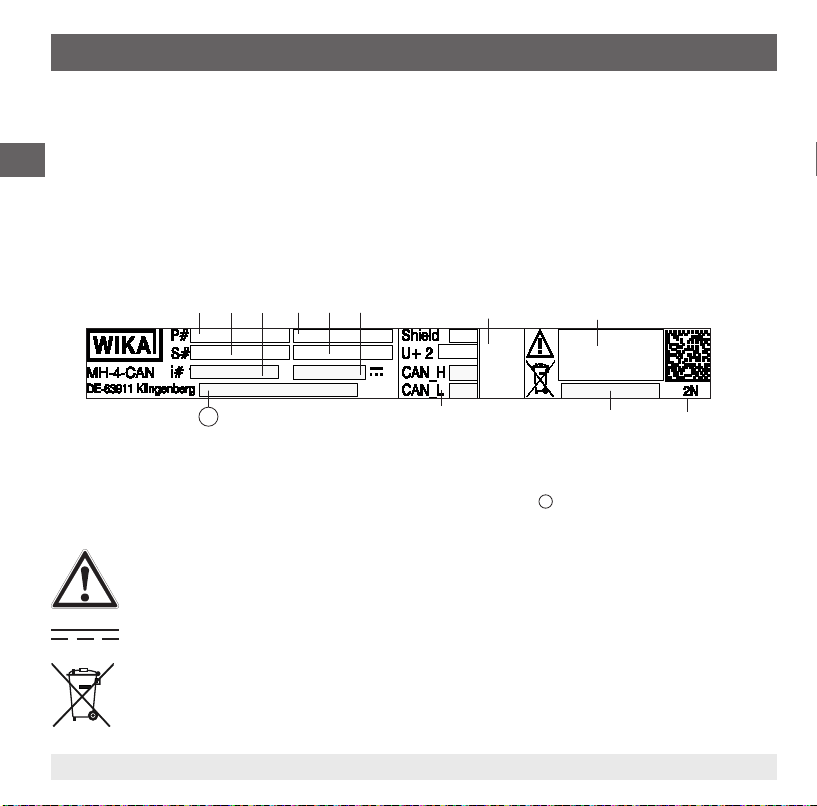

5WIKA operating instructions pressure sensor, model MH-4-CAN

EN

14495737.01 03/2023 EN/DE/FR/ES

3. Safety

Information

The signal word points out useful tips, recommendations and information for ecient and trouble-free

operation.

3.2 Intended use

The pressure sensor may only be used in such applications as are within its technical performance limits, in particular

with regard to its material resistance limit, leakage rate limits and permissible temperature and pressure limits.

It is the sole responsibility of the manufacturer or operator of a machine or plant to ensure the suitability of the pressure

sensor, and its media resistance, within the application through proper choice of materials and maintenance cycles.

→ For performance limits, see chapter 8 “Specications”

The mounting, dismounting, installation, parameterisation and maintenance of the pressure sensor in industrial

environments absolutely requires suitably skilled personnel in accordance with chapter 3.4 “Personnel qualication”.

The model MH-4-CAN has been developed for the pressure measurement of non-hazardous uids, liquids and gases

(classication in accordance with Directive 2014/68/EU Article 13, Regulation (EC) No. 1272/2008, or GHS1)) which

are mainly used for cooling, lubrication, cleaning or power transmission in industrial machines.

The instrument has been designed and built solely for the intended use described here, and may only be used

accordingly.

The manufacturer shall not be liable for claims of any type based on operation contrary to the intended use.

3.3 Improper use

Any use beyond or dierent to the intended use is considered as improper use.

The following points, in particular, count as improper use and are not permissible:

■Use of this instrument in safety or emergency shutdown devices

■Unauthorised modications to the pressure sensor

■Use in hazardous areas

■Use with abrasive and viscous media

■Use for refrigeration and air-conditioning applications

■Use in water pumps