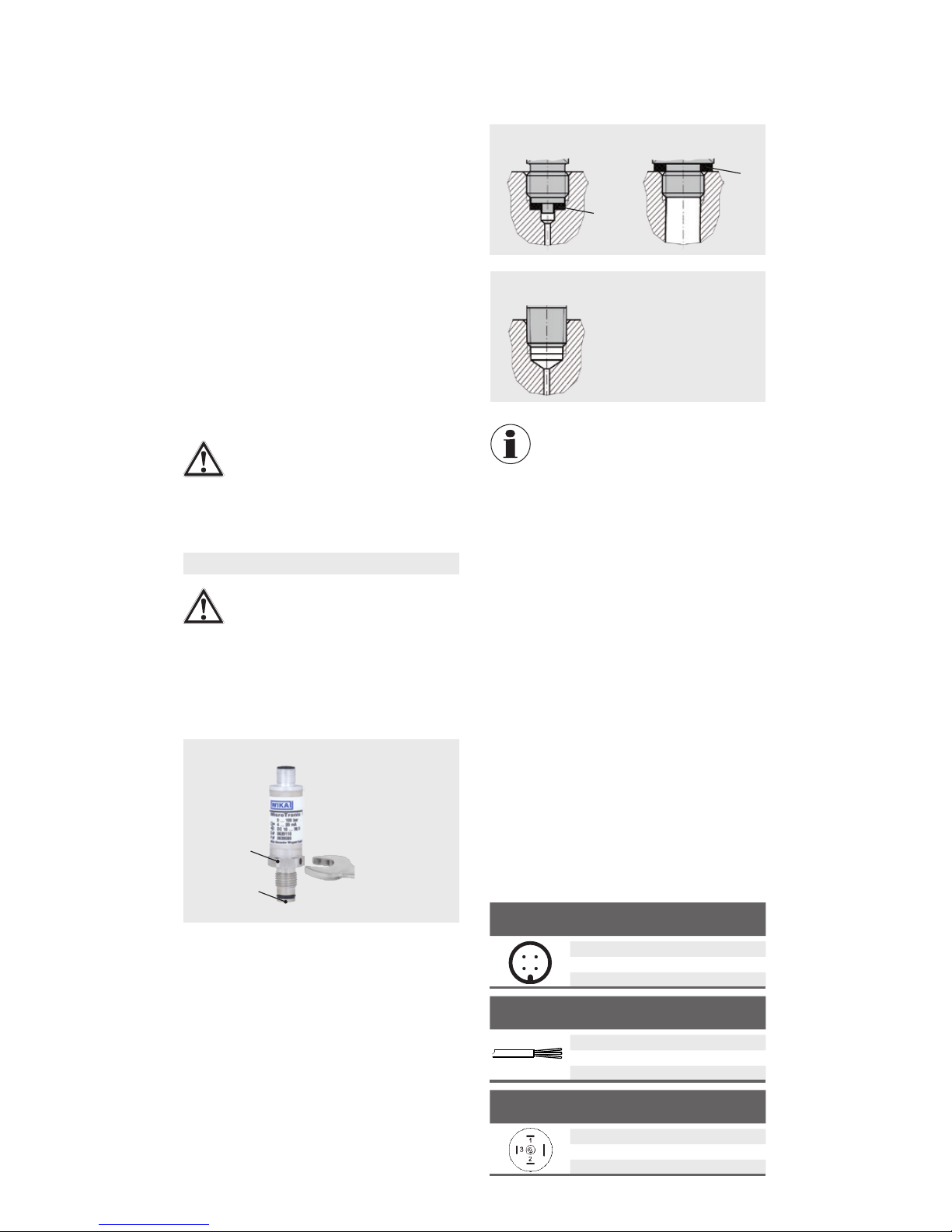

Circular connector M12 x 1 (4-pin)

2-wire 3-wire

UB

0V

S+-

Cable outlet, 2 m

2-wire 3-wire

UBbrown brown

0V green green

S+- white

43

12

Angular connector DIN 175301-803 C

2-wire 3-wire

UB

0V

S+-

5.2 Packaging

Do not remove packaging until just before mounting.

during transport (e.g. change in installation site, sending

for repair).

5.3 Storage

Permissible conditions at the place of storage:

Avoid exposure to the following factors:

Proximity to hot objects

Mechanical vibration, mechanical shock (putting it

down hard)

atmospheres

packaging is not available, pack and store the instrument

as described below:

Place the instrument, along with the shock-absorbent

material, in the packaging.

days), place a bag containing a desiccant inside the

packaging.

WARNING!

Before storing the instrument (following opera-

tion), remove any residual media.This is of

particular importance if the medium is hazard-

ous to health, e.g. caustic, toxic, carcinogenic,

radioactive, etc.

6. Commissioning, operation

CAUTION!

Prior to commissioning, the pressure transmit-

ter must be subjected to a visual inspection.

Check the diaphragm of the process

connection for any damage.

Only use the pressure transmitter if it is in

perfect condition with respect to safety.

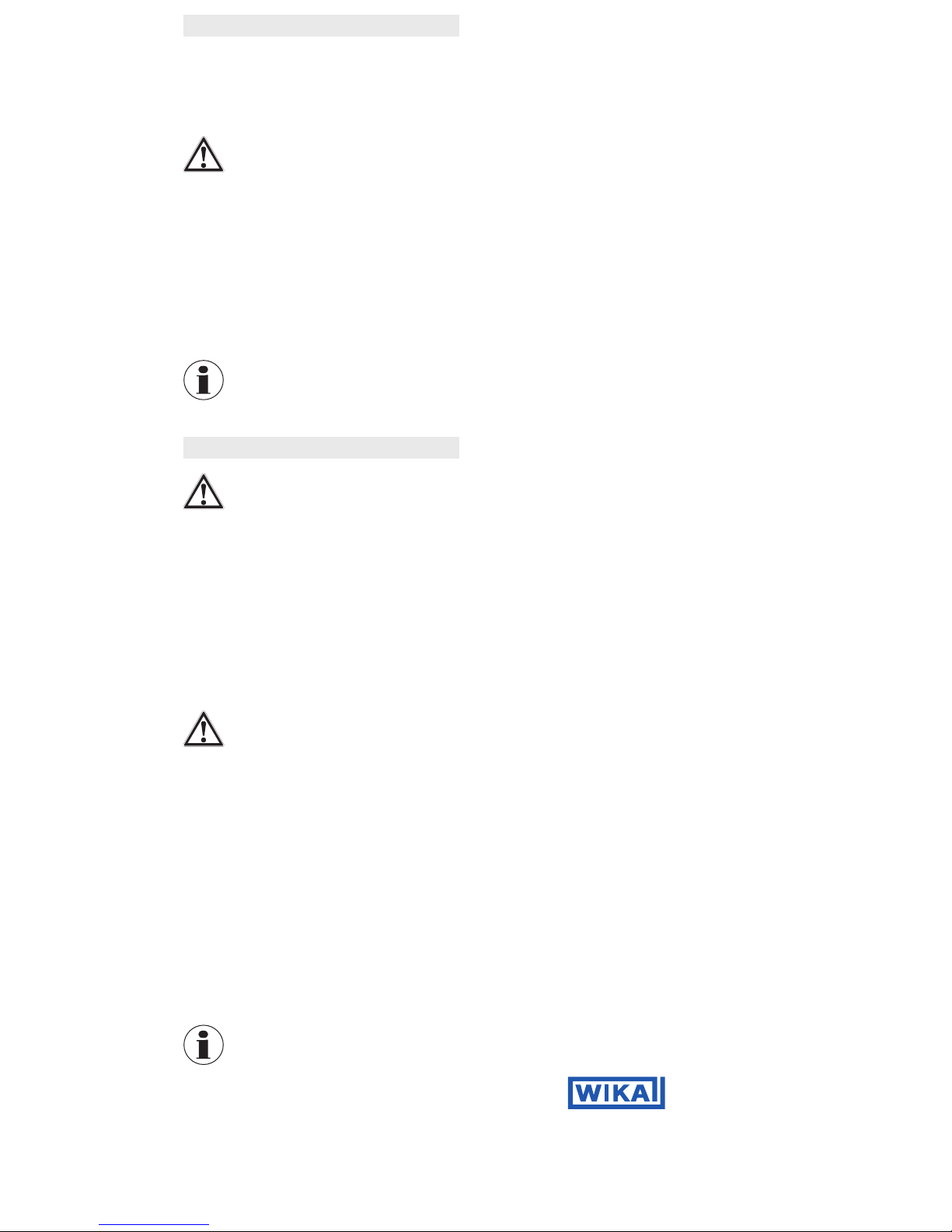

6.1 Mechanical mounting

Flush diaphragm

Sealing

Correct sealing of the process connections with parallel

threads at the sealing face must be made using suita-

sealing of tapered threads (e.g. NPT threads) is made by

providing the thread with additional sealing material such

6.2 Electrical mounting

The instrument must be grounded via the process

connection!

For instruments with voltage output, use shielded

leave the building, earth the shield at least at one end

of the cable.

at low voltages, which are separated from the power

recommended; alternatively protective measures from

America: The connection can be made in line with

-

ance with CEC (Canadian Electrical Code) or NEC

(National Electrical Code).

of the plug. Make sure that the cable gland of the

present and undamaged.Tighten the threaded connec-

tion and check that the seal is correctly seated, in order

to ensure the ingress protection.

For cable outlets, make sure that no moisture enters at

the cable end.

Remove the protection cap not until shortly before

installation.

Ensure that the diaphragm of the process connection

is not damaged during installation.

The sealing faces at the pressure transmitter and the

measuring point always have to be clean.

Only ever screw in, or unscrew, the instrument via

element as a working surface.

The correct torque depends on the dimensions of the

process connection, the gasket used (form/material)

and the measuring range (see illustration).

When screwing in, do not cross the threads.

For information on tapped holes and welding sockets,

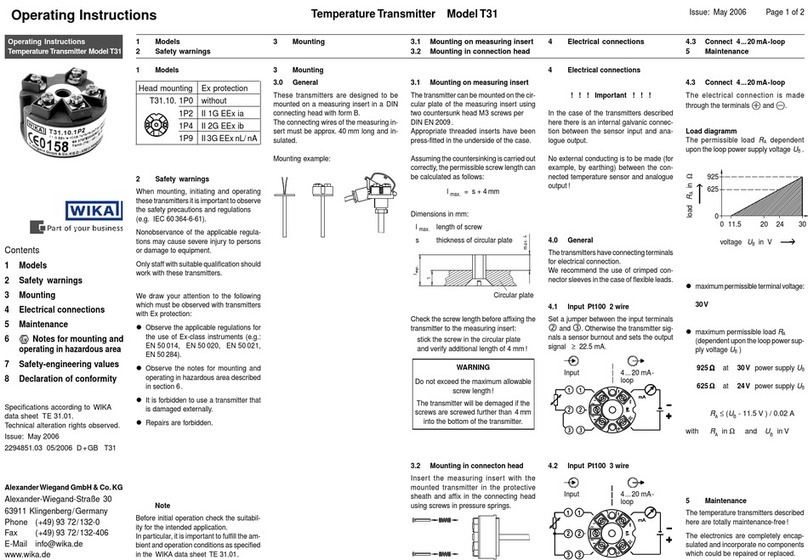

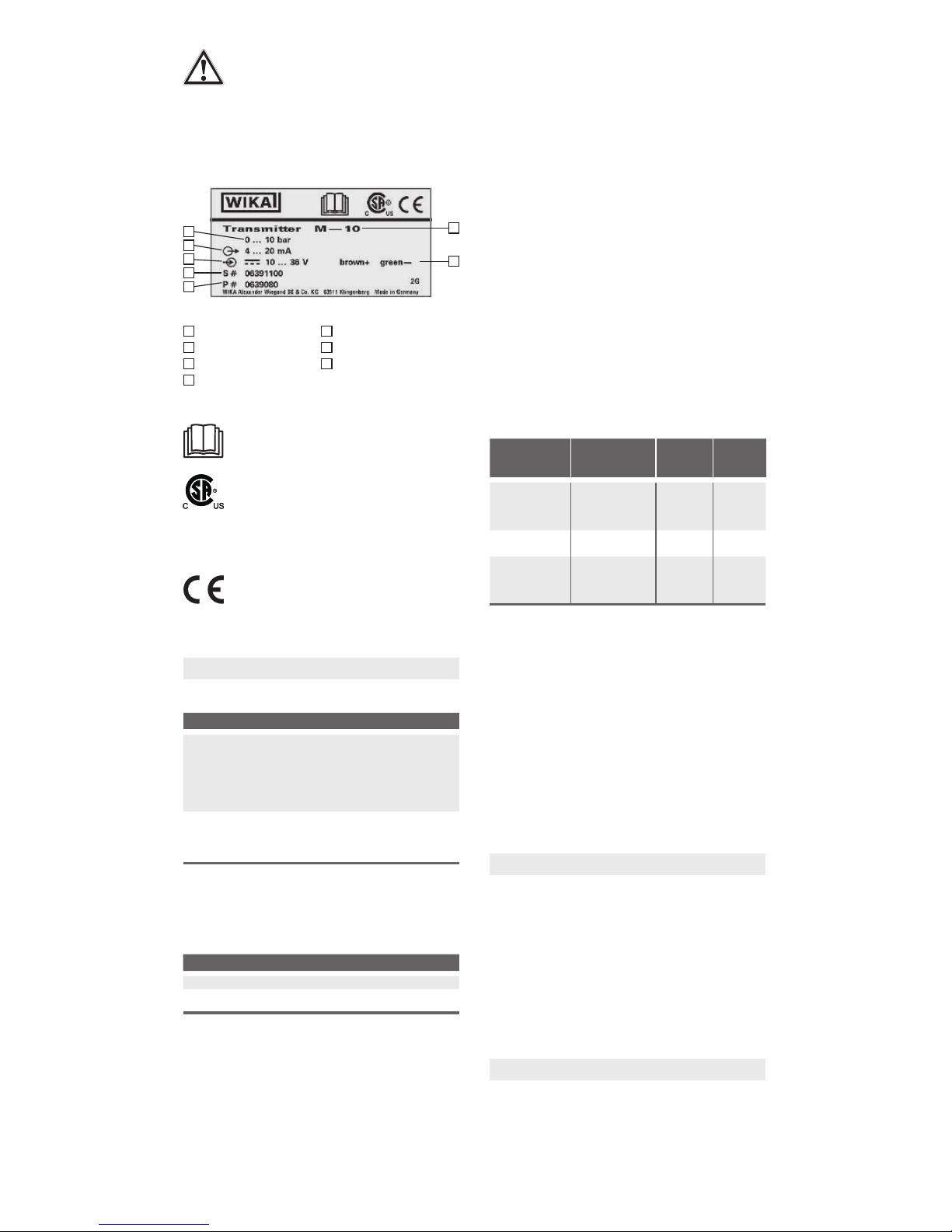

Connection diagrams

Maximum torque

Example, model M-11

Parallel thread

Tapered thread

NPT, R and PT