

the

temperature set knob. until the indicated tip temperature matches the

se

t

temperature.

ECJ002S Re-calibration Procedure

Because the power unit must

be

dis-assembled to gain access

to

the calibration

adjustments, this procedure is not recommended unless the Calibration Check

is

performed

and

re-calibration

is

indicated.

CAUTION: Disconnect power cord before

di

s-assembling power unit.

I. Remove 4 rubber feet

and

sc

rews under feet; remo

ve

top cover

from

station.

Page 4 ECI002S