11116552.09 EN/DE 05/2016

8WIKA Operating instructions, E-10, E-11

EN

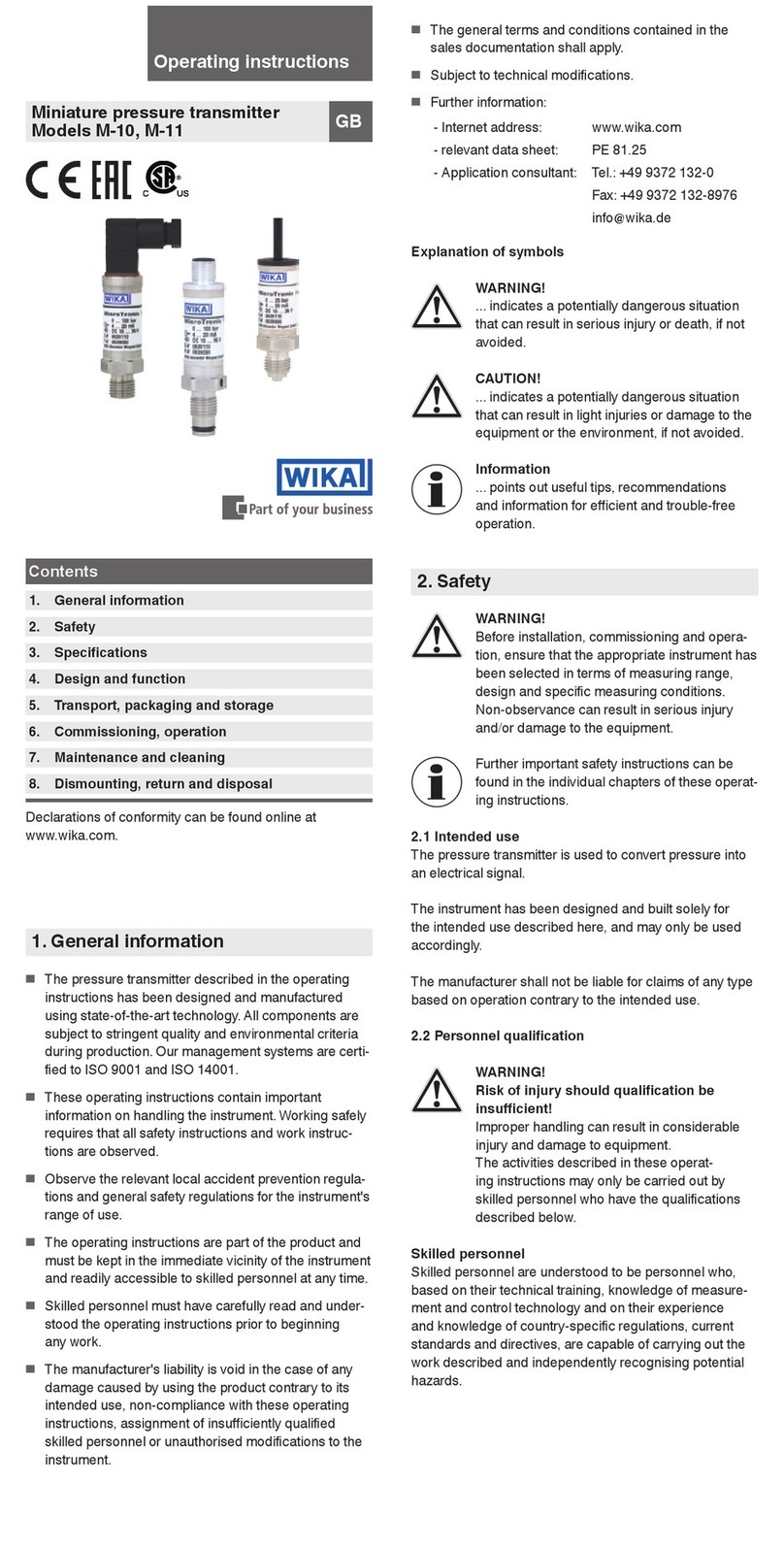

4. For your safety

WARNING

■

Select the appropriate pressure transmitter with regard to scale range, perfor-

mance and specic measurement conditions prior to installing and starting the

instrument.

■

Observe the relevant national regulations and observe the applicable

standards and directives for special applications (e.g. with dangerous media

such as acetylene, ammable gases or liquids and toxic gases or liquids and

with refrigeration plants or compressors). If you do not observe the appropriate

regulations, serious injuries and/or damage can occur!

■

Open pressure connections only after the system is without pressure!

■

Please make sure that the pressure transmitter is only used within the overload

threshold limit all the time!

■

Observe the ambient and working conditions outlined in section 6 table „Speci-

cations”.

■

Ensure that the pressure transmitter is only operated in accordance with the

provisions i.e. as described in the instructions.

■

Do not interfere with or change the pressure transmitter in any other way than

described in these operating instructions.

■

Remove the pressure transmitter from service and mark it to prevent it from

being used again accidentally, if it becomes damaged or unsafe for operation.

■

Take precautions with regard to remaining media in removed pressure transmit-

ter. Remaining media in the pressure port may be hazardous or toxic!

■

Have repairs performed by the manufacturer only.

4. For your safety