Page 1 of 5

006075 Revision M Date 03-08-11 JWC

1. READ AND FOLLOW ALL DIRECTIONS.

2. NEVER stand on table or INJURY MAY OCCUR.

3. NEVER allow user to sleep unattended on table or INJURY MAY OCCUR.

4. NEVER leave an unconscious user unattended on table or INJURY MAY OCCUR.

5. DO NOT use table for transporting user in or with ANY type of vehicle or trailer. Winco tables have not been tested

or approved for use by an occupant in any type of vehicle or trailer.

6. NEVER leave an infant or child unattended on table or INJURY MAY OCCUR.

7. DO NOT put hands, feet or clothing into any openings when changing positions on table. Attendant MUST confirm

that users hands and feet are safe while changing table positions or INJURY MAY RESULT.

8. Periodically, recheck tightness of all nuts, bolts and screws.

9. USE ONLY WINCO AUTHORIZED REPLACEMENT PARTS.

10. NEVER EXCEED the recommended weight capacity of 400 lbs. (181.4 kg).

11. SAVE THESE INSTRUCTIONS for future reference and training.

8570

Adjustable Headrest Treatment Table

CUSTOMER INSTRUCTIONS

Tools needed:

•Phillips-head screwdriver

•7/16” wrench (multiple size wrench included)

•Scissors or box cutter

•Cardboard shipping container (stays under table during assembly to protect upholstery)

•- If using powered tools always start hardware together by hand first & wear safety goggles

1. After checking your product for any shipping damage, table needs to be positioned upside-down on the

cardboard shipping container, or protective surface. Remove all packing material and hardware that was

secured for shipping. Cut tape on corners of box so that cardboard will lay flat while you assemble table.

2. You will find two Welded Leg Assemblies, one is attached to table frames and one is not.

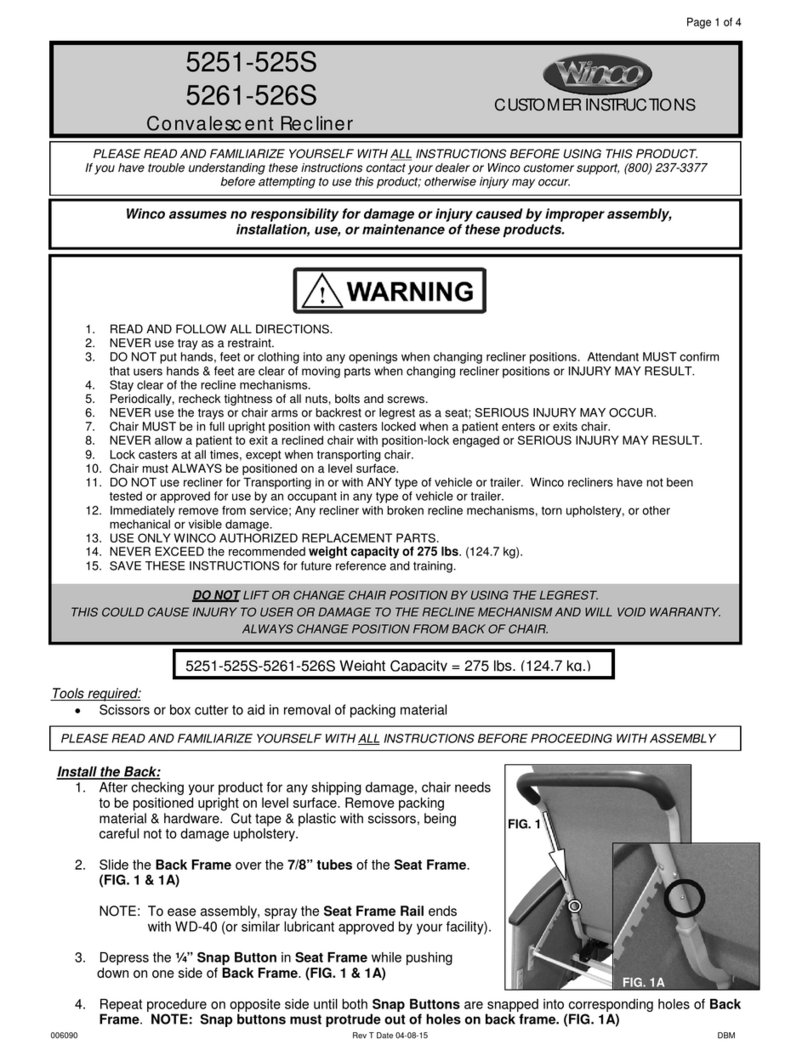

3. Pivot up the attached Welded Leg Assembly, (located on opposite end from the Backrest.)

4. Next, using a Phillips screwdriver, install (2) ¼-20 x 1-½” screws through the cross brace on Welded Leg

Assembly into (2) threaded holes in the wood bottom of Upholstered Top, as shown.

5. Install the unattached Welded Leg Assembly, on the end near the Backrest, as shown in picture. The cross

brace needs to be positioned toward “backrest end” of table.

6. Install (2) ¼-20 x 2-½” screws and (2) ¼-20 nuts to fasten the unattached Welded leg Assembly to the Table

Frame Rails. Heads of screws should face the sides of table, for better appearance. DO NOT FULLY

TIGHTEN AT THIS TIME.

PLEASE READ AND FAMILIARIZE YOURSELF WITH

LL

NSTRUCTIONS BEFORE PROCEEDING WITH ASSEMBLY

PLEASE READ AND FAMILIARIZE YOURSELF WITH ALL INSTRUCTIONS BEFORE USING THIS PRODUCT.

If you have trouble understanding these instructions contact your dealer or Winco customer support, (800) 237-3377

before attempting to use this product; otherwise injury may occur.

Winco assumes no responsibility for damage or injury caused by improper assembly,

installation, use, or maintenance of these products.

8570 Weight Capacity = 400 lbs. (181.4 kg.)