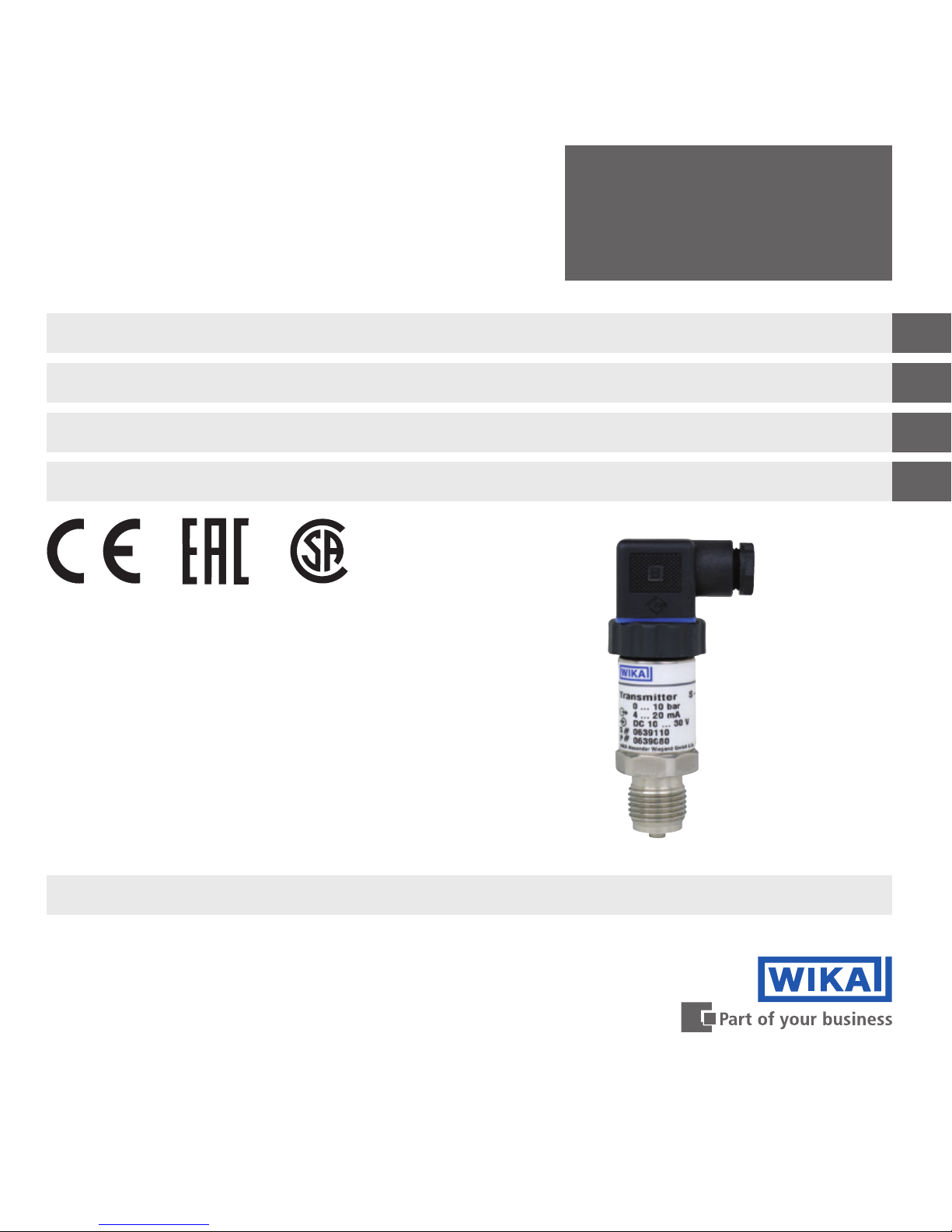

EN

10 WIKA operating instructions pressure transmitter, model S-10

1604457.16 09/2017 EN/DE/FR/ES

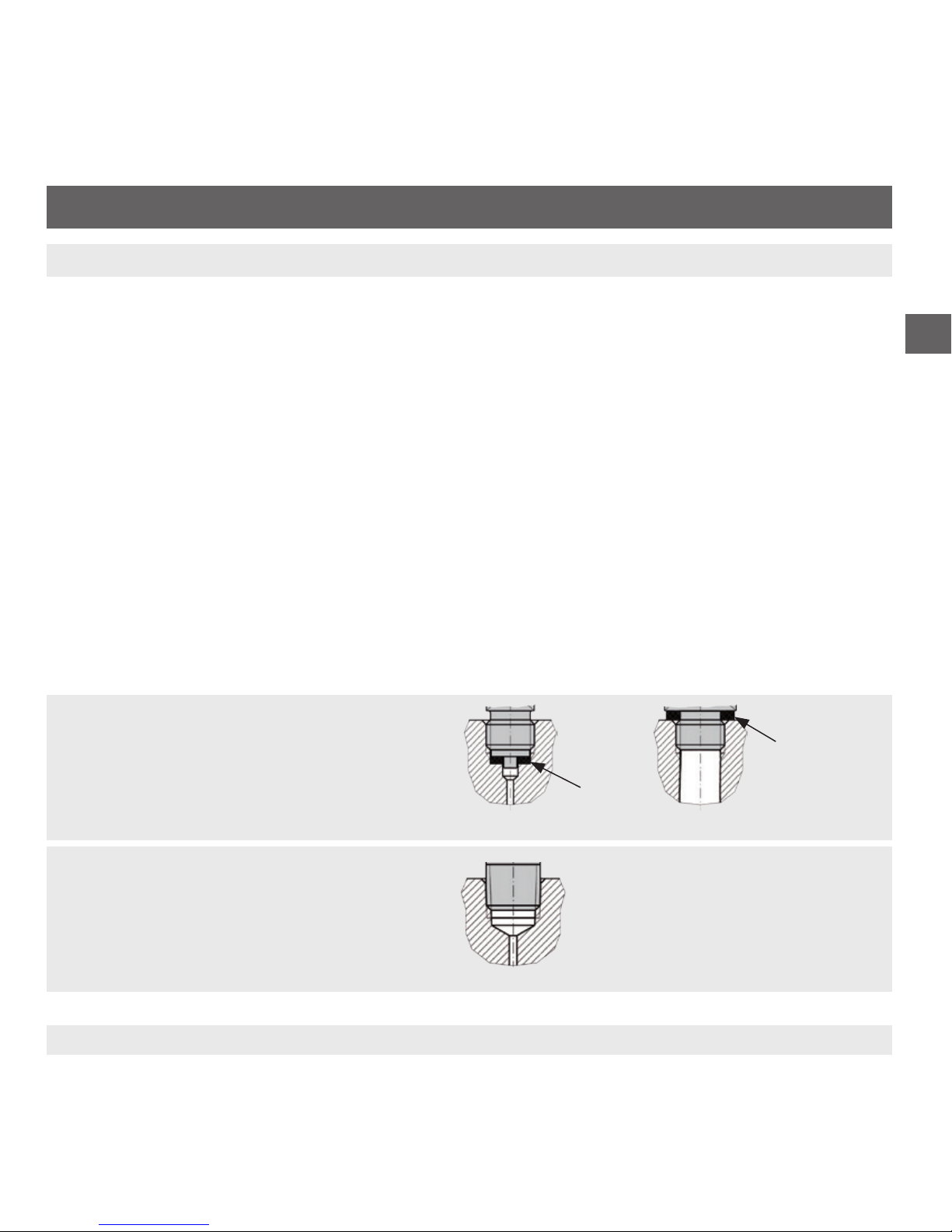

Mounting the instrument

The max. torque depends on the mounting point (e.g. material and shape). If you have any questions,

please contact our application consultant.

→ For contact details, see chapter 1 “General information” or the back page of the operating instructions.

1. Seal the sealing face (→ see “Sealing variants”).

2

.

At the mounting point, screw the pressure transmitter in hand-tight.

3

.

Tighten with a torque spanner using the spanner ats.

5.2 Connecting the instrument to the electric system

Requirements for voltage supply

→ For power supply, see product label

The power supply for the pressure transmitter must be made via an energy-limited electrical circuit in accordance

with section 9.4 of UL/EN/IEC 61010-1, or an LPS per UL/EN/IEC 60950-1 / CSA C22.2 no. 60950-1, or class 2 in

accordance with UL1310/UL1585 (NEC or CEC). The voltage supply must be suitable for operation above 2,000 m

should the pressure transmitter be used at this altitude.

Requirements for electrical connection

■

Cable diameter matches the cable bushing of the mating connector.

■

Cable gland and seals of the mating connector are correctly seated.

■

With cable outlets, no humidity can ingress at the cable end.

Requirement for shielding and grounding

The pressure transmitter must be shielded and grounded in accordance with the grounding concept of the plant.

Connecting the instrument

1. Assemble the mating connector or cable outlet.

→ For pin assignments, see product label

2

.

Establish the plug connection.

5. Commissioning, operation